Preparation of Attapulgite Capillary Monolithic Column and Its Application in Solid Phase Microextraction

A capillary monolithic column and attapulgite technology, which is applied in the field of chromatographic analysis sample pretreatment, can solve the problems of lack of microporous structure, few action sites, insufficient column capacity, etc., and achieves easy control of reaction conditions, low detection limit, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

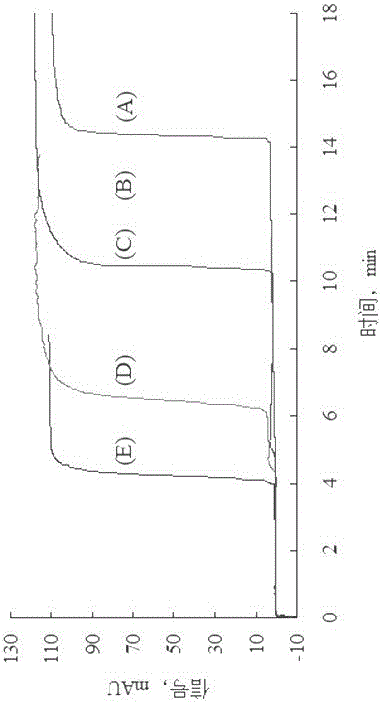

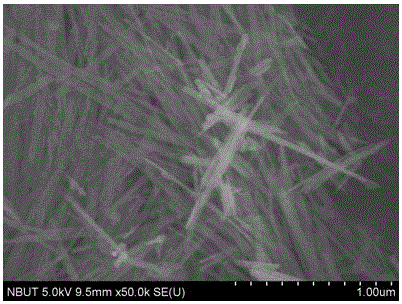

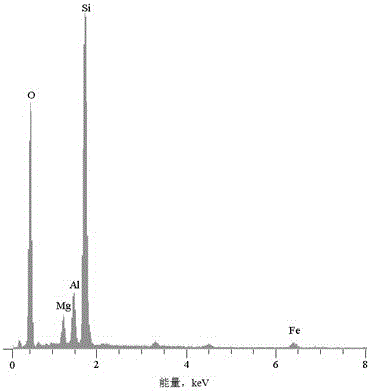

[0027] Example 1: Weigh 2 g of the organic polymer solution prepared in step (3), add 0.1 g of attapulgite treated in step (2), and stir magnetically for 3 h at room temperature to uniformly disperse attapulgite in the organic The polymer solution was degassed with nitrogen for 5 min, injected into the capillary treated in step (1), the two ends of the capillary were plugged tightly with silicone rubber, heated in a constant temperature water bath at 75 °C for 20 h, and then cooled to room temperature to obtain Attapulgite-embedded capillary monolith column with a mass ratio of attapulgite to organic polymer solution of 5%.

Embodiment 2

[0028] Example 2: Weigh 2 g of the organic polymer solution prepared in step (3), add 0.06 g of attapulgite treated in step (2), and stir magnetically for 3 h at room temperature to uniformly disperse attapulgite in the organic The polymer solution was degassed with nitrogen for 5 min, injected into the capillary treated in step (1), the two ends of the capillary were plugged tightly with silicone rubber, heated in a constant temperature water bath at 75 °C for 20 h, and then cooled to room temperature to obtain Attapulgite-embedded capillary monolith column with a mass ratio of attapulgite to organic polymer solution of 3%.

Embodiment 3

[0029]Example 3: Weigh 2 g of the organic polymer solution prepared in step (3), add 0.032 g of the attapulgite treated in step (2), and stir magnetically for 3 h at room temperature to uniformly disperse the attapulgite in the organic The polymer solution was degassed with nitrogen for 5 min, injected into the capillary treated in step (1), the two ends of the capillary were plugged tightly with silicone rubber, heated in a constant temperature water bath at 75 °C for 20 h, and then cooled to room temperature to obtain Attapulgite-embedded capillary monolith column with a mass ratio of attapulgite to organic polymer solution of 1.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com