Production method of diffusion plate

A production method and diffusion plate technology, which is applied in the field of lighting, can solve the problems that the shading and light transmission cannot meet the use requirements, increase the cost, increase the assembly man-hours, etc., so as to improve the shading and light transmittance, easy to operate, and save energy. The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

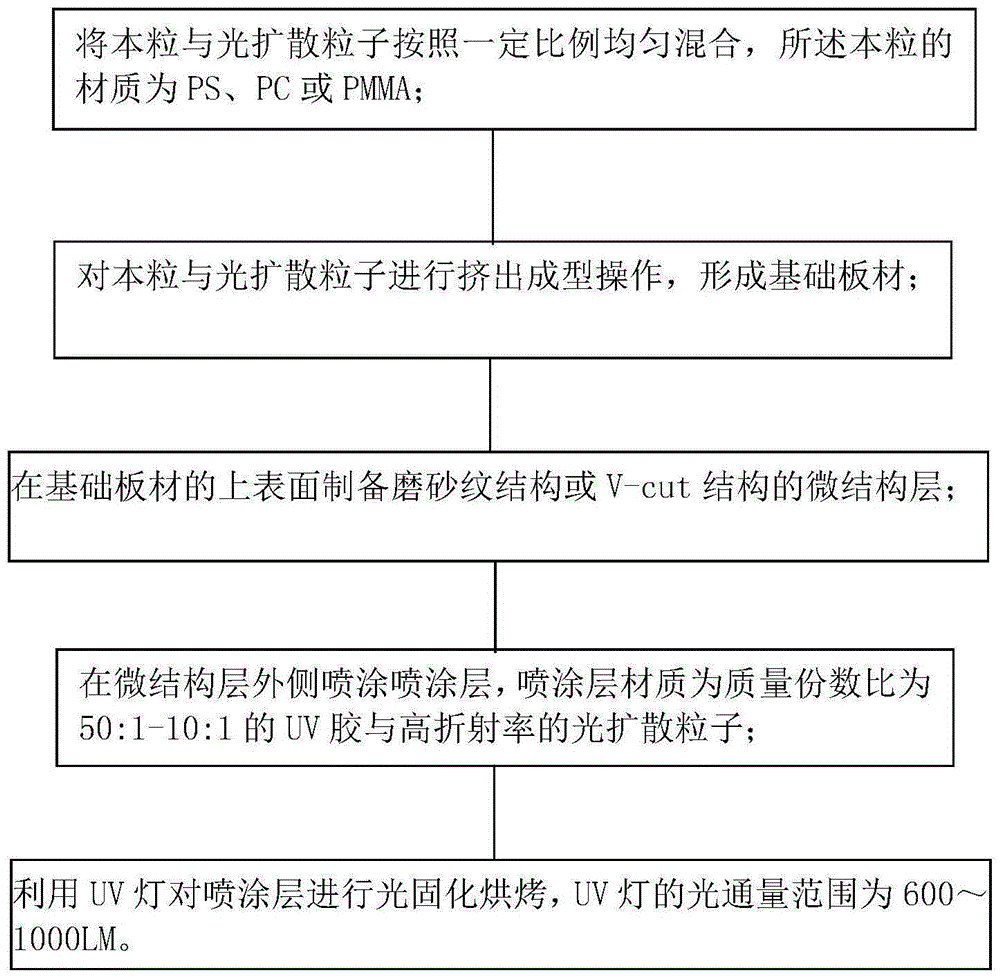

[0023] Such as figure 1 Shown, the method for producing diffusion plate of the present invention comprises the following steps:

[0024] 1. Mix PS, PC or PMMA material with the light-diffusing particles evenly according to the haze requirements. The mass-number ratio of the main particles and the light-diffusing particles is 1:0.2~1:2, for example, it can be 1:0.2 ,1:0.5,1:1,1:1.5,1:1.8 etc.

[0025] 2. Extrude the above-mentioned particles and light-diffusing particles to form a base plate.

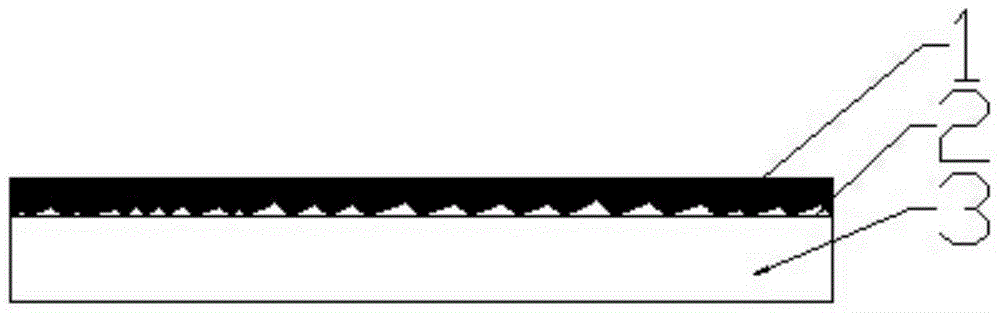

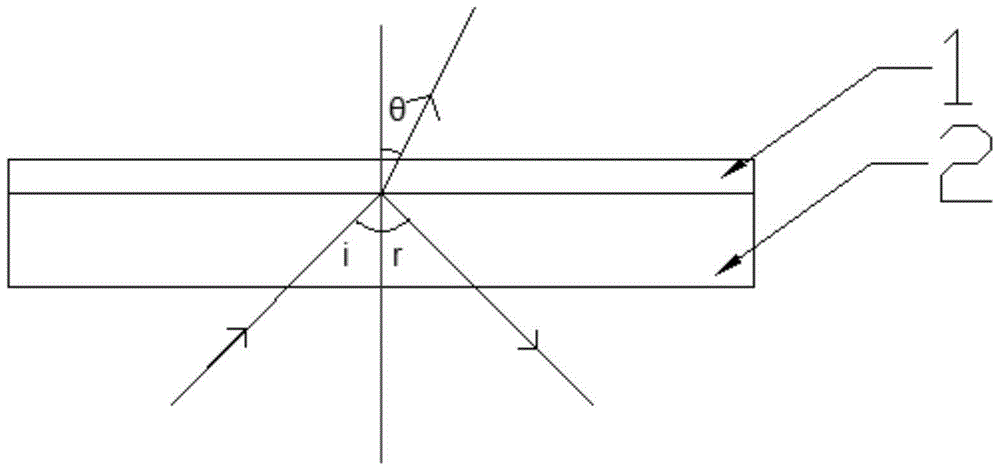

[0026] 3. Using an embossing process to prepare a microstructure layer on a single surface or both surfaces on the left and right sides of the base plate, the microstructure layer is a frosted grain structure or a V-cut structure.

[0027] The V-cut structure is a tiny zigzag or semicircular structure, its function is to guide the light from the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com