High-shading-degree white PPR pipe and preparation method thereof

A technology for luminosity and pipes, which is applied in the field of high-shading white PPR pipes and its preparation, to achieve the effects of improving temperature and pressure resistance, reducing light transmittance, and improving light shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

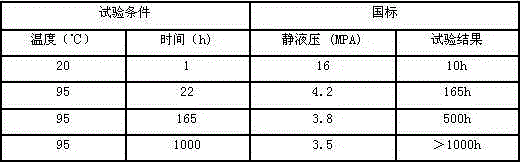

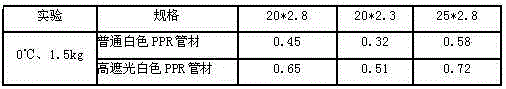

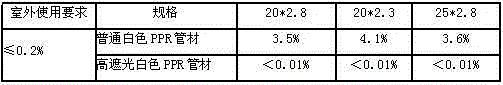

Examples

Embodiment 1

[0029] Example 1: Preparation of high shading white PPR pipe

[0030] Step 1) Preparation of pipe additive masterbatch: 10 kg of PPR pipe material, 200 g of antioxidant 1010, 400 g of antioxidant 1130, 400 g of phosphite antioxidant 168, 150 g of hydroxybenzotriazole Put UV-like absorber 234, 150 grams of hindered amine light stabilizer 770 and 5 grams of light cut-off agent 7276A that blocks 350-800nm wavelength into a mixer with a speed of 50-100 rpm, and then measure 10-15ml of white oil , after stirring for 10 minutes, feed to the twin-screw extruder granulator to obtain the pipe additive masterbatch.

[0031] Step 2) Preparation of high-shading white masterbatch: Pour 100kg of PPR powder, 3000g of PE wax, 500g of Kao diffusion powder EBS, and 30kg of shading agent rutile titanium dioxide into a 150L high-speed mixer , 90 grams of aluminum silver powder, and then measure 100ml of diffusion oil, first mix at low speed for 2 minutes, the mixing temperature is 30~40°C, to ...

Embodiment 2

[0033] Example 2: Preparation of high shading white PPR pipe

[0034] Step 1) Preparation of pipe additive masterbatch: 10 kg of PPR pipe material, 200 g of antioxidant 1010, 400 g of antioxidant 1130, 400 g of phosphite antioxidant 168, 100 g of hydroxybenzotriazole Put UV-like absorber 234, 100 grams of hindered amine light stabilizer 770 and 4.8 grams of light cut-off agent 7276F that blocks 350-850nm wavelength into a mixer with a speed of 50-100 rpm, and then measure 10-15ml of white oil , after stirring for 10 minutes, feed to the twin-screw extruder granulator to obtain the pipe additive masterbatch.

[0035] Step 2) Preparation of high-shading white masterbatch: Pour 100kg of PPR powder, 3000g of PE wax, 500g of Kao diffusion powder EBS, and 24kg of shading agent rutile titanium dioxide into a 150L high-speed mixer 1. 95 grams of aluminum silver powder, then measure 100ml of diffusion oil, first mix at low speed for 2 minutes, the mixing temperature is 30~40°C, to pro...

Embodiment 3

[0038] Step 1) Preparation of pipe additive masterbatch: 10 kg of PPR pipe material, 200 g of antioxidant 1010, 400 g of antioxidant 1130, 400 g of phosphite antioxidant 168, 120 g of hydroxybenzotriazole Put UV-like absorber 234, 120 grams of hindered amine light stabilizer 770 and 4.2 grams of light cut-off agent 7276E that blocks 350-950nm wavelength into a mixer with a speed of 50-100 rpm, and then measure 10-15ml of white oil , after stirring for 10 minutes, feed to the twin-screw extruder granulator to obtain the pipe additive masterbatch.

[0039] Step 2) Preparation of high-shading white masterbatch: Pour 100kg of PPR powder, 3000g of PE wax, 500g of Kao diffusion powder EBS, and 35kg of opacifying agent rutile titanium dioxide into a 150L high-speed mixer , 80 grams of aluminum silver powder, and then measure 100ml of diffusion oil, first mix at low speed for 2 minutes, the mixing temperature is 30~40°C, to promote the pre-dispersion of the mixture, so that various ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com