Perylene-3,4,9,10-tetracarboxylic acid dianhydride organic layer optoelectronic coupler and manufacture method

A technology of perylene tetracarboxylic dianhydride and coupler is applied in the field of new semiconductor optoelectronic devices in microelectronics and optoelectronics, which can solve the problems of low photoelectric conversion efficiency of silicon photodiodes and phototransistors, circuit operation stability and reliability. Problems such as narrow linear working range, to achieve good stability and reliability, improve stability and reliability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

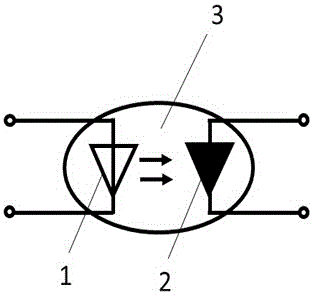

[0054] Product examples such as figure 1 Shown: a perylenetetracarboxylic dianhydride organic layer optical coupler, including a light emitter and a light receiver assembled in the same sealed metal shell 3, the light emitter is a GaAs infrared light-emitting diode chip 1, and the light receiver is perylenetetracarboxylic acid Dihydride photodetector electrode chip 2 . The metal shell 3 is a metal tube shell with an open top, and the highly transparent epoxy resin is injected into the metal tube shell to completely insulate and encapsulate the two chips electrically.

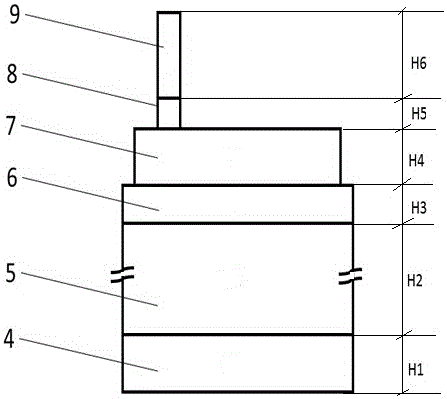

[0055] see figure 2 : perylenetetracarboxylic dianhydride photodetector electrode chip, including sequentially laminated gold electrode layer 4, P-Si substrate layer 5, perylenetetracarboxylic dianhydride single crystal film layer 6 and ITO film layer 7, the surface of the ITO film layer 7 A nickel film layer 8 is provided, and an aluminum film layer 9 is provided on the surface of the nickel film layer 8; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com