PLC cooperative control device based on SOPC technology

A technology of collaborative control and technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as single control, and achieve the effects of increased reliability, strong modifiability, and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

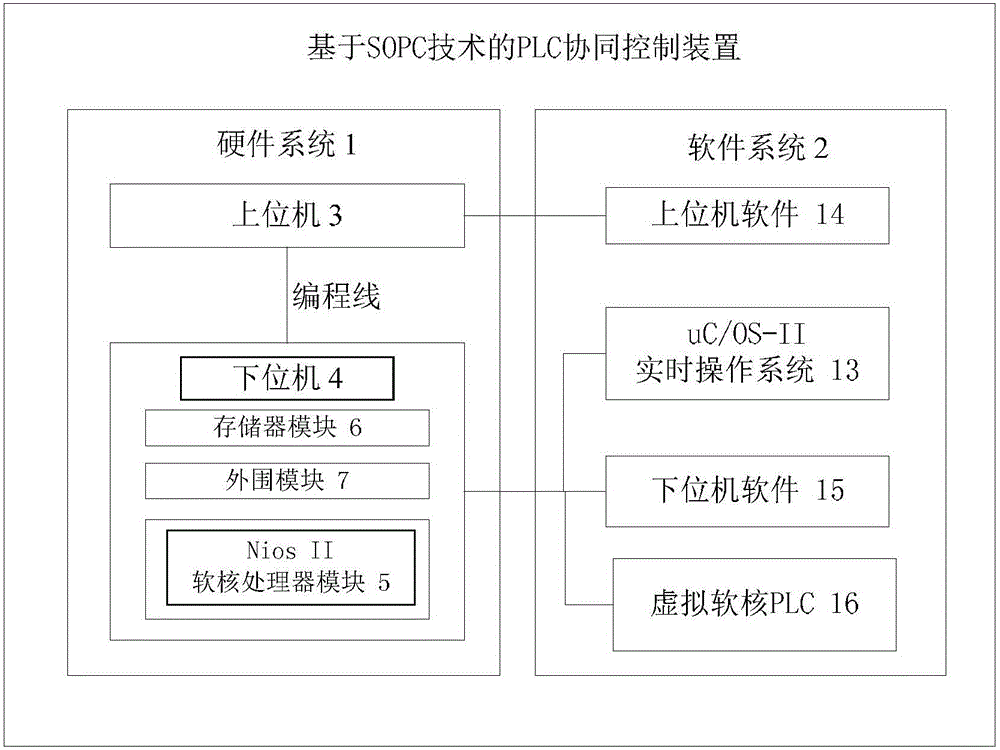

[0024] Such as figure 1 , the PLC cooperative control device based on SOPC technology comprises hardware system 1 and software system 2 two parts; Described hardware system 1 comprises upper computer 3 and lower computer 4; Described lower computer 4 is composed of NiosII soft-core processor module 5, Memory module 6 and peripheral module 7 form, and wherein NiosII soft-core processor module 5 is made up of CPU module 8, TIMER0 module 9, TIMER1 module 10, UART module 11, JTAG module 12; Described software system 2 comprises embedded uC / OS-II real-time operating system 13, upper computer software 14, lower computer software 15, virtual soft-core PLC 16.

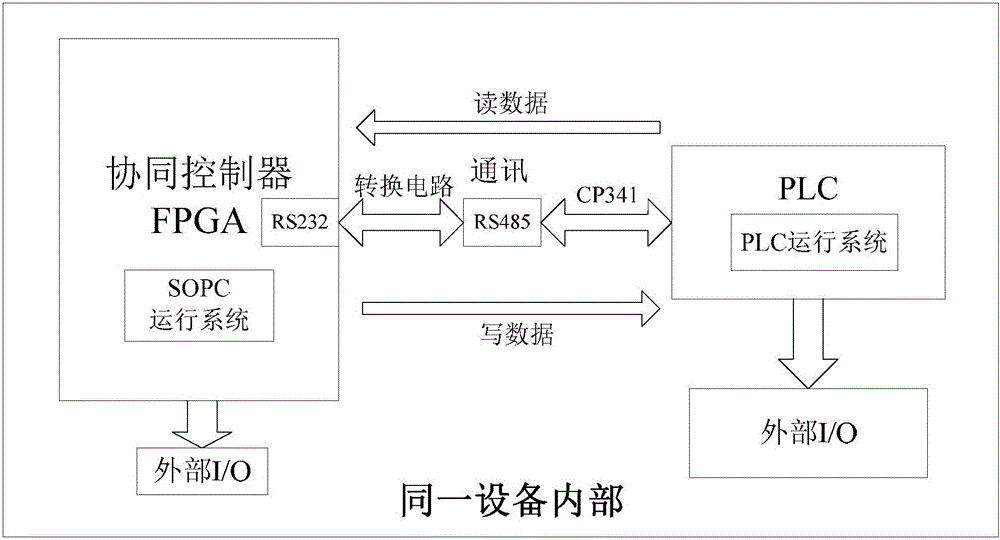

[0025] Such as figure 2 , the PLC cooperative control device based on SOPC technology is to access the internal resources of the PLC through the field bus without changing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com