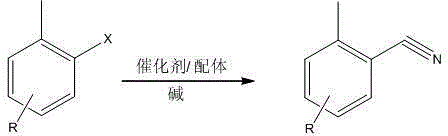

Method for preparing high-purity methylbenzenecarbonitrile and derivatives thereof

A technology of o-toluonitrile and o-methyl bromobenzene is applied in the field of preparation of high-purity o-toluonitrile and derivatives thereof, and can solve the problems of long reaction time, low product yield and purity, pollution of three wastes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 3g of sodium carbonate and 0.0025g of palladium acetate into 11mL of anhydrous N-methylpyrrolidone (NMP), stir, add 0.003g of dppf (1,1 diphenylphosphinoferrocene), heat up to 100°C, and Add the grams of 2-bromo-5-fluorotoluene and the same molar amount of sodium carbonate, add potassium ferrocyanide (K 4 [Fe(CN) 6 ]) 2g, reacted under nitrogen protection for 13 hours, quenched with 35mL water, extracted with 30mL×3 n-hexane, washed with 30mL×3 saturated brine, dried over anhydrous sodium sulfate for 12h, and spin-dried the solvent under reduced pressure to obtain the crude product. Take 2g of the crude product In a three-necked flask, add ethers (petroleum ether) or a mixture of petroleum ether and methyl tert-butyl ether 5mL, heat up and stir to 40°C, dissolve the crude product, cool to 20°C, stir for 2h, then stir in an ice bath for 0.5h , filtered, washed the filter cake with cold petroleum ether, and dried the filter cake under reduced pressure to obtain 1.7g ...

Embodiment 2

[0032] Add 5g of sodium carbonate and 0.004g of palladium acetate into 20mL of anhydrous N,N-dimethylacetamide (DMAC), stir, add 0.005g of dppf (1,1 diphenylphosphinoferrocene) and heat up to 130 ℃, add 2-bromo-5-fluorotoluene and sodium carbonate in the same molar amount 9g at one time, add potassium ferrocyanide (K 4 [Fe(CN) 6 ]) 3.75g, heat preservation reaction for 11 hours, quenched with 30mL water, extracted with 50mL×3 n-hexane, washed with 50mL×3 saturated brine, dried over anhydrous magnesium sulfate for 12h, and spin-dried the solvent under reduced pressure to obtain a crude product, 5.8g Put the crude product in a three-necked flask, add 15 mL of ether (petroleum ether) or a mixture of petroleum ether and methyl tert-butyl ether, heat up and stir to 40°C, dissolve the crude product, cool to 20°C, stir for 2h, and then stir in an ice bath for 1h. Filter, wash the filter cake with cold petroleum ether, and dry the filter cake under reduced pressure to obtain 4.8 g of...

Embodiment 3

[0035] Add 2.5g of sodium carbonate and 0.002g of palladium acetate into 10mL of anhydrous N,N-dimethylacetamide (DMAC), stir, add 0.0025g of dppf (1,1 diphenylphosphinoferrocene), and heat up to 130°C, add 4.5g of 2-bromo-5-fluorotoluene and sodium carbonate at one time, add potassium ferrocyanide (K 4 [Fe(CN) 6 ]) 1.88g, heat preservation reaction for 11 hours, quenched with 15mL water, extracted with 30mL×3 n-hexane, washed with 30mL×3 saturated saline, dried over anhydrous magnesium sulfate for 12h, and spin-dried under reduced pressure to obtain a crude product, 2.9g Put the crude product in a three-necked flask, add ethers (petroleum ether) or 8 mL of a mixture of petroleum ether and methyl tert-butyl ether, heat up and stir to 40°C, dissolve the crude product, cool to 20°C, stir for 2h, then stir in an ice bath for 1h, Filter, wash the filter cake with cold petroleum ether, and dry the filter cake under reduced pressure to obtain 2.6 g of the product.

[0036] The rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com