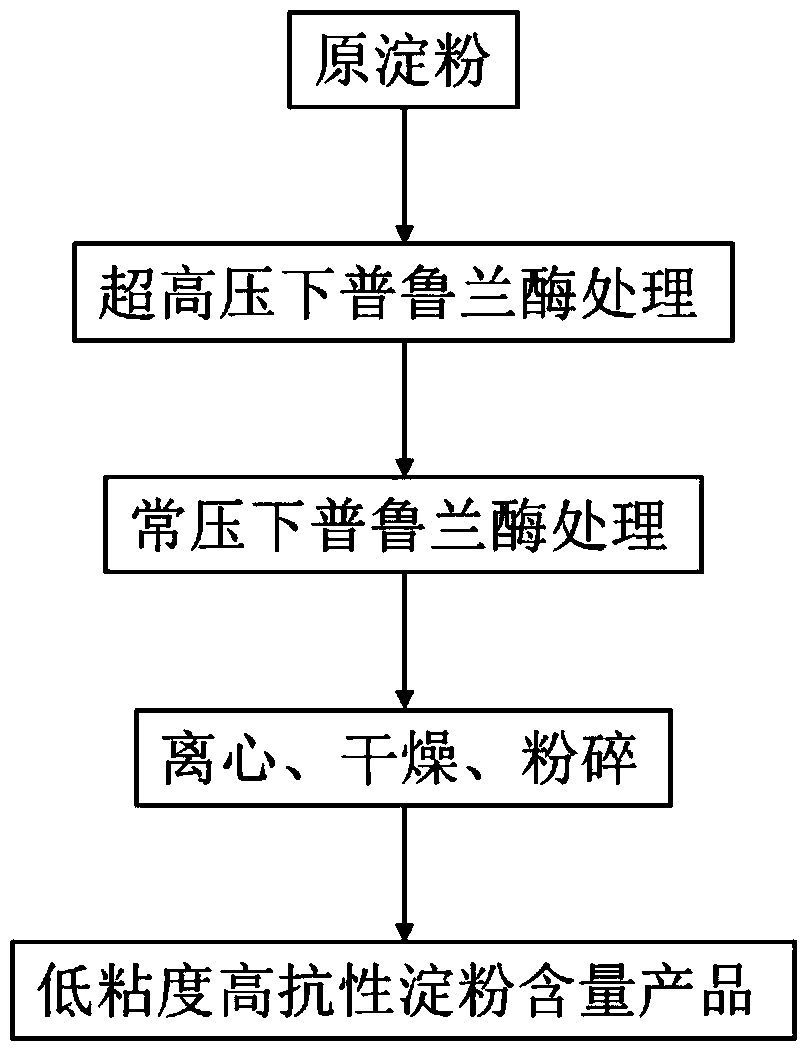

A product rich in low-viscosity resistant starch and its preparation method

A resistant starch and low-viscosity technology, which is applied in the field of products rich in low-viscosity resistant starch and its preparation, can solve the problems of unfavorable industrial production, long production cycle, complicated operation, etc., and achieve easy industrial production and low cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of products rich in low-viscosity resistant starch

[0030] 1) Mix the original starch and pH 5.5 buffer at a mass volume ratio of 1:10 (w / v, g / mL), add pullulanase at the concentration ratio of enzyme to substrate 160 U / g and pour into vacuum packaging Inside the bag and seal; put the sample in the ultra-high pressure equipment, set the pressure of the ultra-high pressure equipment to 400MPa, and enzymatically hydrolyze at 60°C for 40 minutes.

[0031] 2) Put the sample obtained in step 1) under normal pressure at 60°C and continue enzymatic hydrolysis for 10 hours at a stirring speed of 130rpm, and then passivate the enzyme activity in an ice bath at 4°C for 10 minutes, centrifuge to remove the supernatant, dry and grind Powder and sieving to obtain products with low viscosity and high resistant starch content.

Embodiment 2

[0032] Example 2: Preparation of products rich in low-viscosity resistant starch

[0033] 1) Mix the raw starch and pH 5.5 buffer solution at a mass volume ratio of 1:10 (w / v, g / mL), add pullulanase according to the concentration ratio of enzyme to substrate 320 U / g and pour it into vacuum packaging Inside the bag and seal; put the sample into an ultra-high pressure device, set the pressure of the ultra-high pressure device to 200 MPa, and enzymatically hydrolyze at 60°C for 40 minutes.

[0034] 2) Put the sample obtained in step 1) under normal pressure at 60°C and continue enzymatic hydrolysis for 10 hours at a stirring speed of 130rpm, and then passivate the enzyme activity in an ice bath at 4°C for 10 minutes, centrifuge to remove the supernatant, dry and grind Powder and sieving to obtain products with low viscosity and high resistant starch content.

Embodiment 3

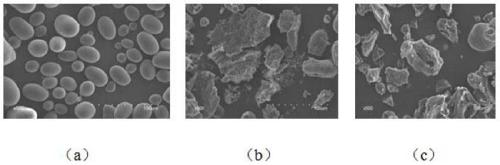

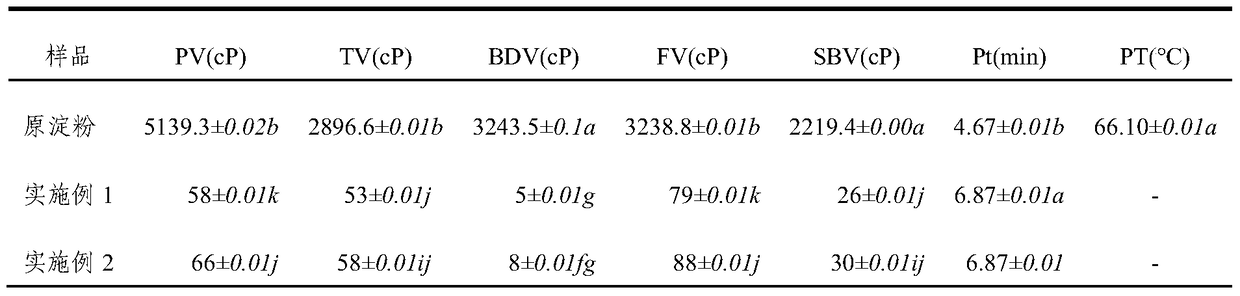

[0035] Example 3 Determination of gelatinization characteristics, resistant starch content and microstructure of products rich in low-viscosity resistant starch

[0036] 1) Determination of gelatinization properties

[0037] The rapid viscosity tester (RVA) was used to investigate the gelatinization characteristics of raw potato starch and products with low viscosity and high resistance starch content (Example 1 and Example 2). Accurately weigh 3.0g starch into the matching aluminum box, add 25ml distilled water and mix well. The operation is carried out with an immobilized heating-cooling program accompanied by a constant shear strain rate. The sample is kept at 50°C for 1 minute, heated to 95°C at a rate of 9.5°C / min, and held for 2.5 minutes, then cooled to 50°C at a rate of 11.84°C / min, and kept at 50°C for 2 minutes. The sample measurement time is 13 minutes. RVA viscosity curve of starch paste. Recording parameters include: Peak viscosity (PV), Trough viscosity (TV), Break...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com