Preparation method for sulfonated cobalt phthalocyanine sensitized titanium dioxide compound photocatalyst

A sulfonated cobalt phthalocyanine sensitized titanium dioxide, sulfonated cobalt phthalocyanine technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of large consumption Organic solvents, difficult mass production, and high preparation costs, to achieve the effects of low cost, stable performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, the purpose of which is only to better understand the content of the present invention and not to limit the protection scope of the present invention.

[0025] Sensitizer activation: Take 500mg of industrial sulfonated cobalt phthalocyanine, add 100mL of 0.5M sodium hydroxide aqueous solution, ultrasonic for 5 minutes to promote dissolution, filter to remove insoluble impurities, and then add 1.0M hydrochloric acid to the filtrate to adjust The pH value is 2-3, which is acidified and precipitated, filtered and dried to obtain 330 mg of activated cobalt sulfonate phthalocyanine. The yield of the purification and activation step is about 66%.

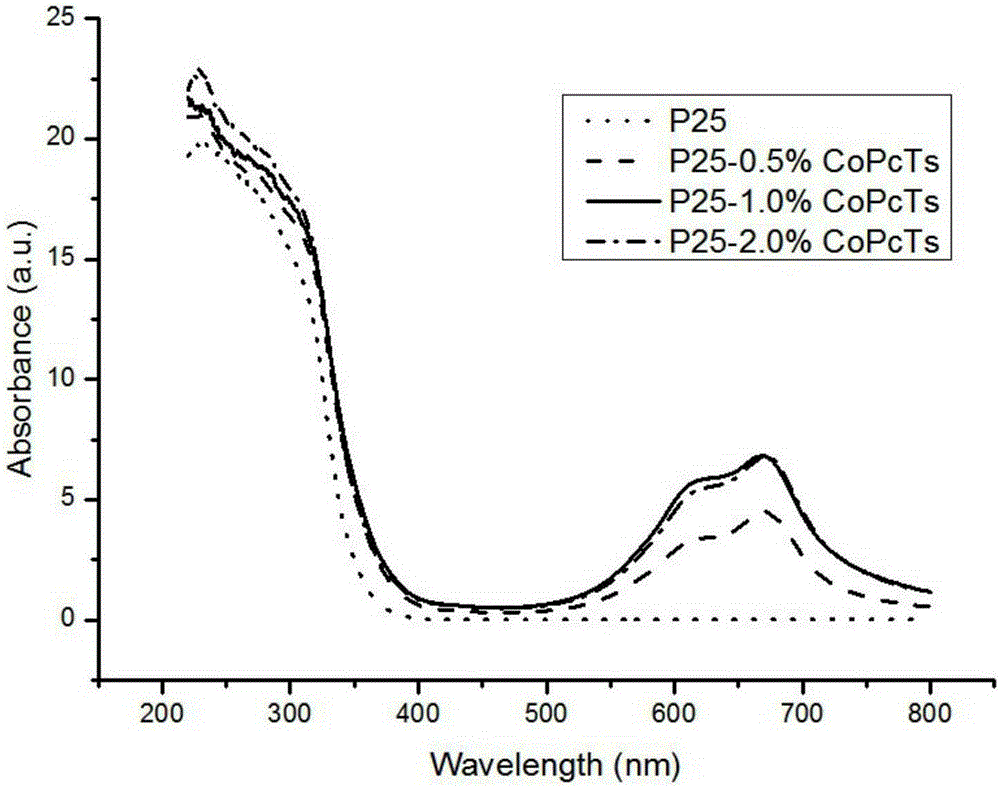

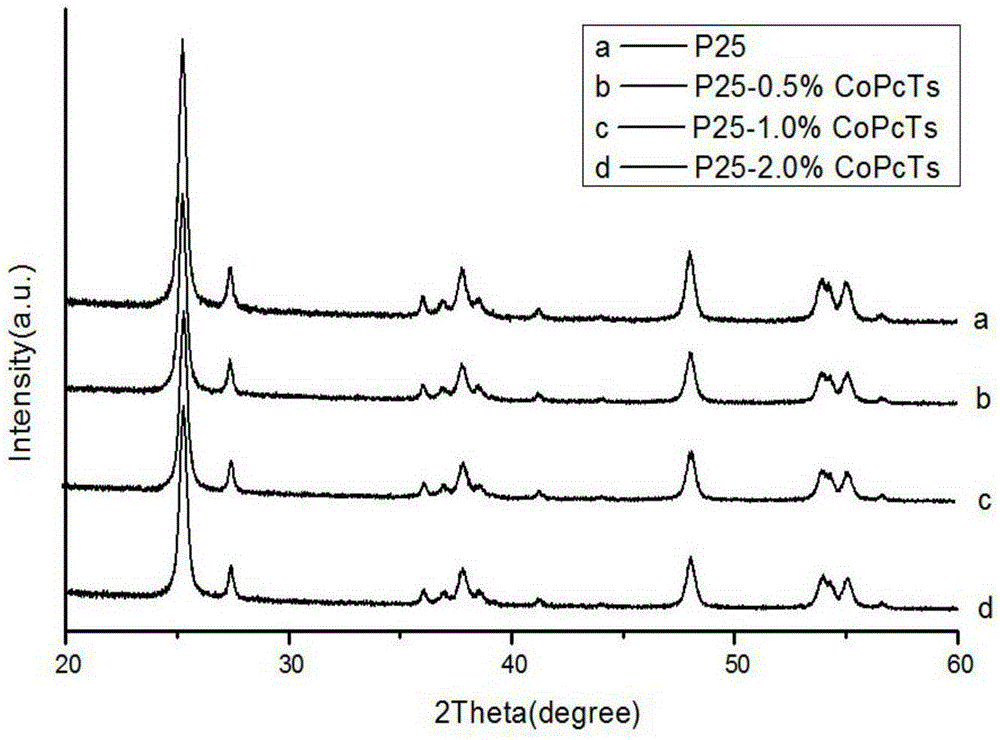

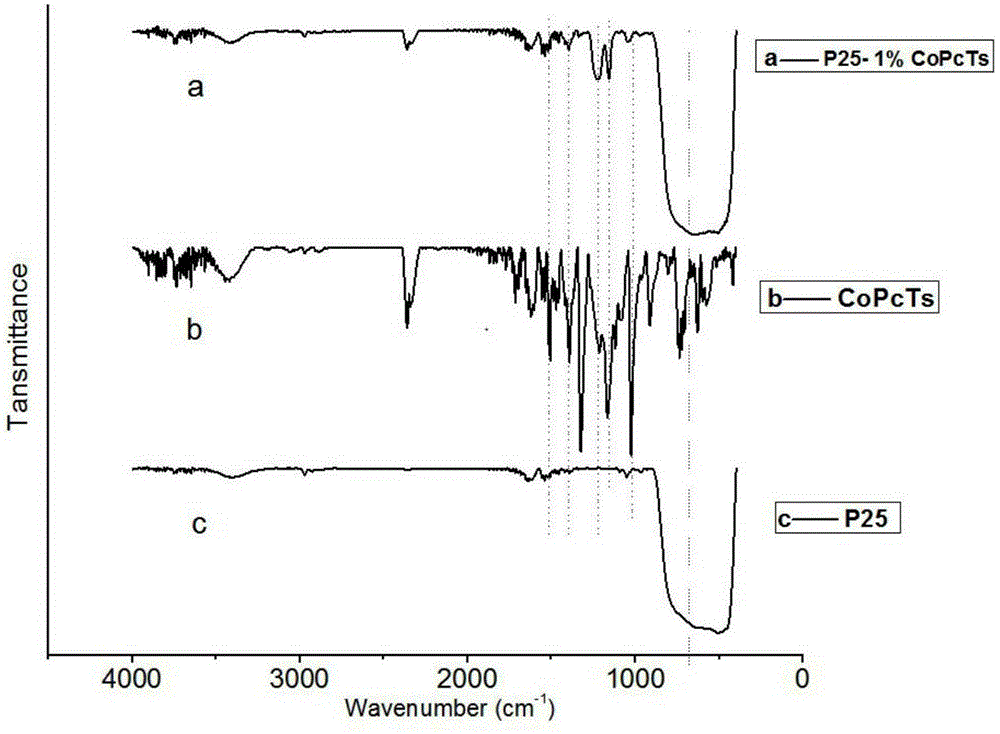

[0026] Preparation of sulfonated cobalt phthalocyanine sensitized titanium dioxide composite photocatalyst: Add 1.0gP25 to 100ml of sulfonated cobalt phthalocyanine aqueous solution with a concentration of 50mg / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com