Method for preparing carboxymethyl cellulose with different substitution degrees from waste soybean straws

A technology for carboxymethyl cellulose and soybean straw, which is applied to the field of preparing carboxymethyl cellulose with different degrees of substitution from waste soybean straw, can solve the problems of single process step design and reaction conditions, increased process complexity, complex pretreatment process and the like , to achieve the effect of reasonable response time, reducing environmental burden, and broadening application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

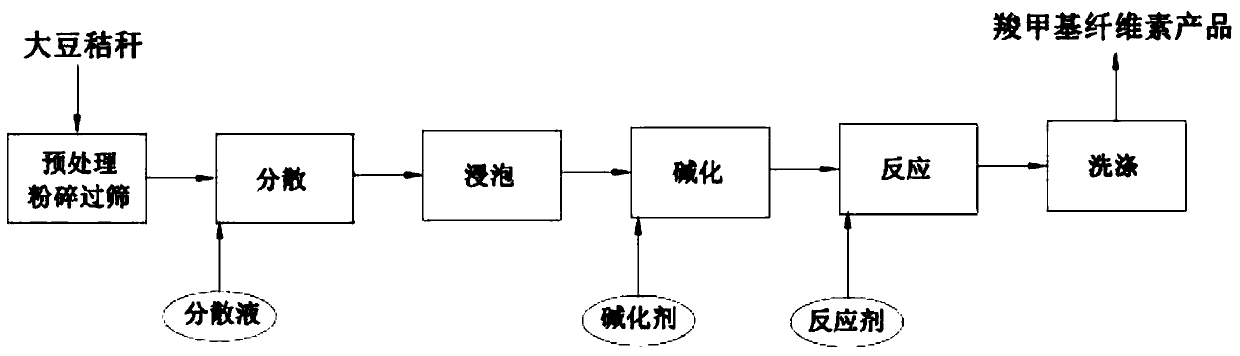

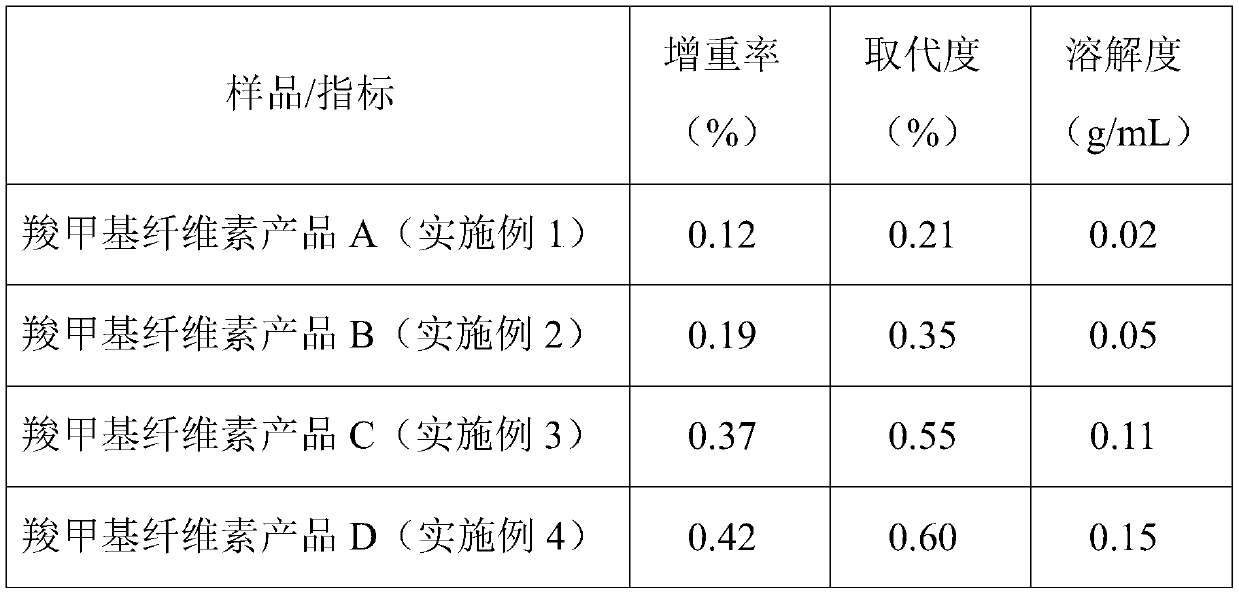

[0040] Embodiment 1: as figure 1 As shown, weigh 1.0g of sodium hydroxide, measure 39mL of deionized water, and prepare a 2.5% sodium hydroxide solution, weigh 5.0g of waste soybean straw powder that has passed through a 100 mesh sieve, and mix the soybean straw powder with the The sodium hydroxide solution was mixed evenly in a three-necked bottle, and soaked for 12 hours. Then weigh 5.0 g of sodium hydroxide and measure 15 mL of deionized water to prepare a sodium hydroxide solution, add it dropwise to the above-mentioned three-neck flask, and heat in a water bath at 30° C. for 1.5 h. Weigh 1.84g of chloroacetic acid and 1.03g of sodium carbonate, measure 10mL of deionized water, prepare sodium chloroacetate solution, add dropwise to the above solution, adjust the temperature of the water bath to 35°C, and pour the solution into a stainless steel plate after reacting for 30 minutes , heated in an oven at 70°C for 2 hours, dried, pulverized, washed with 70% ethanol, dried an...

Embodiment 2

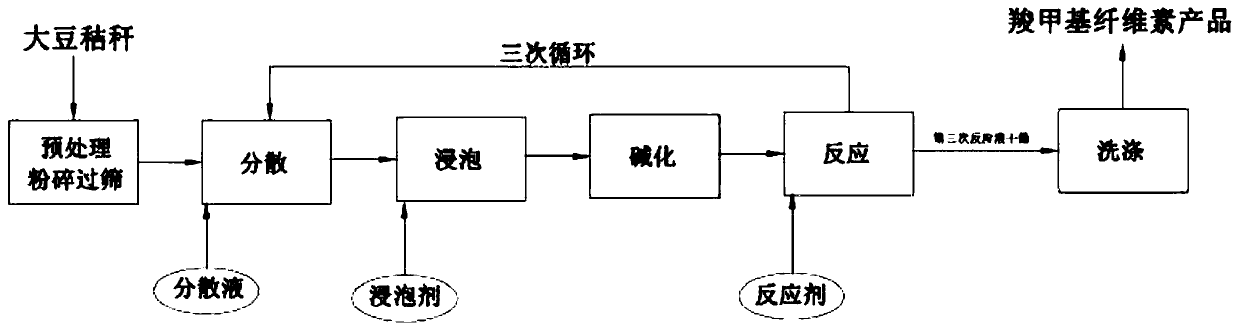

[0041] Embodiment 2: as figure 2 As shown, measure 50.0 mL of deionized water into the reaction vessel, weigh 10 g of soybean straw powder, and add soybean straw powder passed through a 100-mesh sieve under constant stirring. Weigh 1.00g of sodium hydroxide and dissolve it in 5mL of deionized water. After the heat release is complete and the sodium hydroxide is completely dissolved, add it to the reaction vessel and soak for 6 hours, then raise the temperature to 30°C for 1.5 hours of alkalization under constant stirring, accurately Weigh 3.595g of sodium chloroacetate and dissolve it in 10mL of deionized water, raise the temperature to 75°C, slowly add the above solution under stirring to etherify for 60min, dry and crush to 100 mesh, repeat the above steps three times, wash with 70% ethanol, dry and crush Obtain carboxymethyl cellulose product B.

Embodiment 3

[0042] Embodiment 3: as figure 1 As shown, weigh 1.0g of sodium hydroxide, measure 39mL of deionized water, and prepare a 2.5% sodium hydroxide solution, weigh 5.0g of soybean straw powder passed through a 100-mesh sieve, and mix the soybean straw powder with hydrogen The sodium oxide solution was mixed evenly in a three-necked bottle, and soaked for 12 hours. Then weigh 5.2 g of sodium hydroxide and measure 15 mL of deionized water to prepare a sodium hydroxide solution, add it dropwise to the above-mentioned three-neck flask, and heat in a water bath at 30° C. for 1.5 h. Weigh 7.34g of chloroacetic acid and 4.12g of sodium carbonate, measure 10mL of deionized water, prepare sodium chloroacetate solution, add it dropwise to the above mixture, adjust the temperature of the water bath to 35°C, and pour the mixture into a stainless steel plate after reacting for 30 minutes , heated in an oven at 70°C for 2 hours, dried, pulverized, washed, washed with 70% ethanol, dried and pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com