LED epitaxial structure having combination barrier multi-quantum well and preparation method

A multi-quantum well structure and multi-quantum well technology, which is applied in the field of high-brightness LED epitaxial structure and its preparation, can solve the problems of large stress and low quantum efficiency, and achieve the effects of reducing stress, improving device performance, and alleviating bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

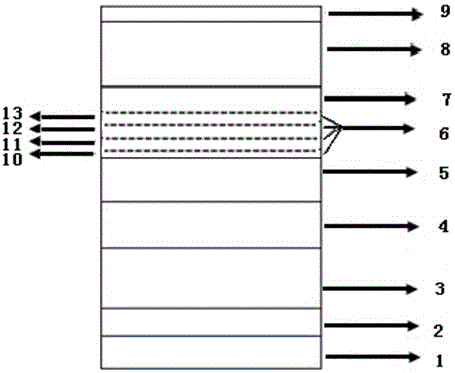

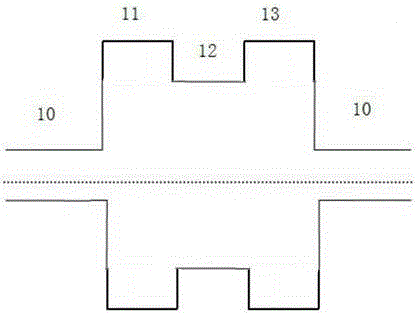

[0043] Such as figure 1 As shown, the present invention has a high-brightness base LED epitaxial structure with combined potential barriers and multiple quantum wells, and is provided with a substrate layer 1, a GaN buffer layer 2, an undoped GaN layer 3, an n-type AlGaN layer 4, and an n-type AlGaN layer from bottom to top. Type GaN layer 5, multi-quantum well active light-emitting layer 6, P-type AlGaN layer 7, P-type GaN layer 8 and P-type InGaN ohmic contact layer 9. The substrate is sapphire. The thickness of the GaN buffer layer is 20-40nm. The thickness of the non-doped GaN layer is 2-3 μm. The thickness of the n-type AlGaN layer is 30-60 nm. The thickness of the n-type GaN layer is 2-3 μm. The thickness of the P-type AlGaN layer is 50-100 nm. The thickness of the P-type layer is 150-300nm. The thickness of the P-type ohmic contact layer is 2-10 nm. The multi-quantum well active light-emitting layer 6 is a combined barrier. The multi-quantum well layer is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com