Preparation method of intelligent gel phenol adsorption separation agent with environmental response performance

An intelligent gel phenol, adsorption and separation technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., to achieve the effect of enhancing the adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

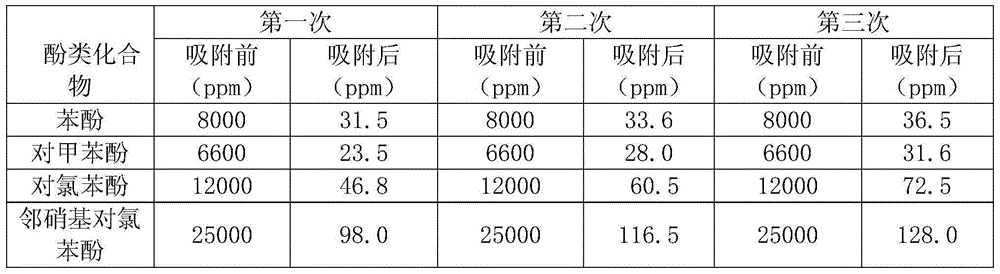

Embodiment 1

[0016] Dissolve 1 g of N-isopropylacrylamide (NIPAm) and 5 g of tributylphosphate (TBP) in 30 mL of anhydrous methanol, add 0.01 g of benzimide peroxide (BPO) and 0.01 g of N,N-methylene Bisacrylamide (Bis), reacted in a constant temperature water bath at 60°C for 24 hours, cooled to room temperature, soaked in anhydrous ethanol solution for three days to remove unreacted monomers, and then placed in 100mL volume ratio: 7 :3, 6:4, 5:5, 4:6, 3:7 mixed solution of ethanol and water, change it once a day, and finally soak it in distilled water for a week. The resulting gel was cut into pieces and dried to constant weight to prepare an intelligent gel phenolic adsorption separation agent with environmental responsiveness, namely PNIPAm / TBP.

Embodiment 2

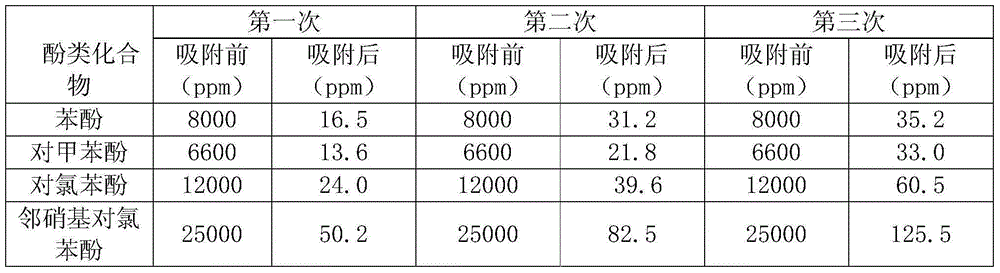

[0018] Dissolve 1 g of N-isopropylacrylamide (NIPAm) and 5 g of cyclohexane diisocyanate (HDI) in 40 mL of anhydrous methanol solution, add 0.01 g of benzimide peroxide (BPO) and 0.01 g of N,N - Methylenebisacrylamide (Bis), reacted in a constant temperature water bath at 60°C for 24 hours, cooled to room temperature and soaked in anhydrous ethanol solution for three days to remove unreacted monomers, and then placed in 100mL volume ratio respectively For: 7:3, 6:4, 5:5, 4:6, 3:7 mixed solution of ethanol and water, change it once a day, and finally soak it in distilled water for a week. The resulting gel was cut into pieces and dried to constant weight to prepare an intelligent gel phenolic adsorption separation agent with environmental responsiveness, namely PNIPAm / HDI.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com