Sweetener composition, method for manufacturing same and use thereof

A manufacturing method and a technology for a composition, applied in the field of body, can solve the problems of difficulty in refining, significant coloring of the product, disproportionate industrial production efficiency, etc., and achieve excellent effects in terms of sweetness and physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

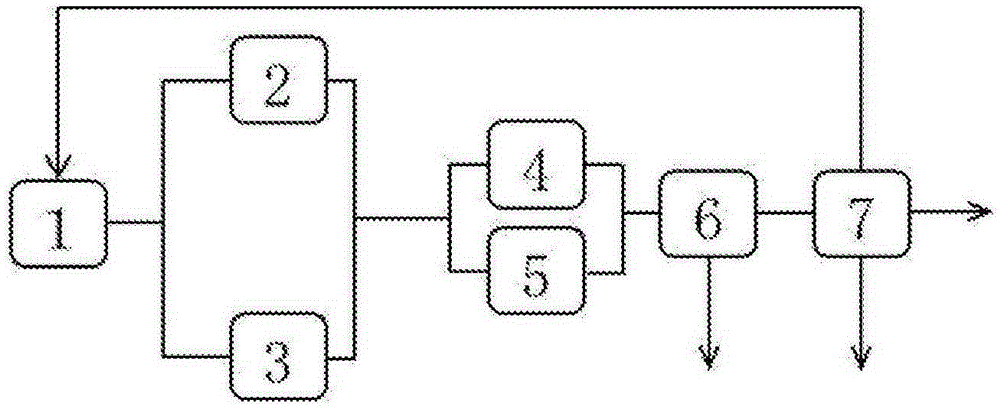

Image

Examples

experiment example A

[0139]

[0140] Using sugar and hydrochloric acid, a 0.7 mol / l hydrochloric acid solution containing 3% (w / v) of sugar was prepared. This was hydrolyzed at a temperature of 40° C. for 20 minutes, 30 minutes, 50 minutes, and 80 minutes, respectively. After neutralizing the decomposed solution with sodium hydroxide, it was analyzed by HPLC (detector: RI, column: Mitsubishi Chemical Corporation MCIGELCK08EC, mobile phase: water, flow rate: 0.4ml / min) (this analysis condition is also used in the following experimental examples) same.).

[0141] The sugar composition (%) of the obtained hydrolyzate is shown in Table 1 below.

[0142] [Table 1]

[0143]

[0144] Next, in order to confirm whether the sugar composition obtained by acid hydrolysis is similarly decomposed at different concentrations, the sugar composition under acid hydrolysis conditions at 90°C was confirmed for a 80% (w / w) solution of granulated sugar, and it was confirmed that break down.

[0145] In addition,...

experiment example B~D

[0146]

[0147] Using sugar and invertase (manufactured by MPBiomeicals, Inc., 100 unit / mg), a 3% (w / v) sugar solution containing invertase (0.003% w / w, sugar g) was prepared. This was hydrolyzed at a temperature of 40° C. for 20 minutes, 30 minutes, and 40 minutes, respectively, and HPLC analysis was performed in the same manner as in Example 1.

[0148] The sugar composition (%) of the obtained hydrolyzate is shown in Table 2 below.

[0149] [Table 2]

[0150]

[0151] Next, a 25% (w / v) sucrose solution containing invertase (0.00075% w / w, saccharose g) was prepared and subjected to 10 minutes, 20 minutes, 30 minutes, 40 minutes, and 50 minutes at a temperature of 40°C. , 60 minutes, 70 minutes, and 80 minutes of hydrolysis, HPLC analysis was performed in the same manner.

[0152] The sugar composition (%) of the obtained hydrolyzate is shown in Table 3 below.

[0153] [table 3]

[0154]

[0155] Further, commercially available invertase (manufactured by DSM, 200 ...

experiment example E

[0161]

[0162] Each solution of the enzymatic hydrolyzate obtained in the experimental areas C3, C4, and C5 in Experimental Example 2 was prepared to 0.1M NaOH, and the isomerization reaction was performed at a temperature of 60° C. for 2 hours. A part of the reaction liquid after the isomerization reaction was sampled, and the sugar composition was analyzed by HPLC.

[0163] The sugar composition of the obtained alkali isomerization reaction product is shown in Table 5 below.

[0164] [table 5]

[0165]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com