Er/Yb co-doped fiber for improving 1.5 mum laser efficiency

An optical fiber and high-efficiency technology, which is applied in the direction of multi-layer core/cladding optical fiber, cladding optical fiber, microstructure optical fiber, etc., can solve the problems of increasing laser output power, achieve suppression of parasitic oscillation, wide practicability, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0034] The technical indicators and basic performance parameters are as follows:

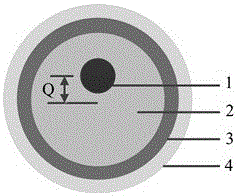

[0035] 1. Central axis offset .

[0036] 2. The diameter of the fiber core is 30 μm, the effective refractive index is 1.538, and the numerical aperture (NA) is 0.08.

[0037] 3. The diameter of the inner cladding is 400 μm, the effective refractive index is 1.536, and the numerical aperture (NA) is 0.4.

[0038] 4. The diameter of the outer cladding is 550 μm.

[0039] 5. The diameter of the coating layer is 700 μm.

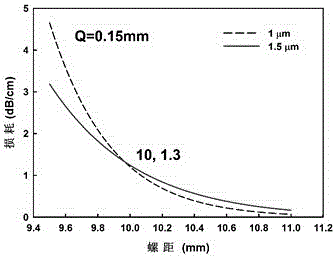

[0040] At this time, the bending loss of the fiber at 1 μm and 1.5 μm varies with the pitch The theoretical simulation diagram of the change is shown in image 3 As shown, it can be clearly seen that when When , the fiber loss in the 1 μm band is greater than that in the 1.5 μm band, which can effectively suppress the parasitic oscillation in the 1 μm band.

Embodiment example 2

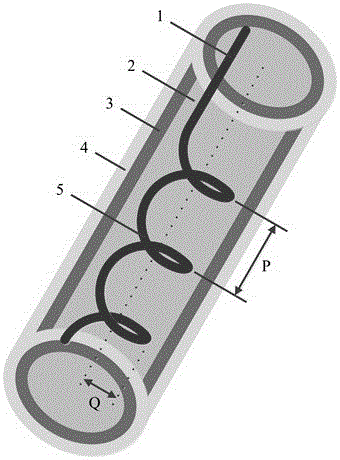

[0042] The structure of the spiral core fiber is as figure 1 and figure 2 shown, the center axis offset , at this time, the bending loss of the fiber at 1 μm and 1.5 μm varies with the pitch The theoretical simulation diagram of the change is shown in Figure 4 As shown, it can be clearly seen that when When , the fiber loss in the 1 μm band is greater than that in the 1.5 μm band, which can effectively suppress the parasitic oscillation in the 1 μm band.

Embodiment example 3

[0044] The structure of the spiral core fiber is as figure 1 and figure 2 shown, the center axis offset , at this time, the bending loss of the fiber at 1 μm and 1.5 μm varies with the pitch The theoretical simulation diagram of the change is shown in Figure 4 As shown, it can be clearly seen that when When , the fiber loss in the 1 μm band is greater than that in the 1.5 μm band, which can effectively suppress the parasitic oscillation in the 1 μm band.

[0045] In summary, the present invention proposes an Er, Yb co-doped spiral core fiber, by adjusting the central axis offset Q and pitch P , can change the fiber loss corresponding to different wavelengths, so that the fiber loss in the 1μm band is greater than the fiber loss in the 1.5μm band, and achieve the effect of suppressing 1μm parasitic oscillation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com