Long-acting nano-hydrophobic coating composition and preparation method thereof

A technology of hydrophobic coating and composition, applied in the direction of coating, etc., can solve the problem of glass not easy to adhere to water, etc., achieve strong water repelling effect and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

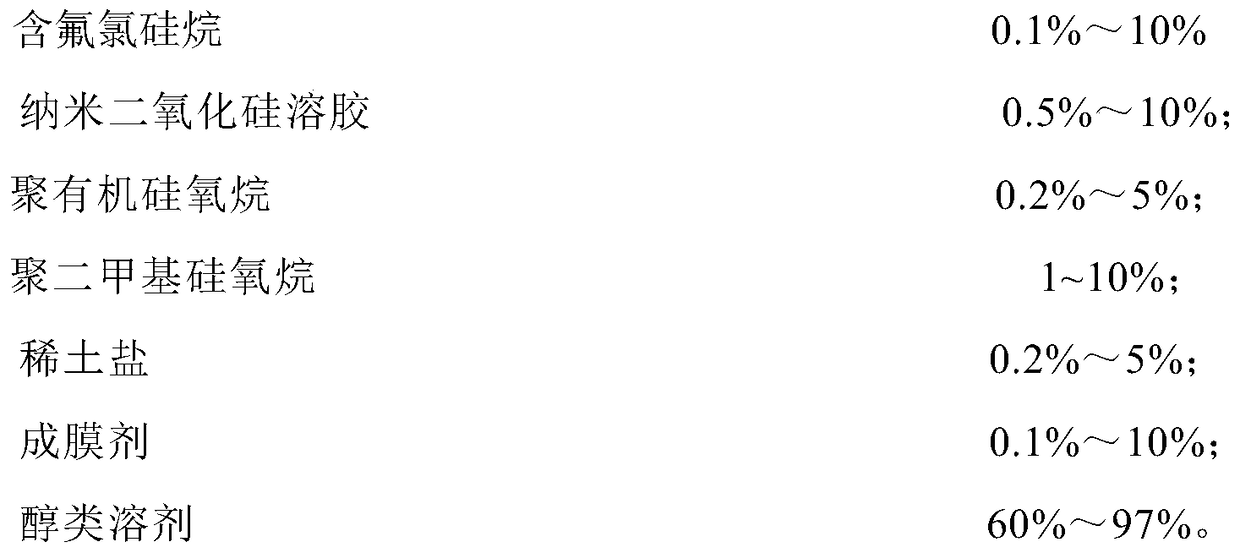

Method used

Image

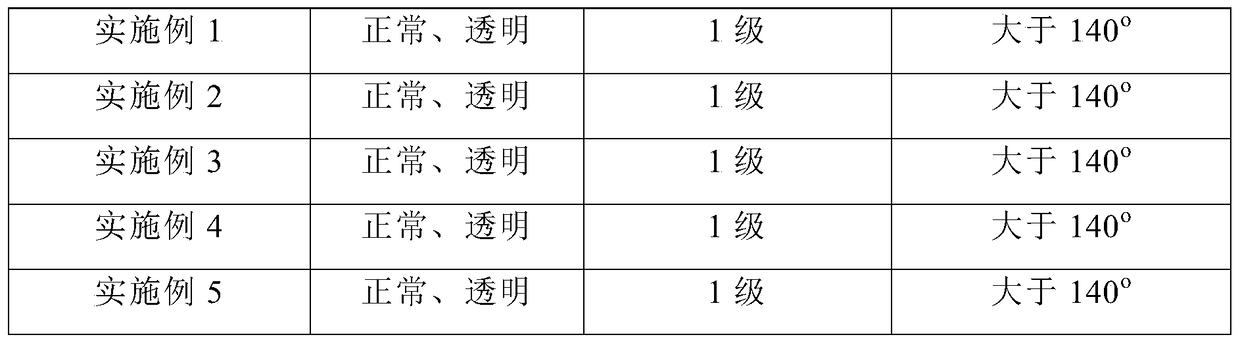

Examples

Embodiment 1

[0024] The preparation method of the long-acting nano-hydrophobic coating of the present embodiment comprises the steps:

[0025] 1. Preparation of nano-silica sol: Proportion the following raw materials according to weight percentage, 1% ethyl orthosilicate, 0.1% deionized water, 0.1% polyvinylpyrrolidone, 0.01% nitric acid and 98.79% ethanol, mix at 60°C Stir for 2 hours.

[0026] 2. The ingredients are formulated according to the following weight percentages: add 1wt% trifluoropropyl trichlorosilane (Shanghai Yiji Industrial Co., Ltd.), 1wt% 202 methyl silicone oil (Qingdao Zhongbao Chemical Co., Ltd.) to 5wt% nano-silica sol at 60 ° C Co., Ltd.), 1wt% 201 methyl silicone oil (Qingdao Xingye Organic Silicon New Material Co., Ltd.), 3wt% lanthanum nitrate, 3wt% ethylene glycol butyl ether and 86wt% ethanol, mixed and stirred for 4 hours to obtain a long-lasting nano-hydrophobic coating .

[0027] 3. Spray the prepared long-acting nano-hydrophobic coating on the clean and d...

Embodiment 2

[0029] The preparation method of the long-acting nano-hydrophobic coating of the present embodiment comprises the steps:

[0030] 1. Prepare nano-silica sol: Proportion the following raw materials according to weight percentage, 10% ethyl orthosilicate, 5% deionized water, 5% polyvinylpyrrolidone, 1% hydrochloric acid and 79% ethanol, mix at 60°C Stir for 4 hours.

[0031] 2. The ingredients are formulated according to the following weight percentages: add 10wt% dimethyl perfluorooctyl silane chloride (Shanghai Chuqing New Material Technology Co., Ltd.), 5wt% 202 hydrogen-containing silicone oil to 5wt% nano-silica sol at 30°C (Qingdao Zhongbao Chemical Co., Ltd.), 5wt% 201 methyl silicone oil (Qingdao Xingye Organic Silicon New Material Co., Ltd.), 0.2wt% cerium nitrate, 10wt% ethylene glycol ether and 64.8wt% n-propanol, mixed and stirred for 7 hours , to obtain long-lasting nano-hydrophobic coatings.

[0032] 3. Spray the prepared long-acting nano-hydrophobic coating on t...

Embodiment 3

[0034] The preparation method of the long-acting nano-hydrophobic coating of the present embodiment comprises the steps:

[0035] 1. Prepare nano-silica sol: Proportion the following raw materials according to weight percentage, 6% tetraethyl orthosilicate, 3% deionized water, 3% polyvinylpyrrolidone, 0.4% hydrochloric acid and 87.6% ethanol, mix at 60°C Stir for 6 hours.

[0036] Two, according to the following weight percentage batching: according to the following weight percentage batching: 5wt% nano silica sol is added 5wt% trifluoropropyl methyl dichlorosilane (Jinan Tengyuan Chemical Technology Co., Ltd.), 3wt% 202 hydrogen-containing silicone oil (Qingdao Zhongbao Chemical Co., Ltd.), 2wt% 204 methyl silicone oil (Nanchang Wanhe Silicone Products Co., Ltd.), 0.3wt% neodymium nitrate, 6wt% propylene glycol ether and 78.7wt% isopropanol, mixed and stirred After 2 hours, a long-lasting nano-hydrophobic coating can be obtained.

[0037] 3. Spray the prepared long-acting n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com