Dimethylglyoxime magnesium and preparation method thereof

A technology of dimethylglyoxime and magnesium salt, applied in oxime preparation, organic chemistry, etc., can solve the problems of easy damage to turbofan, low melting point, failure, etc., and achieve the effect of improving catalytic effect and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of Dimethylglyoxime Magnesium Compound

[0019] (1) Weigh 34.75g (0.3mol) of dimethylglyoxime, disperse it in 250mL deionized water, adjust the pH value of the solution to 9 with sodium hydroxide solution; weigh 76.8g (0.3mol) magnesium nitrate trihydrate Dissolve with 100mL deionized water to make a solution, add it to the above solution, stir and mix evenly;

[0020] (2) Stir and react for 2 hours at a constant temperature of 70°C, then cool and stand still;

[0021] (3) The precipitate was washed several times with deionized water, filtered, and dried to obtain 47.2 g of a white dimethylglyoxime magnesium compound with a yield of 90.4%.

[0022] Characterization of Dimethylglyoxime Magnesium Compound

[0023] 1. Infrared spectrum (KBr, cm -1 )υ: 3208, 2930, 1939, 1636, 1445, 1384, 1364, 1141, 981, 906.

[0024] 2. Analysis of organic elements

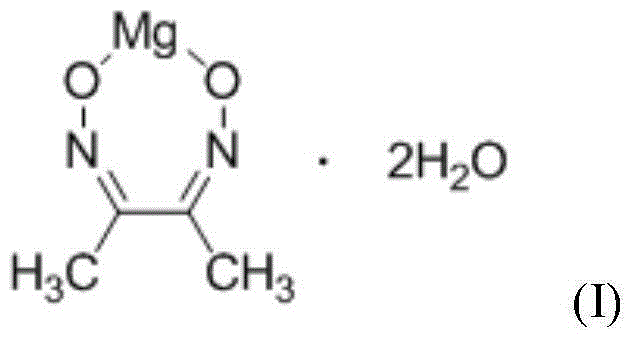

[0025] Molecular formula: C 4 h 6 N 2 o 2 Mg 2H 2 o

[0026] Theoretical value (%): C27.5...

Embodiment 2

[0032] Example 2 Preparation of Dimethylglyoxime Magnesium Compound

[0033] (1) Weigh 1.38g (0.012mol) of dimethylglyoxime, disperse it in 10mL of deionized water, adjust the pH of the solution to 9 with sodium hydroxide solution; weigh 3.07g (0.012mol) of magnesium nitrate trihydrate Dissolve with 10mL deionized water to form a solution, add it to the above solution, stir and mix evenly;

[0034] (2) Stir and react for 2 hours at a constant temperature of 70°C, then cool and stand still;

[0035] (3) The precipitate was washed several times with deionized water, filtered and dried to obtain 1.69 g of white dimethylglyoxime magnesium compound with a yield of 80.9%.

[0036] Analysis of the Solid Phase Decomposition Products of Dimethylglyoxime Magnesium Compound

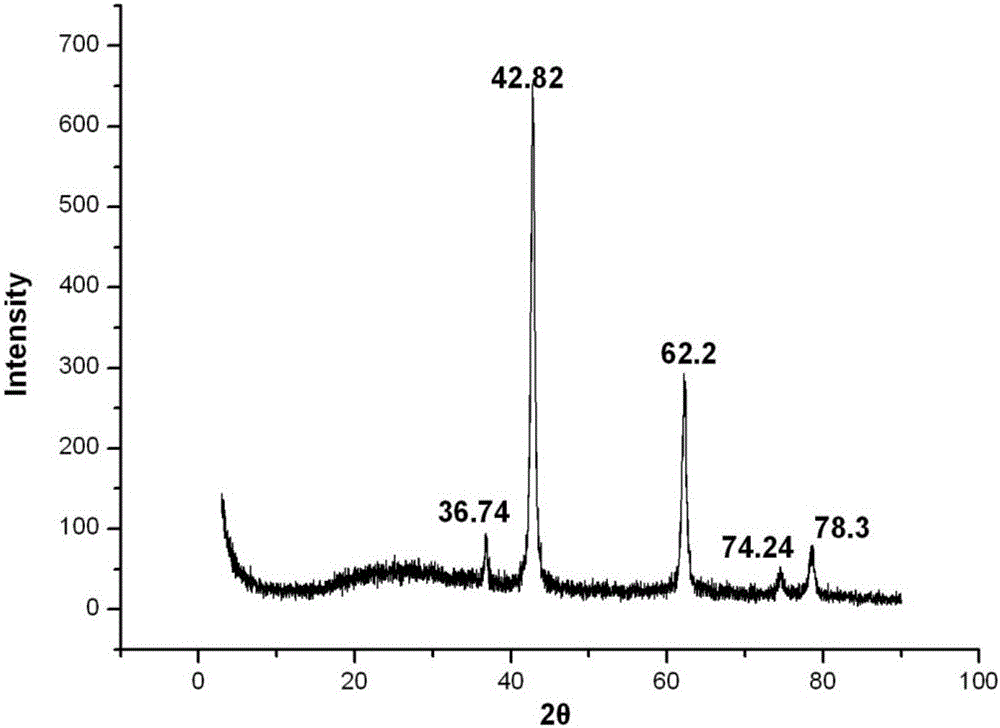

[0037] Dimethylglyoxime magnesium dihydrate was calcined in a crucible at 500°C for 1 hour to obtain a white powder. X-ray diffraction showed that (as figure 1 shown), the five diffraction peaks 36.74, 42.82, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com