Method for producing waste mushroom bran organic fertilizer

An organic fertilizer and production method technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of low recycling efficiency of waste fungus chaff, not receiving enough attention, etc., to improve the ability of plants to resist diseases and insect pests, enrich the Contains trace elements and promotes plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

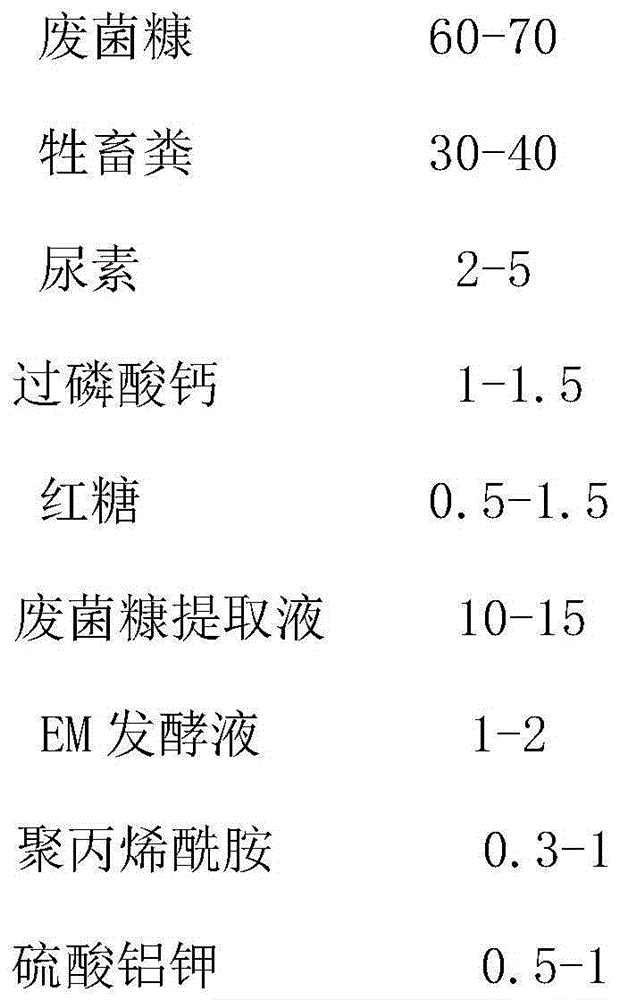

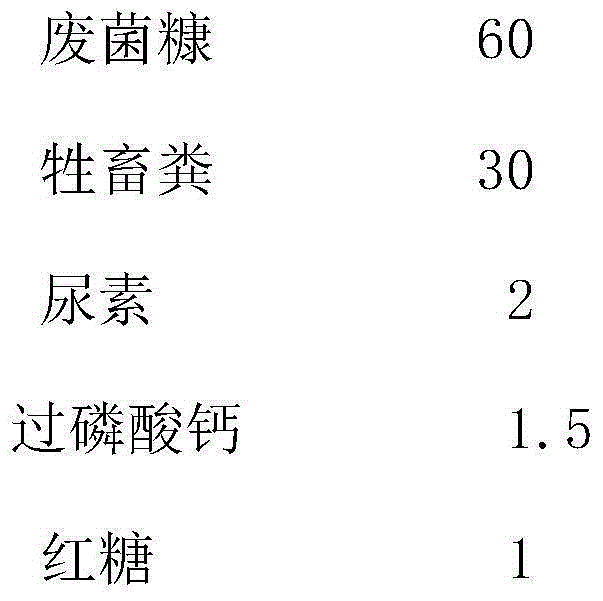

[0028] A production method of waste fungus chaff organic fertilizer, comprising the following steps:

[0029] a. Mix 60 parts of waste fungus chaff, 30 parts of livestock manure, 2 parts of urea, 1.5 parts of superphosphate, and 1 part of brown sugar, and build a heap for fermentation for 3 days; the fermentation temperature is 45°C;

[0030] b. Then, turn the pile, spray 10 parts of the waste fungus chaff extract, and continue to build the pile for fermentation; the fermentation temperature is 65°C, and the fermentation time is 4 days; turn the pile once a day;

[0031] c. Then, spray 1 part of EM fermented liquid on the fermented material in step b, continue to build a heap, ferment for 5 days, and turn the heap once a day.

[0032] d. Mix 0.5 part of polyacrylamide, 0.6 part of aluminum potassium sulfate, 0.5 part of calcium carbonate, 0.5 part of copper sulfate, and 0.5 part of medical stone with the fermented material in step c, and mix well to obtain organic fertilizer o...

Embodiment 2

[0043] A production method of waste fungus chaff organic fertilizer, comprising the following steps:

[0044] a. Mix 65 parts of waste fungus chaff, 35 parts of livestock manure, 3 parts of urea, 1 part of superphosphate, and 1.5 parts of brown sugar, and build a heap for fermentation for 3 days; the fermentation temperature is 67°C;

[0045] b. Then, turn the pile, spray 15 parts of the waste fungus chaff extract, and continue to build the pile for fermentation; the fermentation temperature is 67°C, and the fermentation time is 4 days; turn the pile once a day;

[0046] c. Then, spray 2 parts of EM fermented liquid on the fermented material in step b, continue to pile up, ferment for 7 days, and turn the pile once a day.

[0047] d. Mix 0.6 part of polyacrylamide, 0.6 part of aluminum potassium sulfate, 0.7 part of calcium carbonate, 0.7 part of copper sulfate and 0.7 part of medical stone with the fermented material in step c, and mix well to obtain organic fertilizer of was...

Embodiment 3

[0057] A production method of waste fungus chaff organic fertilizer, comprising the following steps:

[0058] a. Mix 70 parts of waste fungus chaff, 40 parts of livestock manure, 5 parts of urea, 1 part of superphosphate, and 1.5 parts of brown sugar, and build a heap for fermentation for 5 days; the fermentation temperature is 55°C;

[0059] b. Then, turn the pile, spray 15 parts of the waste fungus chaff extract, and continue to build the pile for fermentation; the fermentation temperature is 55°C, and the fermentation time is 4 days; turn the pile once a day;

[0060] c. Then, spray 2 parts of EM fermented liquid on the fermented material in step b, continue to build a heap, ferment for 5 days, and turn the heap once a day.

[0061] d. Mix 0.9 part of polyacrylamide, 1 part of aluminum potassium sulfate, 1 part of calcium carbonate, 1 part of copper sulfate and 1 part of medical stone with the fermented material in step c, and mix well to obtain organic fertilizer of waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com