Method for extracting tobacco oil component through ultrasonic assisted Soxhlet extraction method

A Soxhlet extraction method and ultrasonic-assisted technology, which is applied in the field of tobacco component extraction, can solve the problems such as ineffective effects, and achieve the effects of less solvent consumption, improved oil extraction rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In order to further understand the present invention, the above-mentioned technical solutions will be further elaborated and described below in conjunction with specific implementation modes.

[0029] See Table 1 and Table 2 for the specific conditions of the reagents and equipment used in the following examples.

[0030] name purity manufacturer Dichloromethane Analytical Pure (AR) Tianjin Fengchuan Chemical Reagent Technology Co., Ltd. Anhydrous Sodium Sulfate Analytical Pure (AR) Tianjin Yaohua Chemical Reagent Co., Ltd. Sodium chloride Analytical Pure (AR) Tianjin Kemiou Chemical Reagent Co., Ltd.

[0031] name manufacturer RE-2000B rotary evaporator Gongyi Yuhua Instrument Co., Ltd. SHZ-D(Ⅲ) circulating water vacuum pump Henan Yuhua Instrument Co., Ltd. FW-400A inclined high-speed universal pulverizer Beijing Zhongxing Weiye Instrument Co., Ltd. electronic analytical balance Beijing...

Embodiment 2

[0064] Repeat the specific extraction steps of tobacco oil in Example 1 to extract four different tobacco samples from Pingdingshan C032, Fujian Nanping C015, Luoyang Luoning C3F and Zambia ZM-BOAT, and use GC / MS instrument to detect the components of the extracts. The components detected in four different samples were compared and analyzed.

[0065] GC / MS combined instrument and detection conditions

[0066] The gas chromatography conditions are:

[0067] Chromatographic column: HP-5MS (30m×0.25mm×0.25μm)

[0068] Programmed temperature rise: keep at 60°C for 5 minutes, raise to 135°C at a rate of 4°C / min; rise to 175°C at a rate of 1°C / min; then raise to 310°C at a rate of 10°C / min, and hold for 10 minutes.

[0069] Injection port temperature: 250°C, injection volume 1μL; carrier gas is high-purity He, carrier gas flow rate 1ml / min; solvent delay 6min; split ratio 10:1

[0070] Mass spectrometry detection conditions:

example 2

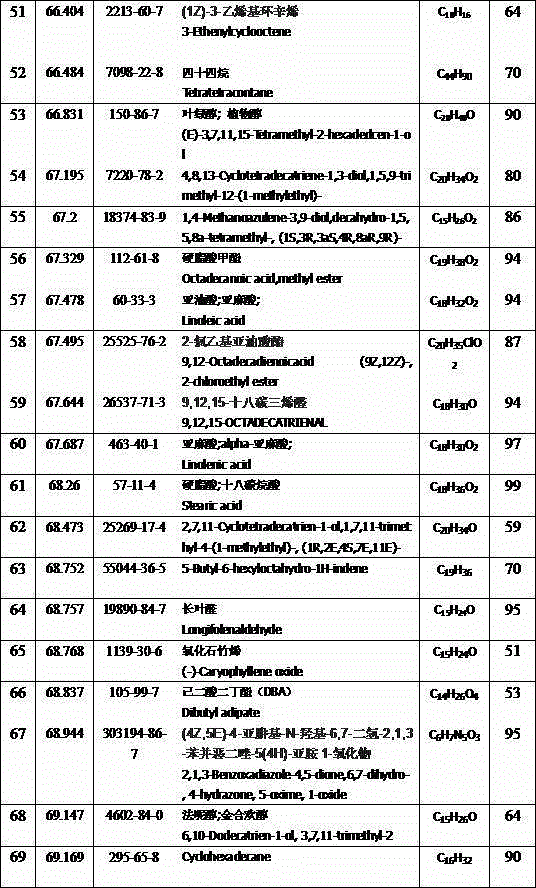

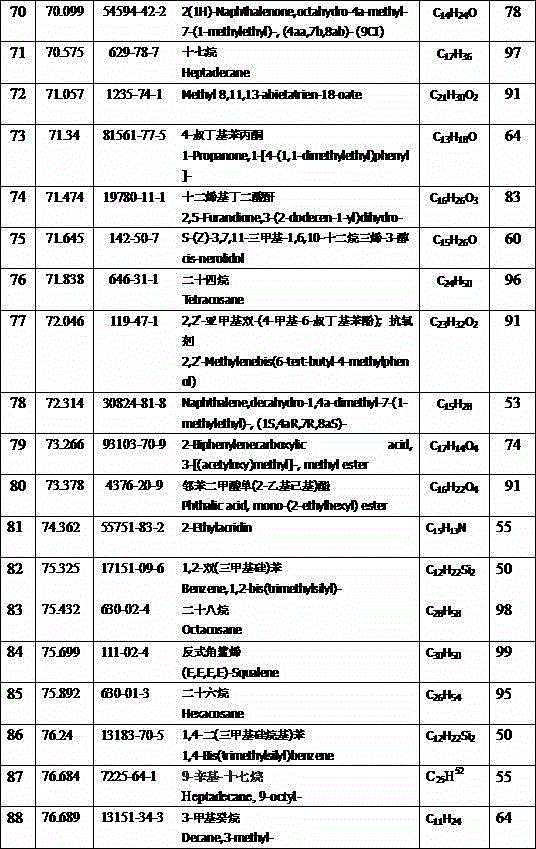

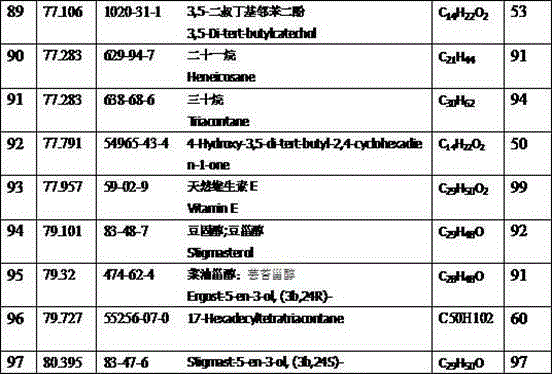

[0073] Table 3 Composition of oil in tobacco

[0074]

[0075] Continued Table 3 Composition of Oil in Tobacco

[0076]

[0077] Continued Table 3 Composition of Oil in Tobacco

[0078]

[0079] Continued Table 3 Composition of Oil in Tobacco

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com