Saline-alkali soil improvement agent and preparation method and application thereof

A technology of improver and saline-alkali land, which is applied in the preparation of saline-alkali land improver and its preparation field by using phosphogypsum, can solve the problems of inability to be popularized in a large area, high cost, complicated production process, etc., and achieve suitable crop growth, low cost, and improved The effect of soil salinity drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

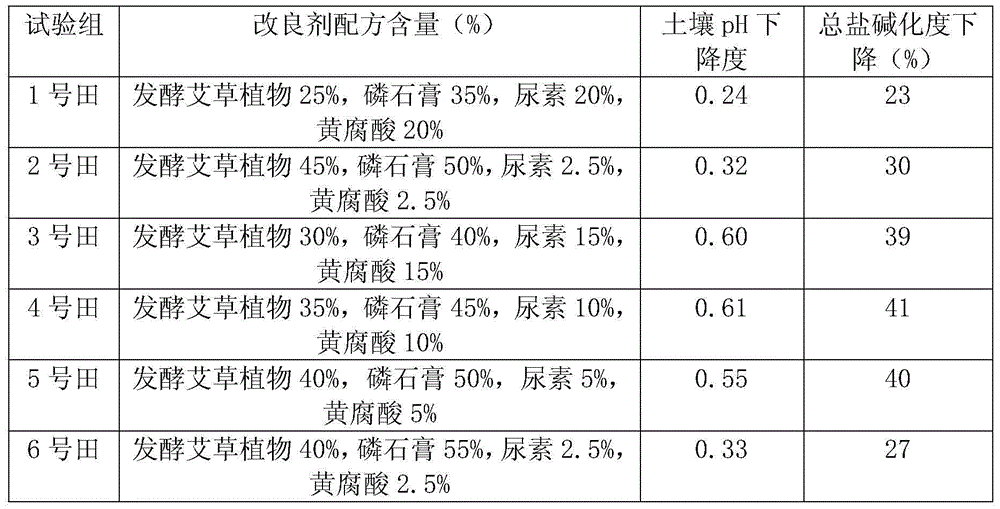

Embodiment 1

[0038] Embodiment 1: Preparation of composite improver of the present invention

[0039](1) Cut the picked wormwood plant into 2-4cm long, put it into the fermentation tank, put the soaking liquid inoculated with cellulolytic enzymes into the pool for retting, submerge in the soaking liquid, stir once every 4 days, after 30 days , clearing out the wormwood plants, drying them in the sun, and crushing them to obtain fermented wormwood plants for later use;

[0040] (2) Phosphogypsum is pulverized to a particle size of less than 1 mm, and set aside;

[0041] (3) By fermented wormwood plant: phosphogypsum after pulverizing: urea: fulvic acid=30%: 40%: 15%: 15% mixed, and add 20% water of mixed material and mix evenly, after mixing Carry out granulation with a granulator, dry until the water content of the material is 8%, and then sieve to obtain finished granules with a particle size of 5-8 mm, which is the prepared improver of the present invention.

Embodiment 2

[0042] Embodiment 2: the preparation of composite improver of the present invention

[0043] (1) Cut the picked wormwood plant into 2-4cm long, put it into the fermentation tank, put the soaking liquid inoculated with cellulolytic enzymes into the pool for retting, soak the soaking liquid, stir once every 4 days, after 35 days , clearing out the wormwood plants, drying them in the sun, and crushing them to obtain fermented wormwood plants for later use;

[0044] (2) Phosphogypsum is pulverized to a particle size of less than 1 mm, and set aside;

[0045] (3) mix by fermented wormwood plant: phosphogypsum after pulverizing: urea: fulvic acid=35%: 45%: 10%: 10%, and add 25% water of mixed material weight to mix evenly, mix Then granulate with a granulator, dry until the water content of the material is 5%, and then sieve to obtain finished granules with a particle size of 5-8mm, which is the improved agent of the present invention.

Embodiment 3

[0046] Embodiment 3: the preparation of composite improver of the present invention

[0047] (1) Cut the picked wormwood plant into 2-4cm long, put it into the fermentation tank, put the soaking liquid inoculated with cellulolytic enzymes into the pool for stack retting, soak the soaking liquid, stir once every 4 days, after 40 days , clearing out the wormwood plants, drying them in the sun, and crushing them to obtain fermented wormwood plants for later use;

[0048] (2) Phosphogypsum is pulverized to a particle size of less than 1 mm, and set aside;

[0049] (3) mix by fermented wormwood plant: pulverized phosphogypsum: urea: fulvic acid=40%: 50%: 5%: 5%, and add 30% water of mixed material weight to mix evenly, mix Finally, carry out granulation with a granulator, dry until the water content of the material is 3%, and then sieve to obtain finished granules with a particle size of 5-8 mm, which is the prepared improver of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com