A kind of marine biological inhibitor of seawater once-through cooling system and preparation method thereof

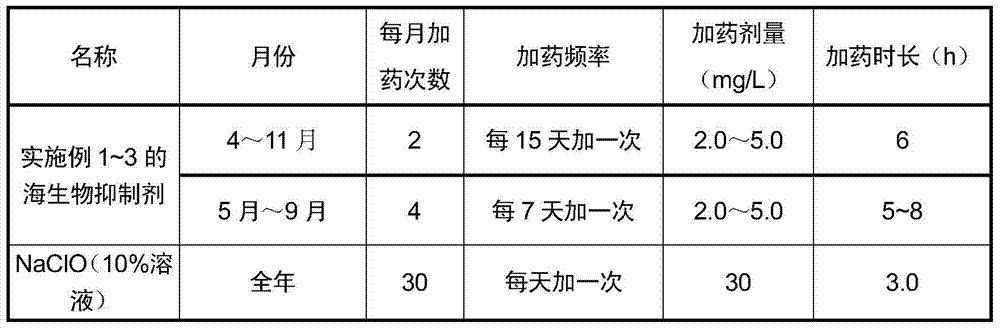

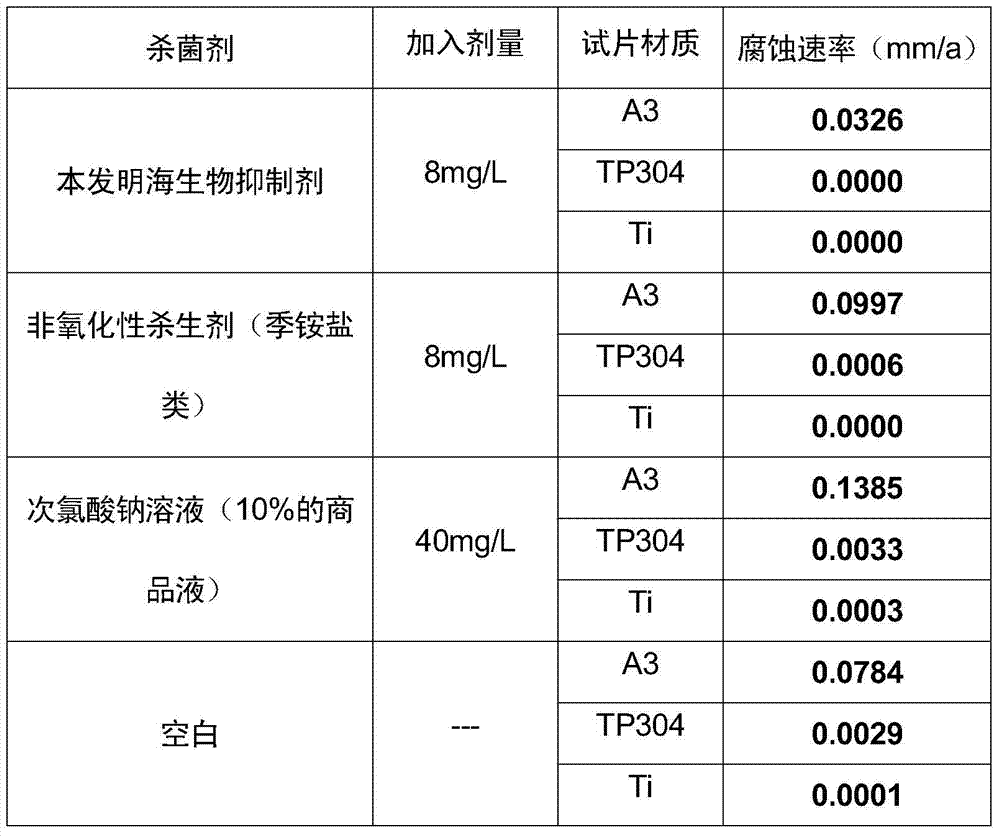

A once-through cooling, marine biological technology, applied in the fields of botanical equipment and methods, biocides, chemicals for biological control, etc. Achieve strong killing efficiency, keep clean and efficient operation, and slow down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

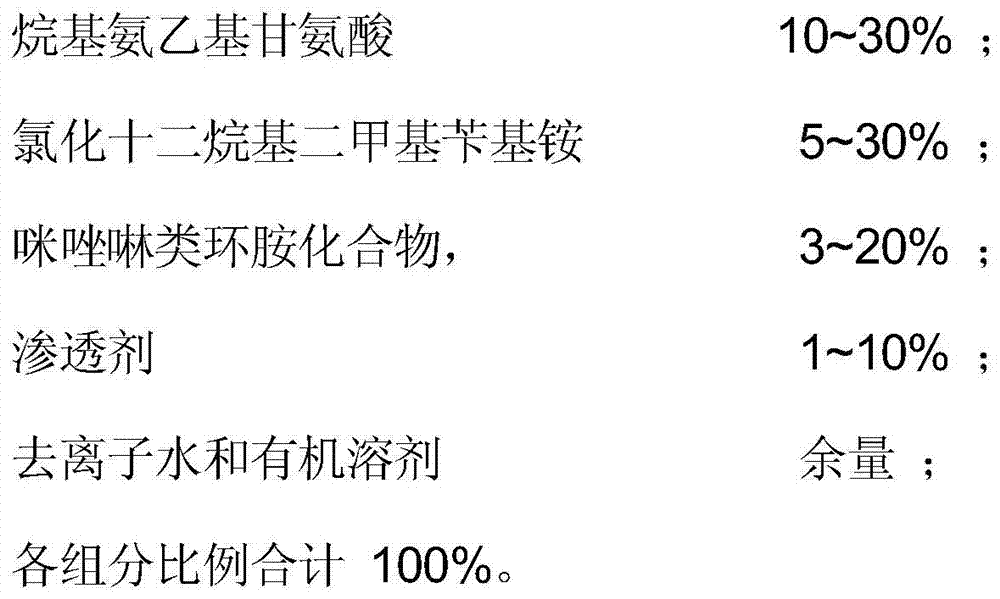

Method used

Image

Examples

Embodiment 1

[0029] Put 10% by weight of 2,5-pentylamine-benzimidazole, 20% by weight of organic solvent, and 5% by weight of deionized water into the reactor successively, and stir and raise the temperature at a speed of 50~70rpm Fully dissolve at 60°C to form a stable mixture A; 15% by weight of dodecyl dimethyl benzyl ammonium chloride, 5% by weight of penetrant and 15% by weight of deionized water are added to the reaction Stir and dissolve in the container to form a stable mixture B; after adding the mixture B into the reaction kettle and mixing the mixture A fully for dissolution, slowly adding 30% by weight of the alkylaminoethylglycine solution and stirring uniformly to obtain the copolymer product. Discharge into barrels. Among them: the penetrant is dodecyl fatty alcohol polyoxyethylene ether JFC, and the organic solvent is ethanol.

Embodiment 2

[0031] Put 8% by weight of 2,5-pentylamine-benzimidazole, 23% by weight of organic solvent, and 5% by weight of deionized water into the reactor successively, and stir and raise the temperature at a speed of 50~70rpm Fully dissolve at 60°C to form a stable mixture A; 20% by weight of dodecyl dimethyl benzyl ammonium chloride, 4% by weight of penetrant and 15% by weight of deionized water are added to the reaction Stir and dissolve in the container to form a stable mixture B; after adding the mixture B into the reactor and fully stirring and dissolving the mixture A, slowly add 25% by weight of the alkylaminoethylglycine solution and stir uniformly to obtain the copolymer product. Discharge into barrels. Among them: the penetrant is myristyl fatty alcohol polyoxyethylene ether, and the organic solvent is isopropanol.

Embodiment 3

[0033] Put 10% by weight of 2,5-pentylamine-benzimidazole, 20% by weight of organic solvent, and 5% by weight of deionized water into the reactor successively, and stir and raise the temperature at a speed of 50~70rpm Fully dissolve at 60°C to form a stable mixture A; 30% by weight of dodecyldimethylbenzylammonium chloride, 6% by weight of penetrant and 15% by weight of deionized water are added to the reaction Stir and dissolve in the container to form a stable mixture B; after adding the mixture B into the reactor and fully stirring and dissolving the mixture A, slowly add 19% by weight of the alkylaminoethylglycine solution and stir uniformly to obtain the copolymer product. Discharge into barrels. Among them: the penetrant is stearyl fatty alcohol polyoxyethylene ether, and the organic solvent is cyclohexanone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com