Rotary gasification combustion device and gasification combustion process

A combustion device and rotary technology, which is applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of high operating requirements, difficulty in miniaturization, and return feeding, etc., to improve the effect of gas-solid phase reaction and maintain temperature stability and uniform, adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described below in conjunction with the drawings.

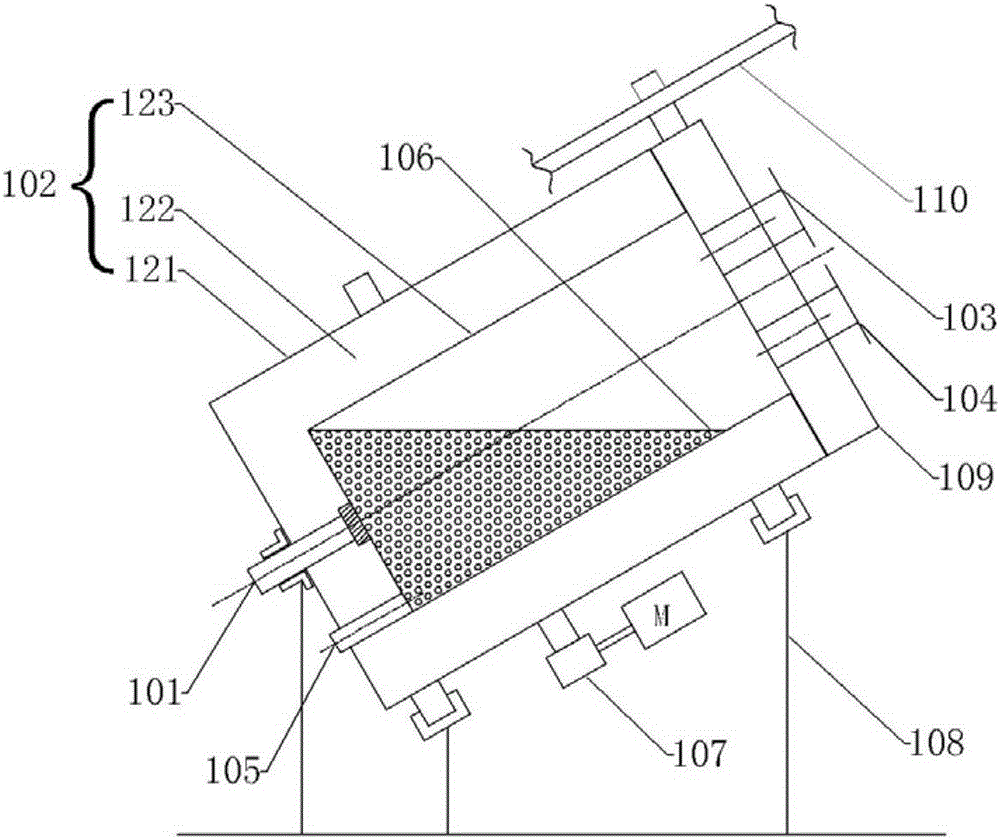

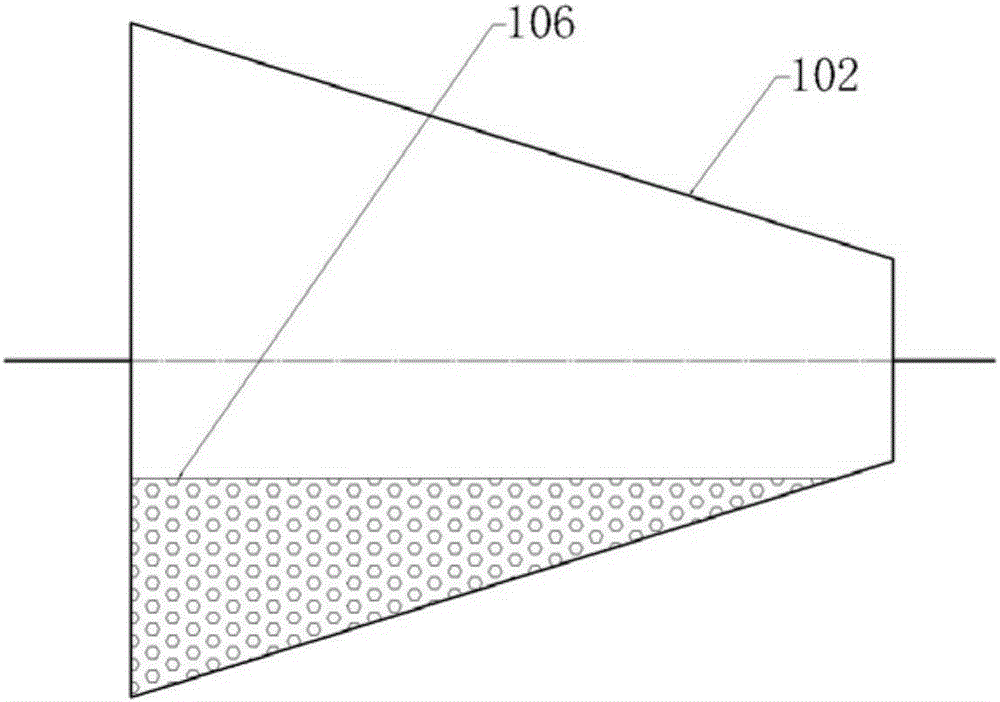

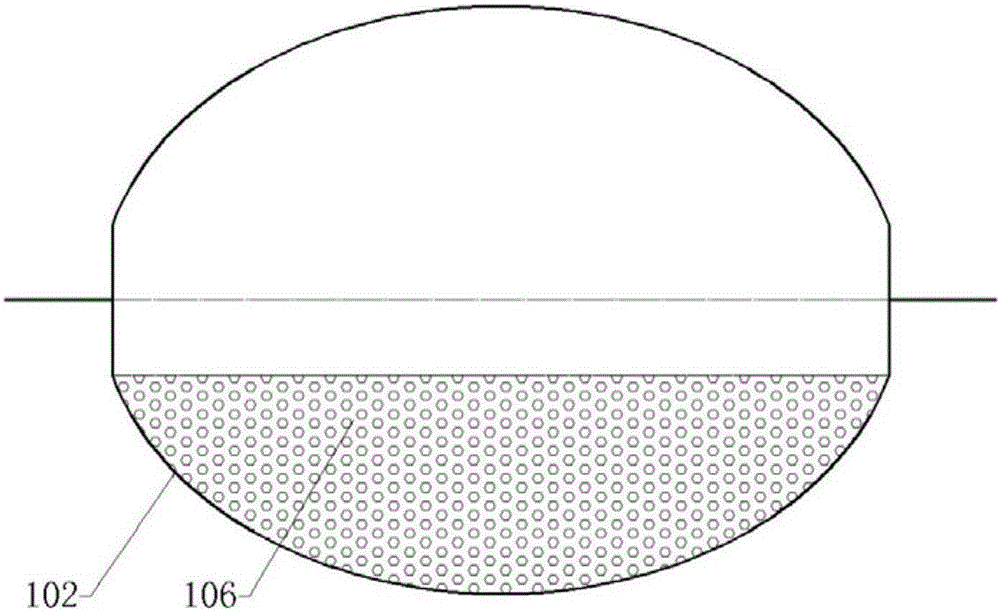

[0044] Such as figure 1 As shown, the rotating cylinder 102 is placed on the fixed frame 108, supported by four supporting wheels to rotate, and the ring gear is fixed on the rotating cylinder 102, which is driven by meshing with the pinion gear of the reducer 107, and the reducer 107 is straight with the motor coupling. The rotation speed of the revolving cylinder 102 can be controlled by a frequency converter, and the speed adjustment range is 2-6r / min; a thrust bearing is arranged at the bottom of the revolving cylinder 102 to maintain the rotation of the revolving cylinder 102 at a large angle; the cover plate 109 is installed on the guide On the rod 110, the cover plate 109 can move in the axial direction, which facilitates the opening and closing of the cover plate 109, the replacement of the solid bed material 106, and the internal cleaning and maintenance op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com