Superfine-pore hydrogel bracket and preparation method therefor

A pore water and gel technology, applied in the field of artificial skin, can solve the problems of natural polymer mechanical properties and processing properties that need to be studied and improved, and achieve the effects of good water vapor transmission rate, simple operation and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

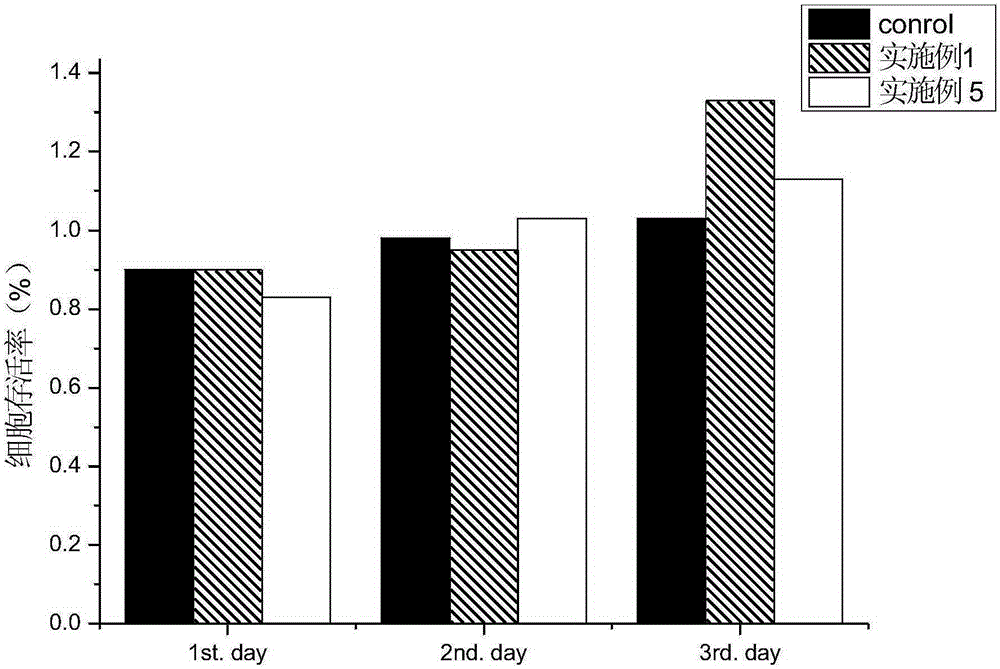

Examples

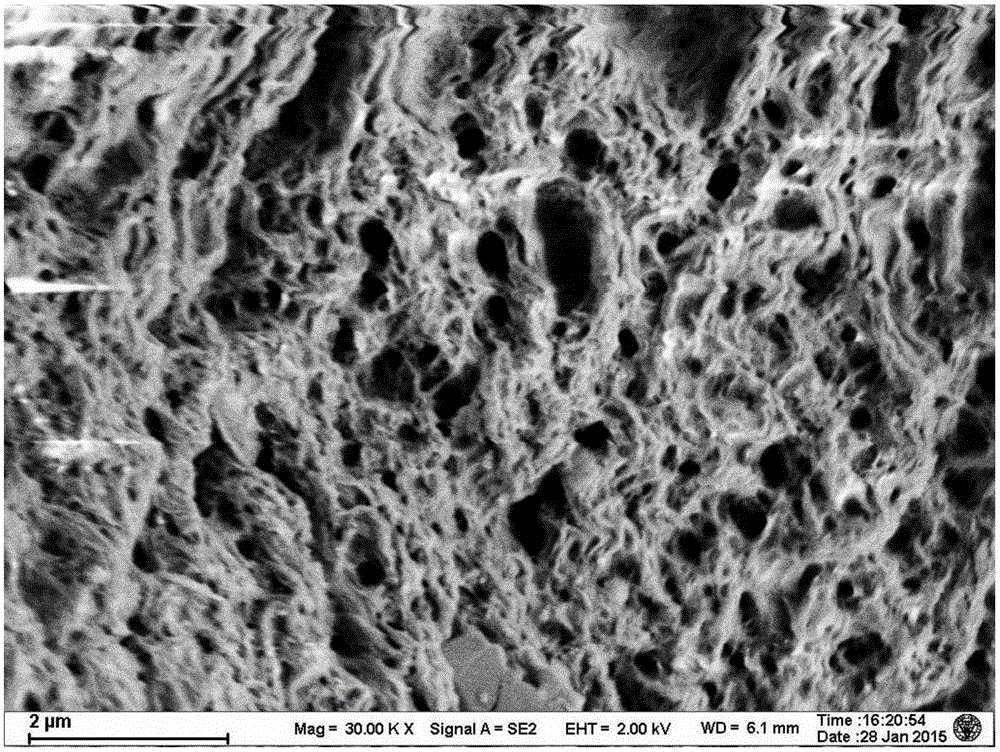

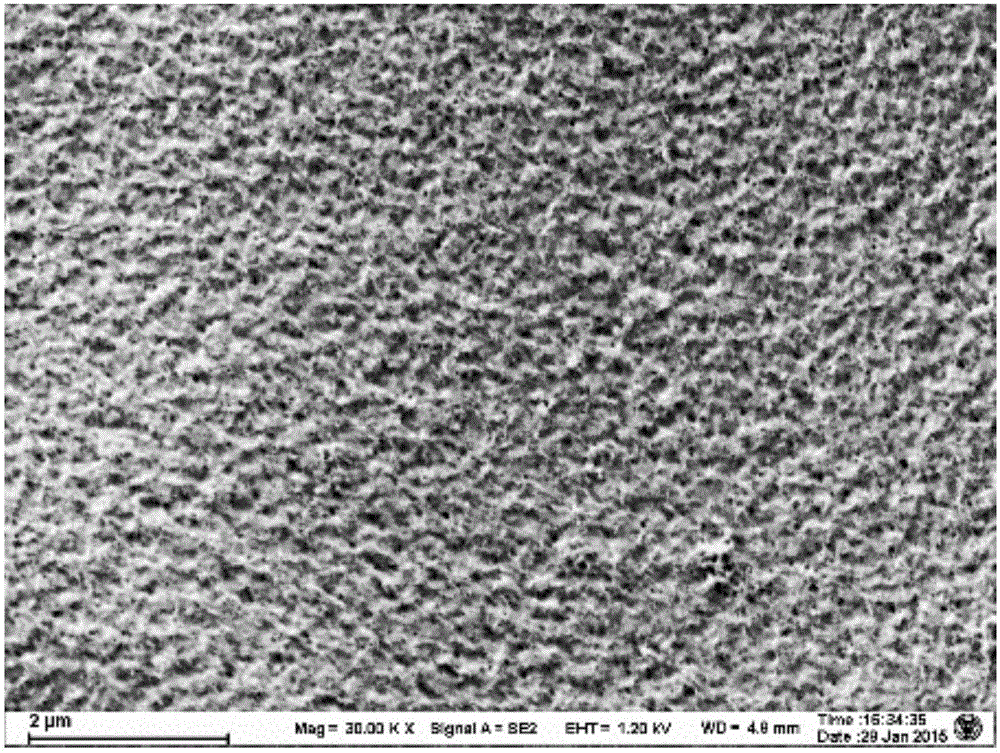

Embodiment 1

[0017] Weigh 1g of sodium alginate and dissolve it in 100mL of aqueous solution, add it to a 250mL beaker, seal the mouth of the beaker with wax film, and completely dissolve it to a transparent and clear solution at a speed of 500r / min and a temperature of 28℃ to make 0.01g / mL of sodium alginate solution; weigh 2gCaCl 2 Dissolve in 100mL water solution to prepare 0.02g / mL CaCl 2 Aqueous solution; CaCl 2 The aqueous solution and DMSO are mixed at a volume ratio of 1:1 to form CaCl 2 Mixed solution of aqueous solution and DMSO. Add 3 mL of sodium alginate solution to a petri dish with a diameter of 10 cm, make the sodium alginate solution evenly cover the bottom of the petri dish, let it stand for 10 minutes, and use a disposable dropper to quickly and evenly drop CaCl 2 The mixed solution of the solution and DMSO was 3 mL, and the petri dish was quickly put into a low-pressure vacuum drying box, and dried at -0.1 mPa for 10 minutes, and then a completely cross-linked skin cell s...

Embodiment 2

[0019] Weigh 3g of sodium alginate and dissolve it in 100mL of aqueous solution, add it to a 250mL beaker, seal the mouth of the beaker with wax film, and use a rotation speed of 500r / min and a temperature of 28℃ to completely dissolve it to a clear and clear solution to make 0.03g / mL of sodium alginate solution, weigh 2gCaCl 2 Dissolve in 100mL water solution to prepare 0.02g / mL CaCl 2 Aqueous solution, CaCl 2 The aqueous solution and DMSO are mixed at a volume ratio of 1:1 to form CaCl 2 Mixed solution of aqueous solution and DMSO. Add 3 mL of sodium alginate solution to a petri dish with a diameter of 10 cm, make the sodium alginate solution evenly cover the bottom of the petri dish, let it stand for 10 minutes, and use a disposable dropper to quickly and evenly drop CaCl 2 The mixed solution of the solution and DMSO was 3 mL, and the petri dish was quickly put into a low-pressure vacuum drying box, and dried at -0.1 mPa for 10 minutes, and then a completely cross-linked skin...

Embodiment 3

[0021] Weigh 1g of sodium alginate and dissolve it in 100mL of aqueous solution, add it to a 250mL beaker, seal the mouth of the beaker with wax film, and use a rotation speed of 500r / min and a temperature of 28℃ to completely dissolve to a transparent clear solution to make 0.01g / mL of sodium alginate solution, weigh 2gCaCl 2 Dissolve in 100mL water solution to prepare 0.02g / mL CaCl 2 Aqueous solution, CaCl 2 The aqueous solution and DMSO are mixed at a volume ratio of 2:1 to form CaCl 2 Mixed solution of aqueous solution and DMSO. Add 3 mL of sodium alginate solution to a petri dish with a diameter of 10 cm, make the sodium alginate solution evenly cover the bottom of the petri dish, let it stand for 10 minutes, and use a disposable dropper to quickly and evenly drop CaCl 2 The mixed solution of the solution and DMSO was 3 mL, and the petri dish was quickly put into a low-pressure vacuum drying box, and dried at -0.1 mPa for 10 minutes, and then a completely cross-linked skin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com