Extraction method of magnolia officinalis extract

An extraction method and extraction technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as complex process and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for extracting magnolia bark extract, said magnolia bark extract comprising magnolol and honokiol, prepared according to the following method:

[0033] a) 100 g of dry root powder of Magnolia officinalis that has been crushed to more than 20 meshes is extracted 4 times with 12 times, 10 times, 8 times and 6 times of 90% ethanol successively, and the extraction temperature is 75° C. to obtain an extract; The extract is filtered, and the filtrate is concentrated to dryness at a vacuum pressure of -0.08Mpa and a temperature of 50°C to obtain a concentrate;

[0034] b) Add 60 mL of ethyl acetate to the concentrate obtained in step a) to dissolve the concentrate, add 3 g of activated carbon to decolorize after dissolving, and concentrate to dryness at a vacuum pressure of -0.07Mpa and a temperature of 40°C to obtain crude Extract;

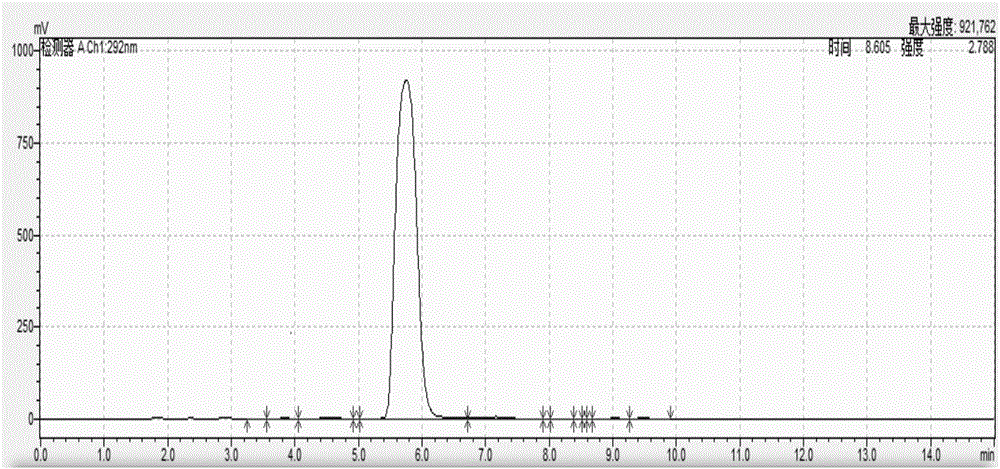

[0035] c) After dissolving the crude extract obtained in step b) with a mixed solvent of cyclohexane-ethyl acetate at a ratio of 5:1, ...

Embodiment 2

[0045] A method for extracting magnolia bark extract, said magnolia bark extract comprising magnolol and honokiol, prepared according to the following method:

[0046]a) 100 g of dry root powder of Magnolia officinalis that has been crushed to more than 20 meshes is extracted 4 times with 12 times, 10 times, 8 times and 6 times of 90% ethanol successively, and the extraction temperature is 80° C. to obtain an extract; The extract was filtered, and the filtrate was concentrated to dryness at a vacuum pressure of -0.086Mpa and a temperature of 55°C to obtain a concentrate;

[0047] b) Add 60 mL of ethyl acetate to the concentrate obtained in step a) to dissolve the concentrate, add 5 g of 200-mesh silica gel after dissolving to decolorize, and concentrate to dryness at a vacuum pressure of -0.07Mpa and a temperature of 45°C to obtain crude extract;

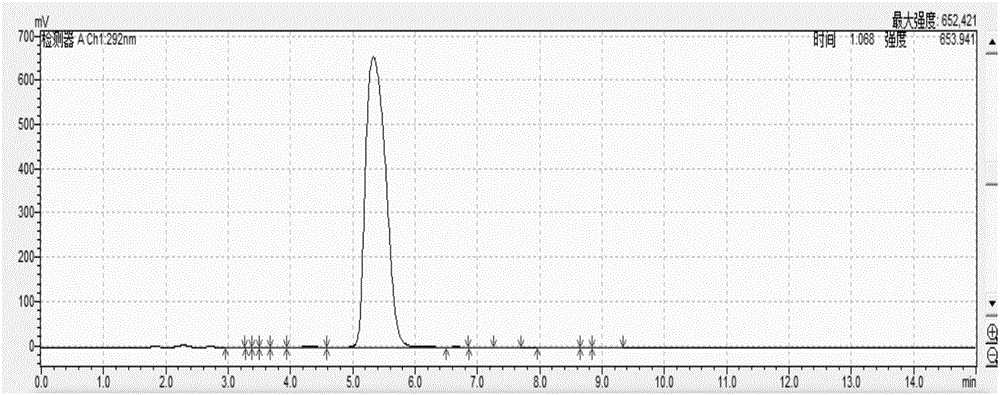

[0048] c) The crude extract obtained in step b) was dissolved in a mixed solvent of cyclohexane-ethyl acetate at a ratio of 5:1, ...

Embodiment 3

[0057] A method for extracting magnolia bark extract, said magnolia bark extract comprising magnolol and honokiol, prepared according to the following method:

[0058] a) 100 g of dry root powder of Magnolia officinalis that has been crushed to more than 20 meshes is extracted 4 times with 12 times, 10 times, 8 times and 6 times of 90% ethanol successively, and the extraction temperature is 85° C. to obtain an extract; The extract was filtered, and the filtrate was concentrated to dryness at a vacuum pressure of -0.09Mpa and a temperature of 60°C to obtain a concentrate;

[0059] b) Add 60 mL of ethyl acetate to the concentrate obtained in step a) to dissolve the concentrate, add 5 g of diatomaceous earth to decolorize after dissolving, and concentrate to dryness at a vacuum pressure of -0.08Mpa at a temperature of 50°C to obtain a crude extract ;

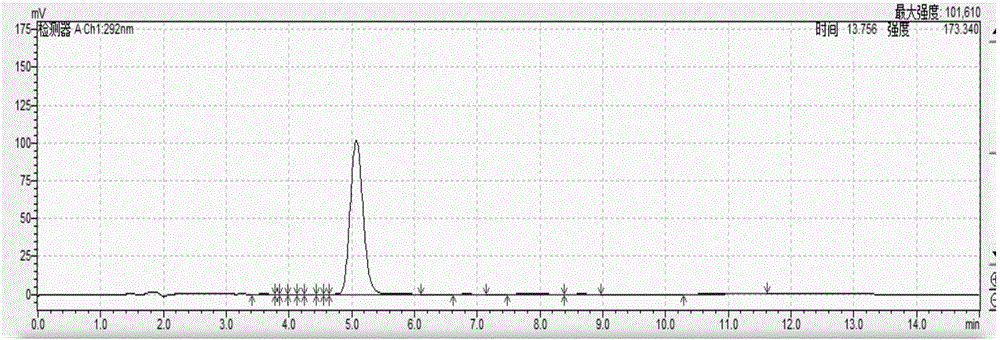

[0060] c) After dissolving the crude extract obtained in step b) with a mixed solvent of cyclohexane-ethyl acetate at a ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com