Dissipative particle dynamics simulation method for grinding liquid particle characteristics

A simulation method and technology of grinding liquid, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems in milliseconds, micron-level space-time scales, limited to nanoseconds, nano-levels, and computational simulation work is not feasible, etc. problem, to improve research and use effect, better control and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The dissipative particle dynamics simulation method of the characteristics of the grinding fluid particles in this embodiment, the specific steps are as follows:

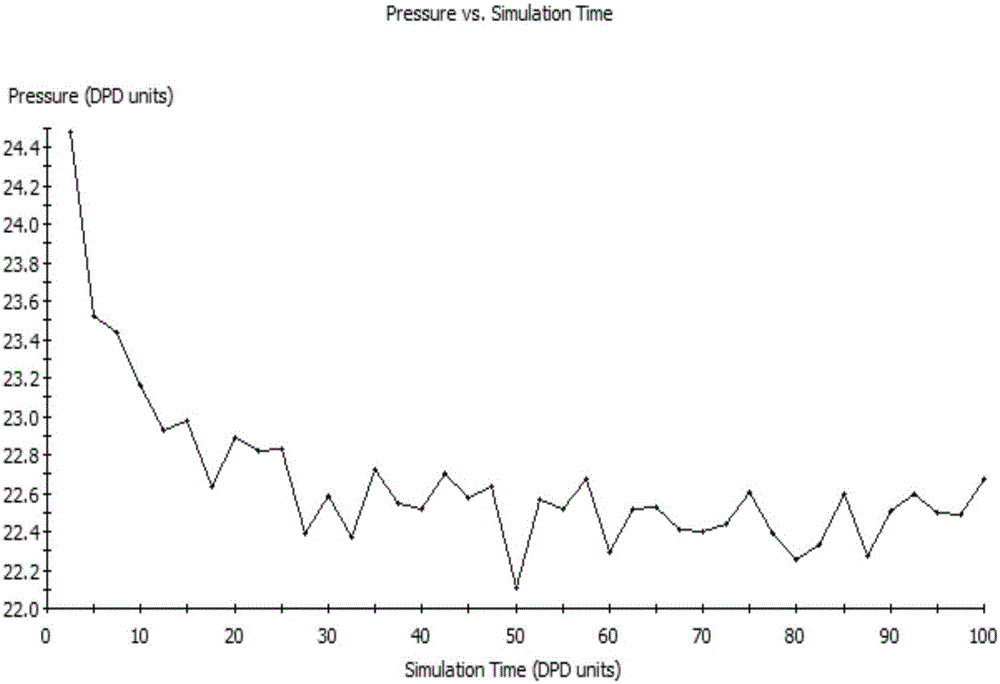

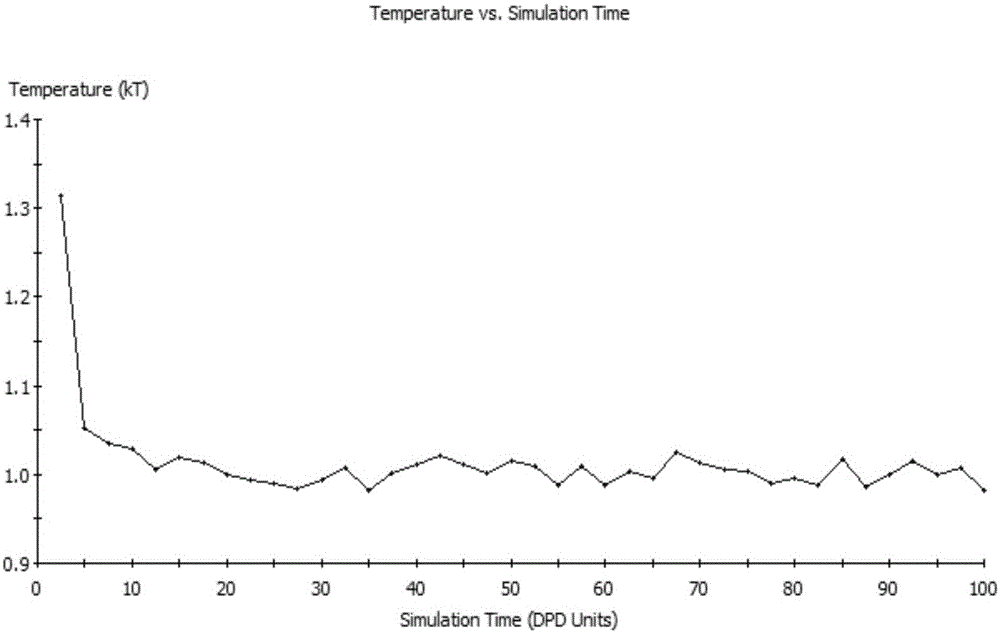

[0015] (1) Analysis and calculation of DPD particles for a single slurry particle: select silicon carbide (SiC) particles in the slurry for analysis, and establish its DPD particle model. In the process of modeling silicon carbide particles, the number of silicon carbide particles is selected within a certain range, and its boundary conditions also need to be redefined. For the composition of silicon carbide atoms, it is composed of one silicon atom and two carbon atoms. The initial The states are in a certain ratio, and certain boundary conditions are selected when the polyatomic composition is carried out. In the computer simulation setting, 100 identical DPD particles are projected into a dimensionless calculation area of 10×10, and the traditional DPD method is used to make the system reach an equilibri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com