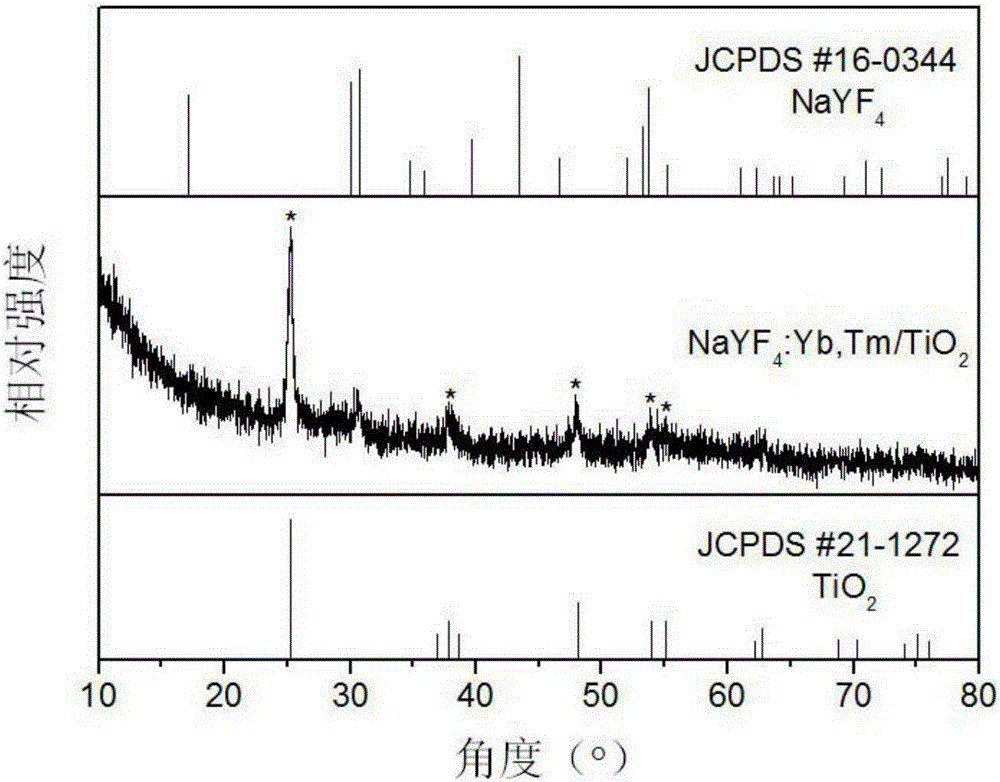

NaYF4:Yb,Tm/TiO2 composite nanofiber and preparation method thereof

A technology of composite nanofibers and nanoparticles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, complicated preparation method operation, poor photocatalytic effect, etc., and achieve cost Low cost, simple operation process, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

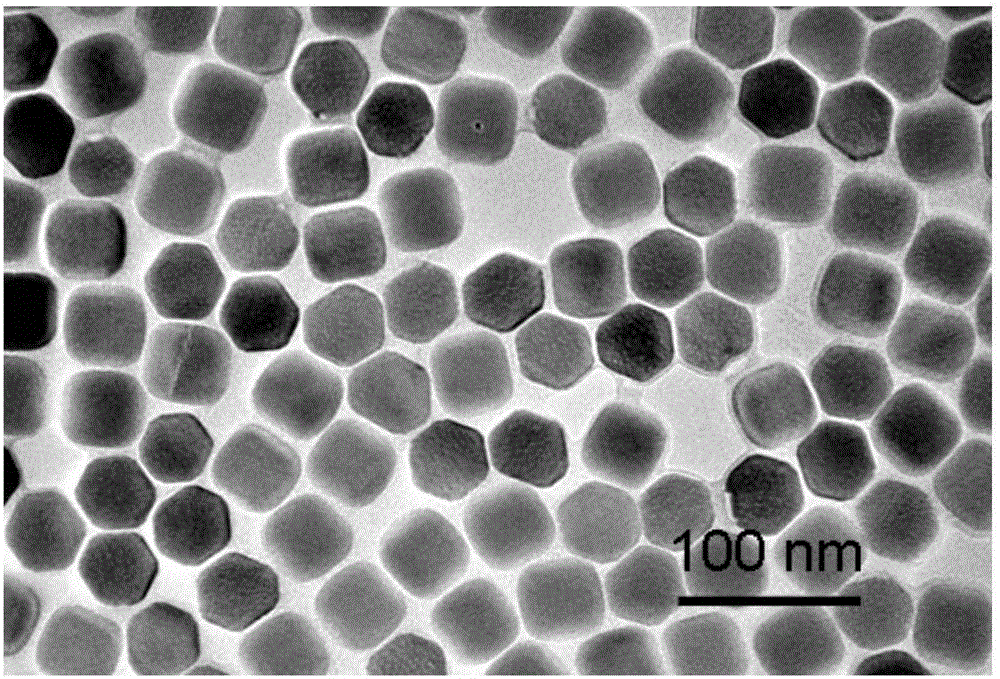

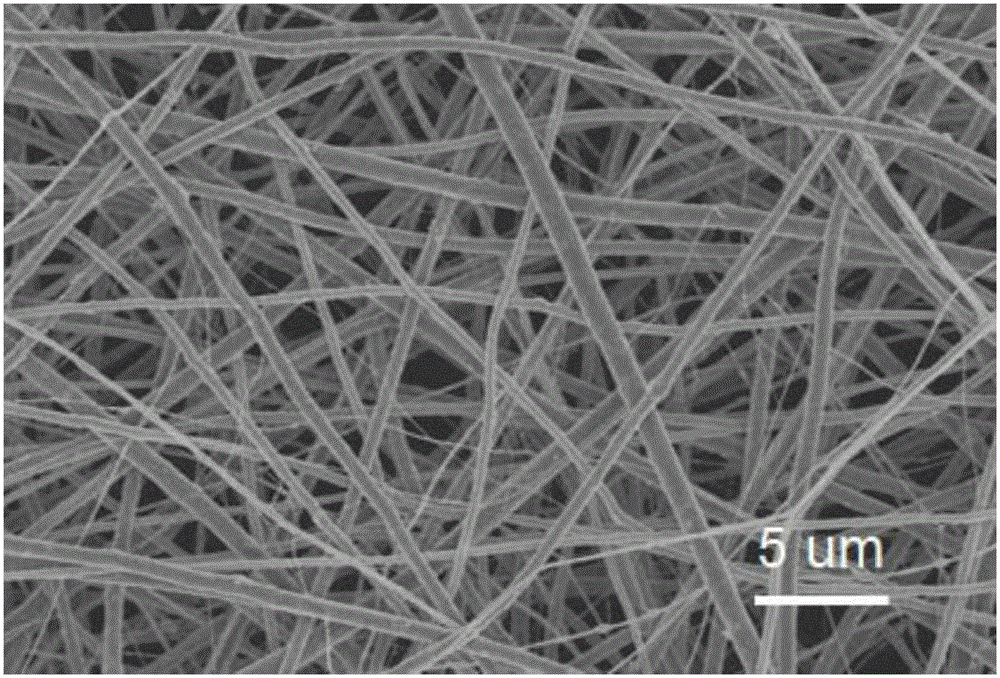

[0035] This embodiment prepares NaYF according to the following steps 4 :Yb,Tm / TiO 2 Composite nanofibers:

[0036] 1. Preparation of water-soluble NaYF 4 :Yb,Tm nanoparticles:

[0037] a. Weigh 0.1357gYCl 3 , 0.0838gYbCl 3 and 0.0014gTmCl 3 Put it into the reactor, add 5mL oleic acid and 15mL octadecene, stir evenly, heat to 150°C and keep it warm at this temperature for 0.5h to obtain a clear clear liquid; cool the clear clear liquid to room temperature, add 4mL solvent dropwise There are 0.3652gNH 4 F and 0.2464g NaOH methanol solution, stirred at room temperature for 0.5h, then heated to 150°C and kept for 0.5h to remove methanol, and finally heated to 240°C under nitrogen protection flow, kept for 2h to obtain NaYF 4 : Yb, Tm nanoparticles;

[0038] b. Weigh 100 mg of NaYF prepared in step a 4 : Yb, Tm nanoparticles in the flask, add 20mL of hydrochloric acid solution of pH 1 to disperse, stir at room temperature for 2h, and centrifuge to obtain water-soluble NaY...

Embodiment 2

[0048] This embodiment prepares NaYF according to the following steps 4 :Yb,Tm / TiO 2 Composite nanofibers:

[0049] 1. Preparation of water-soluble NaYF 4 :Yb,Tm nanoparticles:

[0050] a. Weigh 0.6845gYCl 3 , 0.4192gYbCl 3 and 0.007gTmCl 3 Put it into the reactor, add 10mL oleic acid and 10mL octadecene, stir evenly, heat to 80°C and keep it at this temperature for 2h to obtain a clear clear liquid; cool the clear clear liquid to room temperature, add 4mL of dissolved 1.826gNH 4 F and methanol solution of 1.232g NaOH, stirred and reacted at room temperature for 1h, then heated to 100°C and kept for 0.5h to remove methanol, and finally heated to 320°C under nitrogen protection flow, kept for 0.5h to obtain NaYF 4 : Yb, Tm nanoparticles;

[0051] b. Weigh 500 mg of NaYF prepared in step a 4 : Yb, Tm nanoparticles in a flask, add 20mL of pH 3 hydrochloric acid solution to disperse, stir at room temperature for 4h, and centrifuge to obtain water-soluble NaYF 4 : Yb, Tm ...

Embodiment 3

[0057] This embodiment prepares NaYF according to the following steps 4 :Yb,Tm / TiO 2 Composite nanofibers:

[0058] 1. Preparation of water-soluble NaYF 4 :Yb,Tm nanoparticles:

[0059] a. Weigh 0.1643gYCl 3 , 0.1013gYbCl 3 and 0.0017gTmCl 3 Put it into the reactor, add 6mL oleic acid and 14mL octadecene, stir evenly, heat to 130°C and keep warm at this temperature for 0.5h to obtain a clear clear liquid; cool the clear clear liquid to room temperature, and add 10mL of solvent dropwise There are 0.4276gNH 4 F and 0.3742g NaOH in methanol solution, stirred at room temperature for 2h, then heated to 80°C for 1h to remove methanol, and finally heated to 340°C under nitrogen protection flow, and kept for 0.5h to obtain NaYF 4 : Yb, Tm nanoparticles;

[0060] b. Weigh 200 mg of NaYF prepared in step a 4 : Yb, Tm nanoparticles in a flask, add 20mL of hydrochloric acid solution with pH 1.5 to disperse, stir at room temperature for 2.5h, and centrifuge to obtain water-soluble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com