Fenton-reaction-based improved industrial organic wastewater treatment method

A technology of organic wastewater treatment and Fenton reaction, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of large dosage, unsuitable for large-scale use, and difficult recovery of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

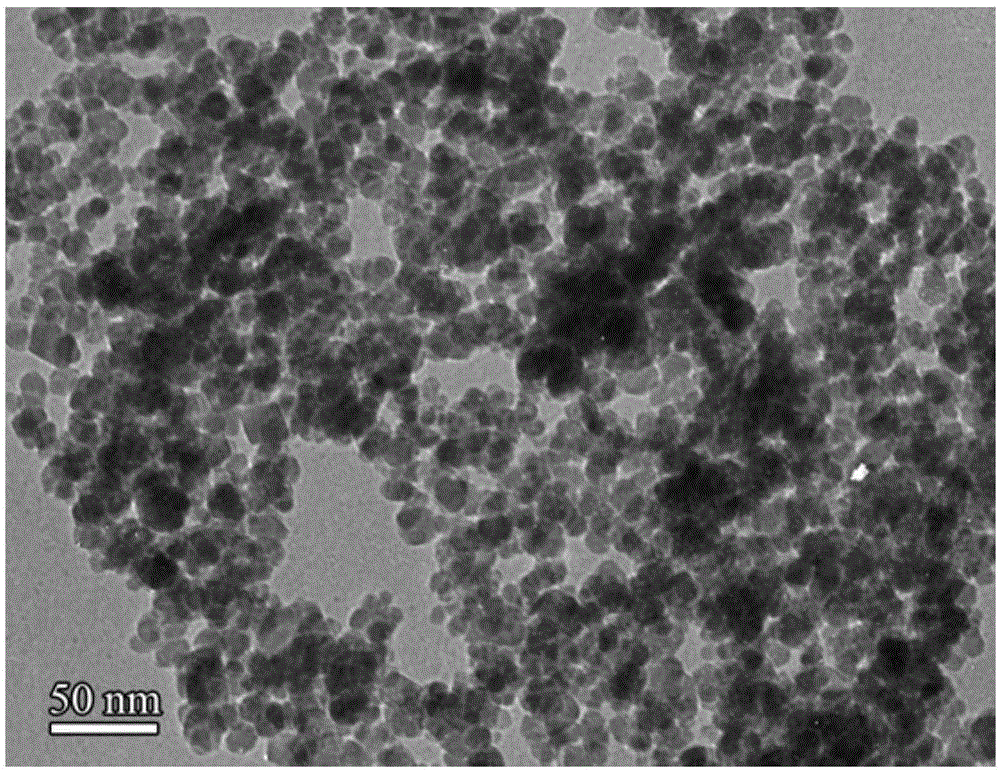

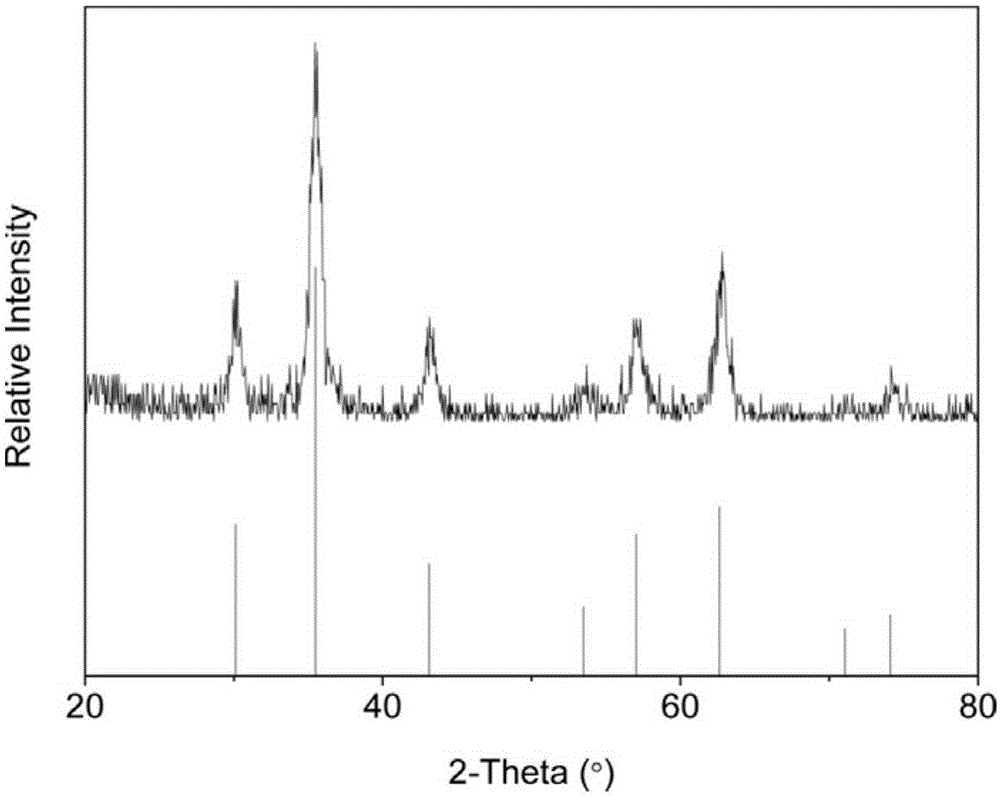

[0027] Take 50 ml of production wastewater from a citrus processing company, and the COD of the wastewater is 8427mg / L. Add 0.078g / L magnetic iron ferric oxide nanocrystal (size is 10-20nm, as figure 1 , figure 2 Shown) solution, after fully mixing, add 5 milliliters of hydrogen peroxide with a volume concentration of 30%, and irradiate with a 500-watt ultraviolet lamp for 10 hours. After the reaction, the catalyst was separated by a magnet, and the COD of the waste water was measured (results are shown in Table 1).

[0028] The magnetic ferric iron tetroxide recovered after the reaction was tested repeatedly, and the results are shown in Table 2

Embodiment 2

[0030] Take 50 ml of wastewater from a surfactant production company, and the COD of the wastewater is 113832 mg / L. Add 0.217g / L magnetic iron ferric oxide nanocrystal (size is 10-20nm, as figure 1 , figure 2 Shown) solution, after thorough mixing, add 4 milliliters of 30% hydrogen peroxide, 500 watts of ultraviolet light irradiation 8h. Add 4 milliliters of 30% hydrogen peroxide again for the second time, and continue to illuminate for 8 hours. After the reaction, the catalyst was separated by a magnet, and the COD of the waste water was measured (results are shown in Table 1).

Embodiment 3

[0032] Take 50 ml of production wastewater from an organic reagent production company, and the COD of the wastewater is 20000mg / L. Add 0.15g / L magnetic iron ferric oxide nanocrystals (size is 10-20nm, such as figure 1 , figure 2 Shown) solution, add 4 milliliters of 30% hydrogen peroxide after thorough mixing, 500 watts of ultraviolet lamps irradiate 7h. For the second time, 4 ml of 30% hydrogen peroxide was added again, and light was continued for 4 hours. Add 2 milliliters of 30% hydrogen peroxide again for the third time, and continue to illuminate for 8 hours. After the reaction, the catalyst was separated by a magnet, and the COD of the waste water was measured (results are shown in Table 1).

[0033] See Table 3 for the experimental results of adding hydrogen peroxide in batches

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com