Propylene glycol monostearate, and industrial production method and application thereof

A technology of propylene glycol monostearate and propylene glycol is applied in the field of chemistry to achieve the effects of fine organization, low production cost and easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

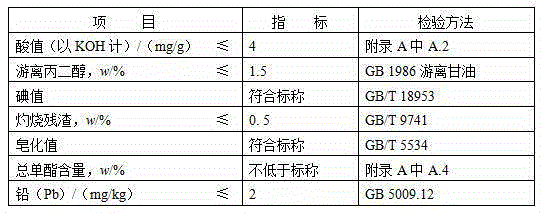

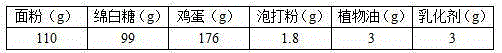

Examples

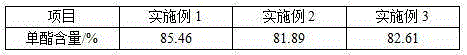

Embodiment 1

[0022] Embodiment 1, propylene glycol monostearate industrial production method of the present invention

[0023] S1, 91.3kg of 1,2-propanediol and 113.8kg of stearic acid are heated and melted respectively and then filtered;

[0024] S2. Pump 1,2-propylene glycol into the reaction kettle, add 0.10% sodium carbonate by weight of 1,2-propylene glycol, stir and mix for 30 minutes, then pump stearic acid into the reaction kettle, control the reaction temperature to 175°C, and the vacuum degree to be 0.07MPa, carry out esterification reaction for 3h;

[0025] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 0.15% phosphoric acid by weight of 1,2-propylene glycol is added, and the neutralization reaction is carried out at 145°C for 0.8h;

[0026] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0027] S5, transfer the crude ester to the distiller for four-stage d...

Embodiment 2

[0028] Embodiment 2, propylene glycol monostearate industrial production method of the present invention

[0029] S1, 60.9kg of 1,2-propanediol and 113.8kg of stearic acid were heated and melted respectively and then filtered;

[0030] S2. Pump 1,2-propanediol into the reactor, add 0.30% sodium bicarbonate by weight of 1,2-propylene glycol, stir and mix for 25 minutes, then pump stearic acid into the reactor, control the reaction temperature to 160°C, vacuum to 0.08MPa, carry out the esterification reaction for 4h;

[0031] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 1,2-propanediol is added with 0.35% phosphoric acid by weight, and the neutralization reaction is carried out at 140 ° C for 1 hour;

[0032] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0033] S5, transfer the crude ester to the distiller for four-stage distillation, wherein the condi...

Embodiment 3

[0034] Embodiment 3, propylene glycol monostearate industrial production method of the present invention

[0035] S1, 121.7kg of 1,2-propanediol and 113.8kg of stearic acid are heated and melted respectively and then filtered;

[0036] S2. Pump 1,2-propanediol into the reactor, add 0.20% sodium hydroxide by weight of 1,2-propylene glycol, stir and mix for 35 minutes, then pump stearic acid into the reactor, control the reaction temperature to 180°C, vacuum 0.06MPa, carry out the esterification reaction for 2h;

[0037] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 0.25% phosphoric acid by weight of 1,2-propylene glycol is added, and the neutralization reaction is carried out at 150°C for 0.5h;

[0038] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0039] S5, transfer the crude ester to a distiller for four-stage distillation, wherein the conditions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com