Preparation method of transparent electro-conductive nano silver wire printing ink and transparent electro-conductive membrane

A technology of transparent conductive and nano-silver wires, which is applied in the field of nano-wires, can solve the problems of unsatisfactory process requirements, large square resistance of conductive coatings, and increased production costs, and achieve easy control of production processes, low production costs, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-6

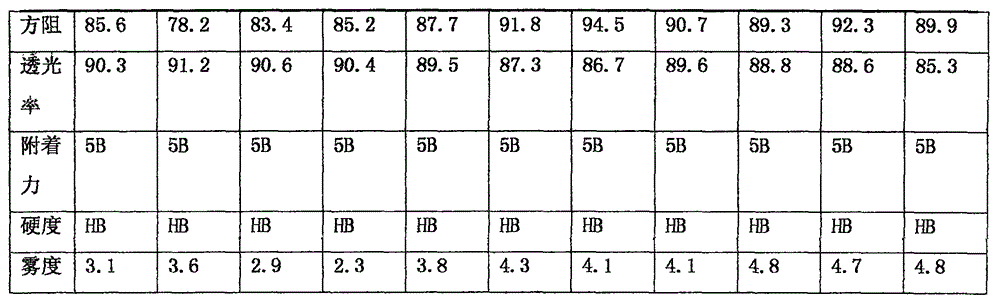

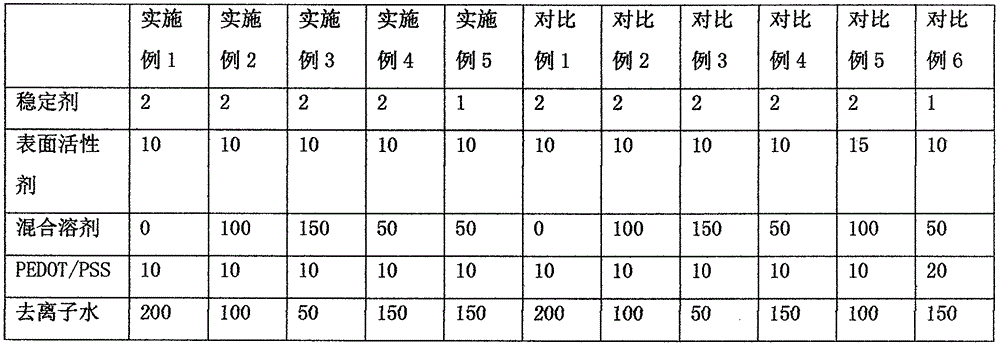

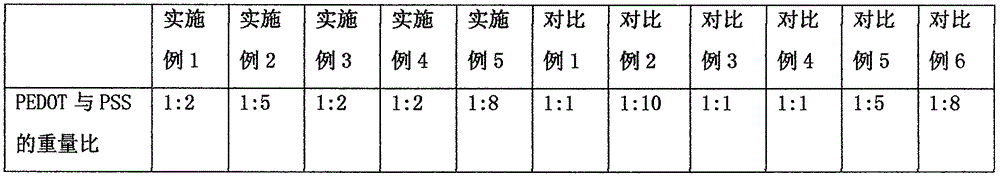

[0038] Prepare materials according to the formula in Table 1, mix them evenly, and prepare transparent inks, wherein the parameters of PEDOT / PSS used in Examples and Comparative Examples are listed in Table 2.

[0039] Transparent conductive film according to the following method: apply the ink evenly on the flexible transparent substrate, dry the ink, the wet film thickness of the ink layer is 8-15 microns; Sintering in medium for 5 minutes, a flexible transparent conductive film can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com