High-strength and wear-resistant cable

A fire-resistant cable, high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor strength and wear resistance, general performance, cable cracks, etc., to improve mechanical properties, improve interface adhesion, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

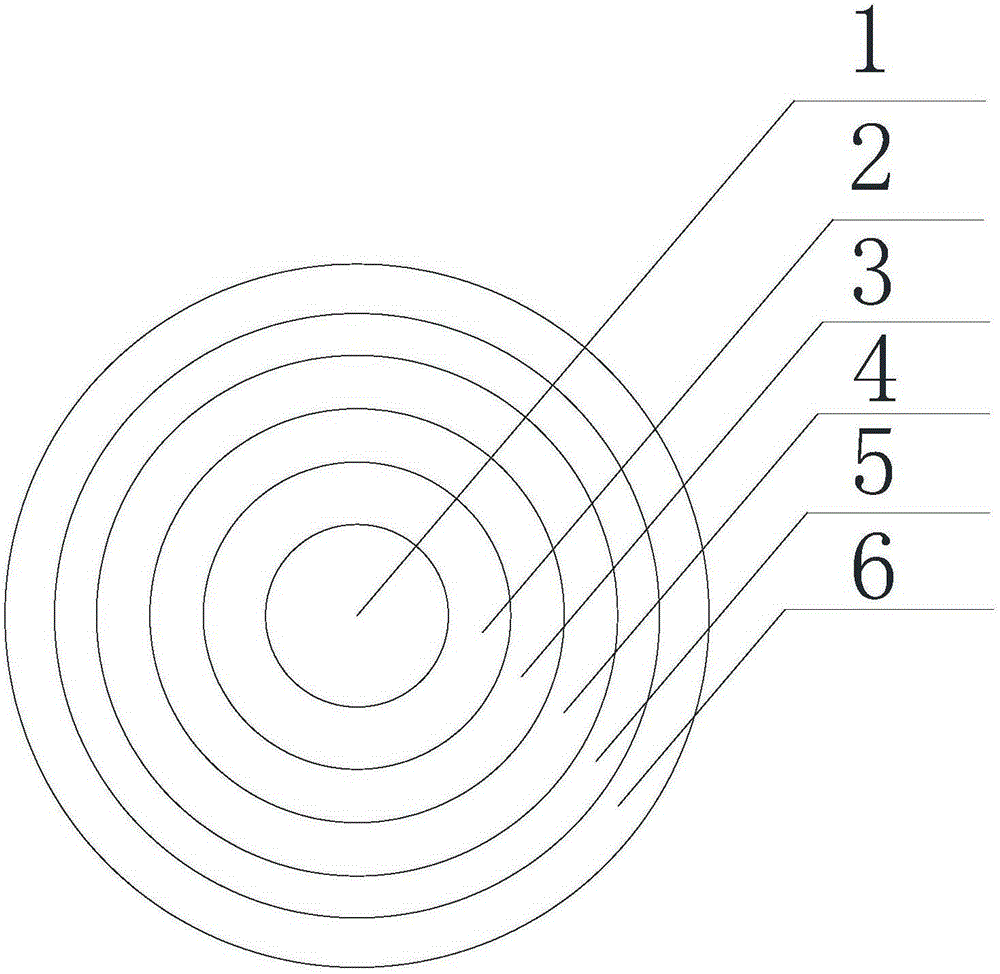

[0016] Such as figure 1 as shown, figure 1 It is a schematic diagram of the radial cross-sectional structure of a high-strength wear-resistant and fire-resistant cable proposed by the present invention.

[0017] refer to figure 1 , a high-strength wear-resistant and fire-resistant cable proposed by the present invention, comprising a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, a covering shield The armor layer 5 of the layer 4 and the outer sheath 6 covering the armor layer 5;

[0018] The raw materials of the outer sheath 6 include by weight: 65 parts of natural rubber, 20 parts of chloroprene rubber, 20 parts of butyl rubber, 12 parts of polytetrafluoroethylene modified aramid pulp material, dicumyl peroxide DCP1 .8 parts, 2.2 parts of sulfur, 1.9 parts of sodium cinnamate, 1.4 parts of triethanolamine, 22 parts of barite powder, 7 parts of magnesium oxide...

Embodiment 2

[0021] A high-strength wear-resistant and fire-resistant cable proposed by the present invention includes a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, and a covering shielding layer The armor layer 5 of 4 and the outer sheath 6 covering the armor layer 5;

[0022] The raw materials of the outer sheath 6 include by weight: 60 parts of natural rubber, 23 parts of chloroprene rubber, 17 parts of butyl rubber, 15 parts of polytetrafluoroethylene modified aramid pulp material, dicumyl peroxide DCP1 .5 parts, 2.5 parts of sulfur, 1.6 parts of sodium cinnamate, 1.7 parts of triethanolamine, 18 parts of barite powder, 10 parts of magnesium oxide, 5 parts of sepiolite powder, 9 parts of hard clay, titanate coupling agent KR- 1.6 parts of TTS, 8 parts of magnesium hydroxide, 8 parts of trioctyl trimellitate, 1.8 parts of anti-aging agent 800-A, 1.2 parts of anti-aging a...

Embodiment 3

[0025] A high-strength wear-resistant and fire-resistant cable proposed by the present invention includes a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, and a covering shielding layer The armor layer 5 of 4 and the outer sheath 6 covering the armor layer 5;

[0026] The raw materials of the outer sheath 6 include by weight: 63 parts of natural rubber, 21 parts of chloroprene rubber, 19 parts of butyl rubber, 13 parts of polytetrafluoroethylene modified aramid pulp material, dicumyl peroxide DCP1. 7 parts, 2.3 parts of sulfur, 1.8 parts of sodium cinnamate, 1.5 parts of triethanolamine, 20 parts of barite powder, 8 parts of magnesium oxide, 7 parts of sepiolite powder, 7 parts of hard clay, titanate coupling agent KR-TTS2 5 parts, 5 parts of magnesium hydroxide, 9 parts of trioctyl trimellitate, 1.6 parts of antioxidant 800-A, 1.4 parts of antioxidant 40201.4 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com