Flexible neural microelectrode array with hollow projection structure and manufacturing method thereof

A micro-electrode array, micro-electrode technology, applied in the direction of electrodes, medical science, sensors, etc., can solve the problems of electrodes affecting signal measurement, achieve good contact and reduce mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

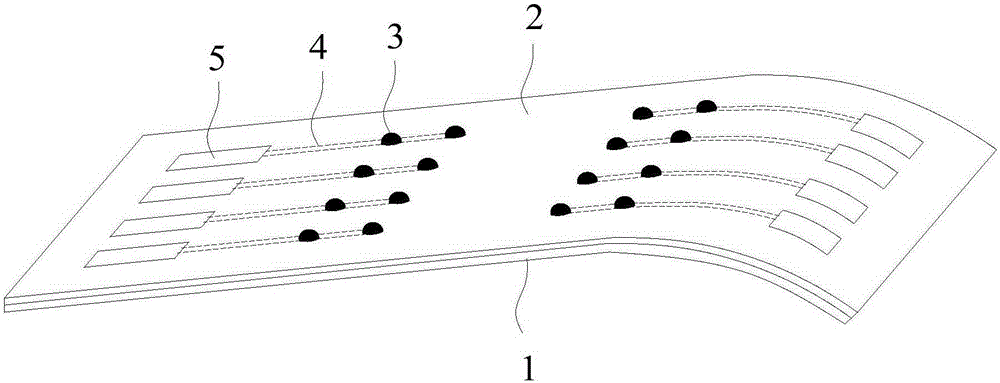

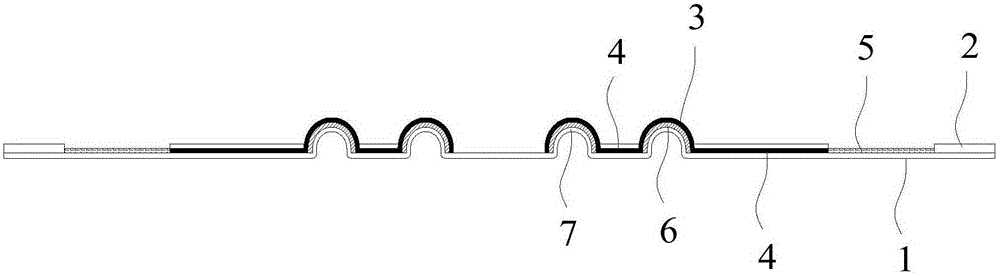

[0028] The present invention provides a flexible nerve microelectrode array (hereinafter referred to as microelectrode array) with a hollow convex structure, referring to figure 1 and figure 2 , figure 1 It is a schematic diagram of the three-dimensional structure of the flexible neural microelectrode array with a hollow convex structure in the present invention, figure 2 It is a cross-sectional view of the side structure of the flexible neural microelectrode array with a hollow raised structure in the present invention. The flexible neural microelectrode array with a hollow raised structure includes a flexible substrate 1, an insulating layer 2, a microelectrode unit 3, a wire 4 and a lead Welding spot 5, described microelectrode unit 3, wire 4 and lead welding spot 5 are arranged on described flexible base 1, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com