Method for extracting and preparing solanesol from potato leaf

A technology of potato leaves and solanesol, which is applied in the field of extraction and preparation of solanesol, can solve the problems of small preparation throughput, and achieve the effects of cost reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

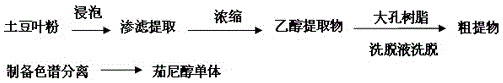

Method used

Image

Examples

Embodiment 1

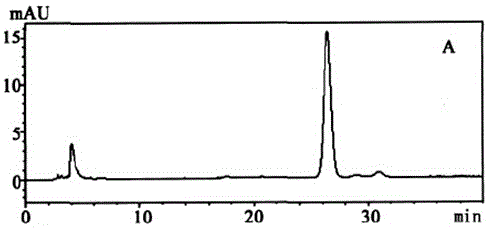

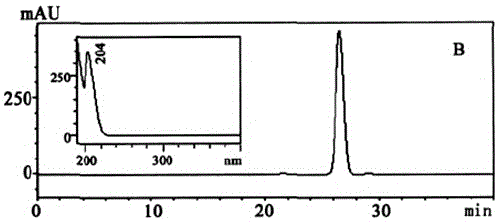

[0024] Crush the potato leaves through a 20-mesh sieve, extract by percolation with an ethanol solution 10 times the weight of the potato leaves for 6 hours, combine the ethanol extracts, recover the ethanol aqueous solution, concentrate until there is no alcohol smell, and obtain the ethanol extract; filter the ethanol extract HZ-801 macroporous resin, eluted with water, 40% ethanol, 60% ethanol, and 80% ethanol in sequence; the eluate after the last step above was eluted with 80% ethanol was collected, and the eluate prepared above Concentrate until there is no alcohol smell, and make a crude extract; the concentrated crude extract prepared above is dissolved in methanol solution successively, filtered through a 0.45 μm microporous membrane, separated by high performance liquid chromatography, and the column Shim-packPREP -ODS chromatographic column (20mm×250mm, 15μm), and then eluted with methanol-ethanol solution with a mobile phase ratio of methanol:ethanol (60:40, V / V) an...

Embodiment 2

[0026] The potato leaves are crushed through a 20-mesh sieve, extracted by percolation with an ethanol solution 5 times the weight of the potato leaves for 9 hours, and the ethanol extracts are combined. Recover the ethanol aqueous solution, concentrate until there is no alcohol smell, and obtain the ethanol extract; pass the ethanol extract through the macroporous resin HZ-801, and then elute with water, 40% ethanol, 60% ethanol, and 80% ethanol. Collect 80% ethanol eluate, and the obtained eluate is concentrated without alcohol smell. The concentrated crude extract was dissolved in methanol solution, filtered through a 0.45 μm microporous membrane, separated by preparative high-performance liquid chromatography, and chromatographic column Shim-packPREP-ODS column (20mm×250mm, 15 μm). The ratio of the mobile phase is: methanol: ethanol (60:40, V / V), the flow rate of the mobile phase is 10 mL / min, the ultraviolet detector is 210 nm for detection, and the injection volume is 30...

Embodiment 3

[0028] The potato leaves are crushed through a 20-mesh sieve, extracted by percolation with an ethanol solution 7 times the weight of the potato leaves for 8 hours, and the ethanol extracts are combined. Recover the ethanol aqueous solution, concentrate until there is no alcohol smell, and obtain the ethanol extract; pass the ethanol extract through the macroporous resin HZ-801, and then elute with water, 40% ethanol, 60% ethanol, and 80% ethanol. Collect 80% ethanol eluate, and the obtained eluate is concentrated without alcohol smell. The concentrated crude extract was dissolved in methanol solution, filtered through a 0.45 μm microporous membrane, separated by preparative high-performance liquid chromatography, and chromatographic column Shim-packPREP-ODS column (20mm×250mm, 15 μm). The ratio of the mobile phase is: methanol: ethanol (60:40, V / V), the flow rate of the mobile phase is 10 mL / min, the ultraviolet detector is 210 nm for detection, and the injection volume is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com