A kind of recombinant Bacillus subtilis accumulating acetylglucosamine and its application

A technology of Bacillus subtilis and glucosamine, which is applied in the field of genetic engineering, can solve the problems of high price of chitin hydrolase, low production intensity, long transformation time and the like, and achieves the effects of simple construction method, good application prospect and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Construction of recombinant plasmid

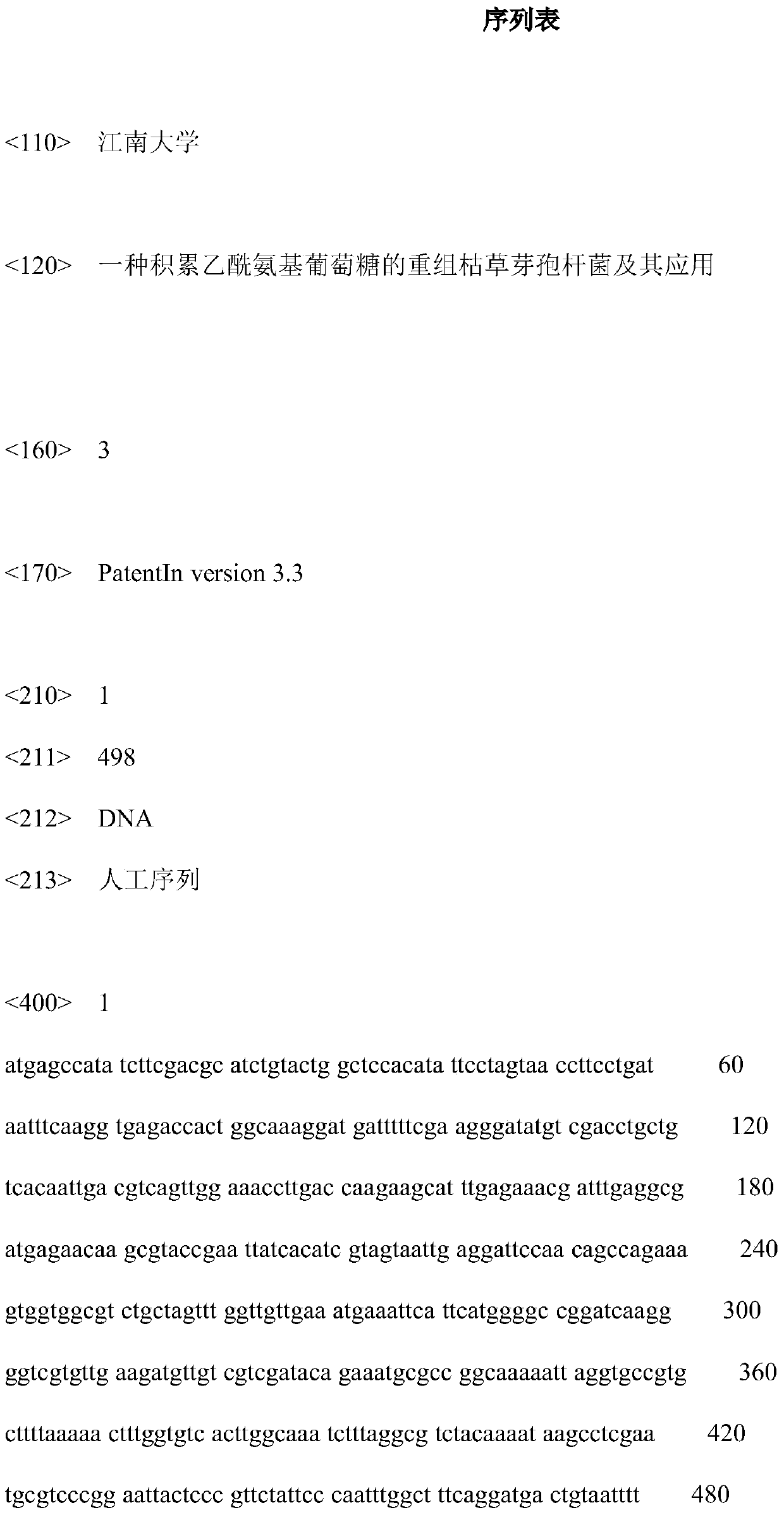

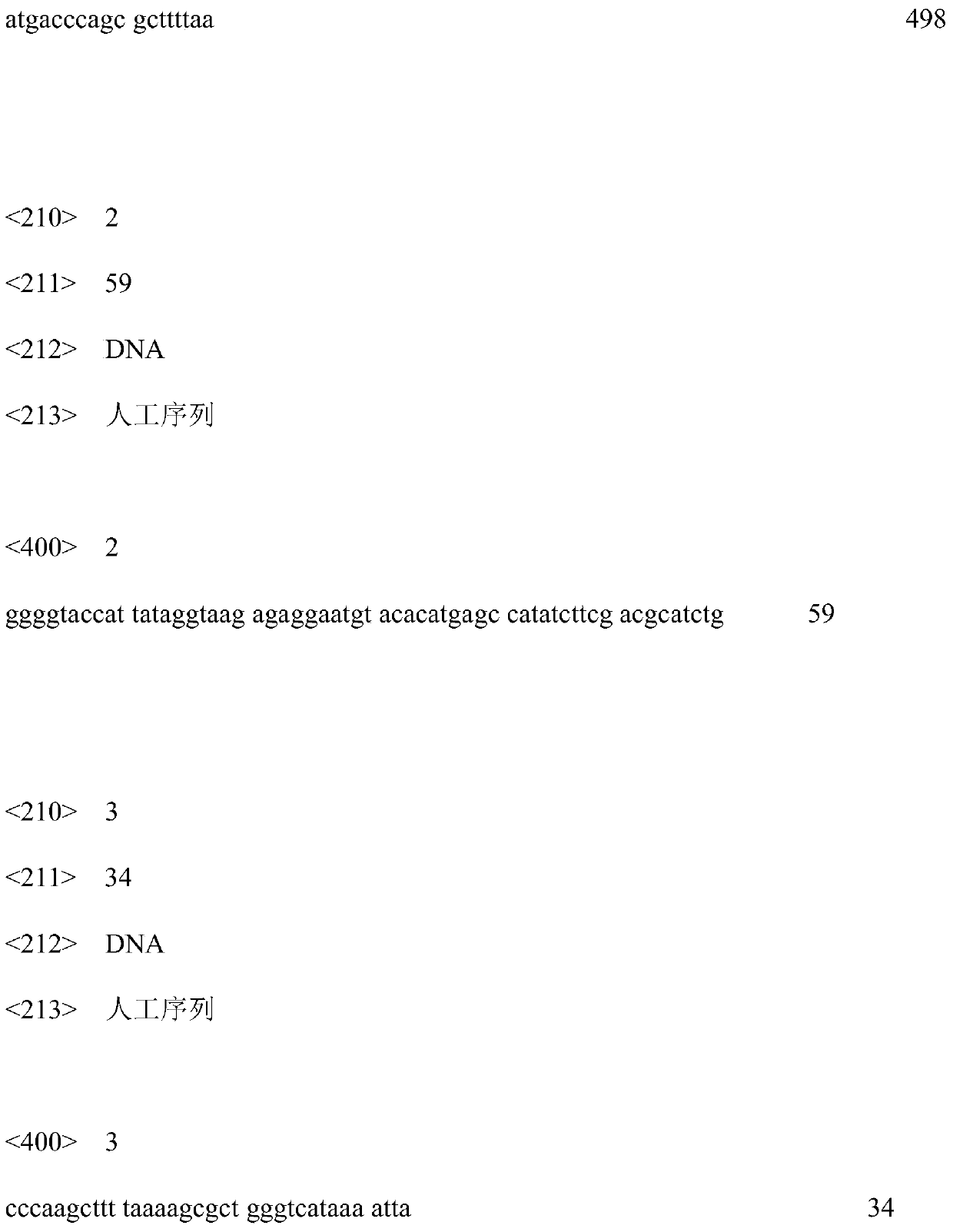

[0024] According to the nucleotide sequence of the glucosamine acetylase encoding gene (CeGNA1) in Caenorhabditis elegans published on NCBI, as shown in NCBI GenBank: AB017628.1, the codon preference of Bacillus subtilis was optimized to obtain a nuclear The nucleotide sequence is based on SEQ ID NO. 1, and the gene sequence was synthesized by Shanghai Sangon Bioengineering Co., Ltd. Design primers CeGNA1-F: 5'-GGGGTACCATTATAGGTAAGAGAGGAATGTACACATGAGCCATATCTTCGACGCATCTG-3', CeGNA1-R: 5'-CCCAAGCTTTTAAAAGCGCTGGGTCATAAAATTA-3'. The optimized glucosamine acetylase encoding gene (CeGNA1) was amplified from the synthesized nucleotide sequence SEQ ID NO. 1 using the above primers. The amplified fragment was digested with KpnI and HIndIII and then ligated into the pP43NMK expression vector. Enzyme digestion verification and sequencing confirmed that the recombinant plasmid was successfully constructed and named pP43-CeGNA1. For...

Embodiment 2

[0025] Example 2 Construction of recombinant Bacillus subtilis

[0026] The constructed expression vector pP43-CeGNA1 was transformed into recombinant Bacillus subtilis BSGN6-PxylA-glmS. Using CeGNA1-F and CeGNA1-R primers to select transformants for colony PCR, a 498bp band appeared, verifying that the recombinant Bacillus subtilis was successfully constructed.

Embodiment 3

[0027] Embodiment 3 Fermentation produces acetylglucosamine

[0028] The seeds cultured at 37°C and 200 rpm for 12 hours were transferred to the fermentation medium with 5% inoculum and cultured at 37°C and 200 rpm for 30 hours. The content of acetylglucosamine in the final fermentation supernatant reached 7.31 g / L. The control strain took BSGN6-PxylA-glmS as the starting strain, overexpressed the glucosamine acetylase encoding gene GNA1 (nucleotide sequence such as NCBI GenBank: NM_001179949) derived from Saccharomyces cerevisiae S288C, and finally fermented under the same culture conditions The content of acetylglucosamine in the supernatant reached 5.87g / L. By comparison, the production of acetylglucosamine in the fermentation supernatant of recombinant Bacillus subtilis expressing the C. elegans-derived CeGNA1 gene was increased by 24.51% compared with the control strain expressing the Saccharomyces cerevisiae-derived GNA1 gene. The extracellular accumulation of acetylgl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com