Preparation method of alumina coating of silicon carbide fiber surface

A silicon carbide fiber, alumina coating technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of insufficient anti-oxidation performance, reduced performance of SiC materials, affecting service life, etc., and achieves large specific surface area and simple method. , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

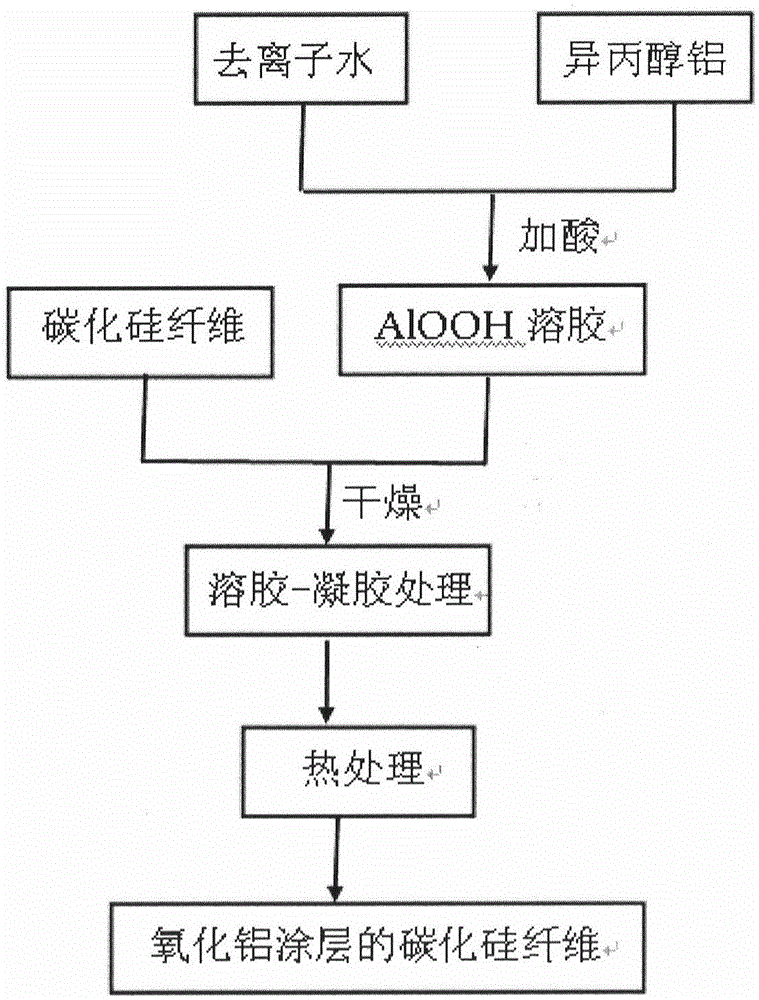

[0019] Add 400g of deionized water into the three-necked flask, heat it to 80°C, and put the pre-ground 4g of Al(OC 3 h 7 ) 3 Add the powder slowly, and stir at 90°C for 2 hours after the addition, so that the Al(OC 3 h 7 ) 3 Complete hydrolysis to form Al(OH) 3 Precipitate, make the C produced by the reaction as much as possible under stirring conditions 3 h 7 The OH is completely volatilized; then the peptizer HCl is added dropwise, and the pH value of the solution is controlled in the range of 3-4 to peptize the precipitate; finally, the stable and transparent AlOOH sol is obtained by aging for 16 hours under reflux and stirring at 90°C.

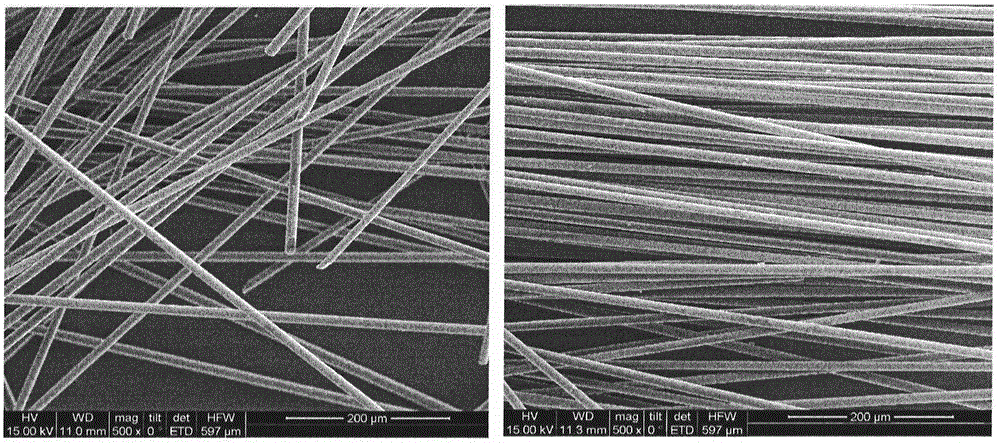

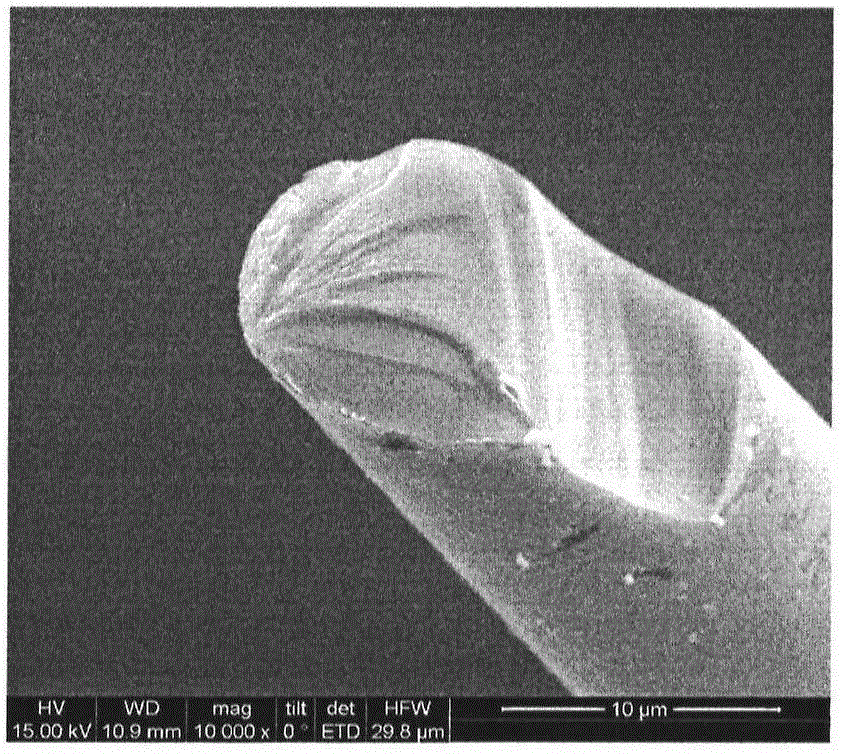

[0020] Soak uncoated SiC fibers in AlOOH sol for 2 hours, then dry at 100°C for 2 hours, and perform gelation treatment to obtain SiC fibers coated with AlOOH sol; place the above-treated SiC fibers in a tube furnace under nitrogen Under the condition of protection, heating to 800°C and keeping it for 2h, the Al 2 o 3 Coated SiC ...

Embodiment 2

[0022] Add 400g of deionized water into the three-necked flask, heat it to 80°C, and put the pre-ground 2g of Al(OC 3 h 7 ) 3 Add the powder slowly, and stir at 90°C for 2 hours after the addition, so that the Al(OC 3 h 7 ) 3 Complete hydrolysis to form Al(OH) 3 Precipitate, make the C produced by the reaction as much as possible under stirring conditions 3 h 7 The OH is completely volatilized; then the peptizer HCl is added dropwise to control the pH value of the solution in the range of 3-4 to peptize the precipitate; finally, the stable and transparent AlOOH sol is obtained by aging for 15 hours under reflux and stirring at 90°C.

[0023] Soak uncoated SiC fibers in AlOOH sol for 3 hours, dry at 95°C for 2 hours, and perform gelation treatment to obtain SiC fibers coated with AlOOH sol; place the treated SiC fibers in a tube furnace under nitrogen Under the condition of protection, heating to 700°C and keeping it for 2h, the Al 2 o 3 Coated SiC fibers, Al 2 o 3 T...

Embodiment 3

[0025] Add 400g of deionized water into the three-necked flask, heat it to 80°C, and mix the pre-ground 0.8g of Al(OC 3 h 7 ) 3 Add the powder slowly, and stir at 90°C for 2 hours after the addition, so that the Al(OC 3 h 7 ) 3 Complete hydrolysis to form Al(OH) 3 Precipitate, make the C produced by the reaction as much as possible under stirring conditions 3 h 7 OH evaporates completely; then add HNO dropwise 3 , control the pH value of the solution in the range of 3-4 to peptize the precipitate; finally, under reflux and stirring at 90°C, age for 13h to obtain a stable and transparent AlOOH sol.

[0026] Soak uncoated SiC fibers in AlOOH sol for 4 hours, then dry at 90°C for 2 hours, and perform gelation treatment to obtain SiC fibers coated with AlOOH sol; place the above-treated SiC fibers in a tube furnace under nitrogen Under the condition of protection, heating to 600°C and keeping it for 2h, the Al 2 o 3 Coated SiC fibers, Al 2 o 3 The coating thickness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com