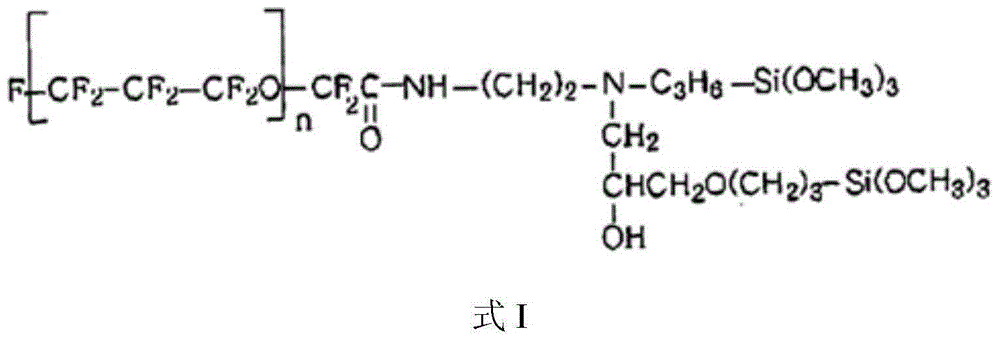

Perfluoropolyether silane, preparation method of perfluoropolyether silane and application of perfluoropolyether silane

A technology of fluoroaminosilane and reaction, which is applied in the field of perfluoropolyether silane and its preparation, can solve the problems of unrealized industrialization, and achieve the effect of low surface energy, good anti-fingerprint, and good anti-fingerprint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

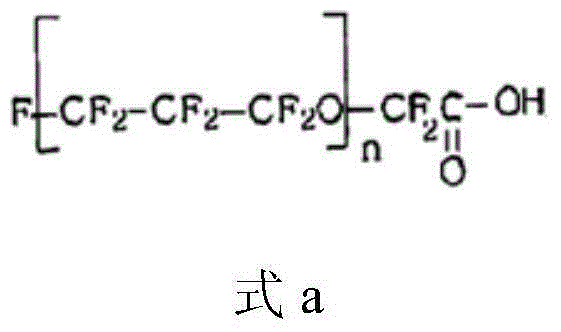

[0095] 1) Add 2.50 g of tetraglyme, 2.78 g of RbF, and 900 g of perfluorooxetane in a high-pressure stainless steel reactor equipped with a stirrer, cooling jacket, thermometer and pressure gauge, and pass through at -30 Carry out anionic polymerization reaction at ℃ for 18 hours, and the HFPO oligomer shown in formula a is obtained after the reaction is completed;

[0096]

[0097] 2) After adding 5 grams of methanol to the HFPO oligomer shown in the obtained formula a in step 1), stir and carry out esterification reaction at room temperature for 12 hours to obtain the HFPO oligomer methyl ester shown in formula b;

[0098]

[0099] Gel permeation chromatography (GPC) analysis shows that the weight average molecular weight of the HFPO oligomer methyl ester is about 8400 and n is 54.

[0100] 3) by drying in a vacuum to remove unreacted methanol, and adding 1,3-bis(trifluoromethyl)benzene to the HFPO oligomer methyl ester obtained in step 2) as a reaction solvent. Then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com