Buried-channel SiC trench gate metal oxide semiconductor field effect transistors (MOSFETs) device and fabrication method thereof

A technology of silicon carbide trench and silicon carbide, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high threshold voltage and on-resistance, influence of effective electron mobility, and difficulty in practical use. Achieve the effect of avoiding high threshold voltage, avoiding low effective mobility, and improving effective mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

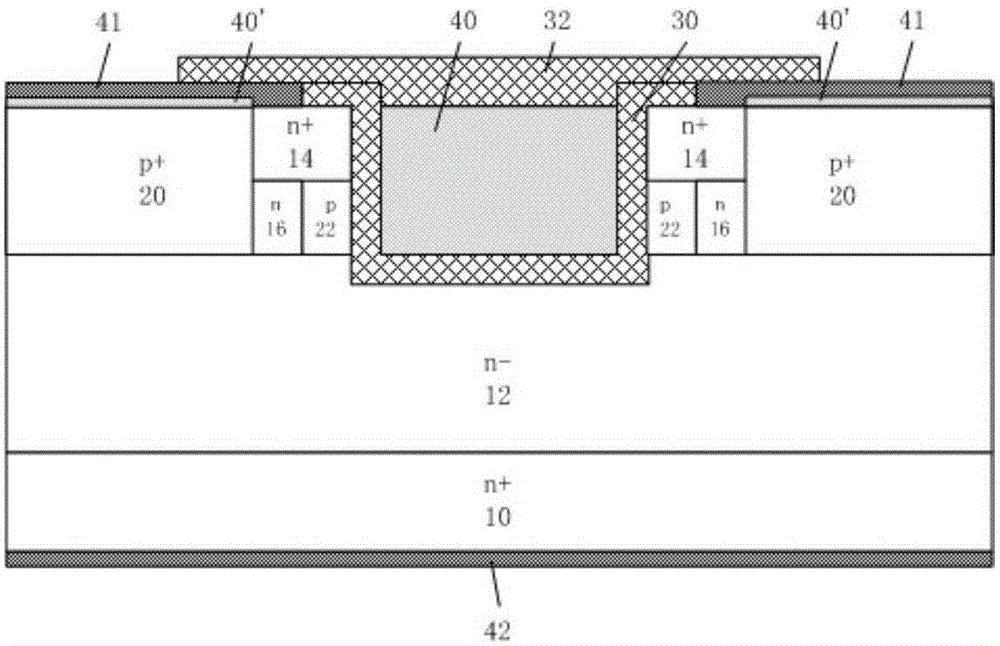

[0098] The device fabrication of the embodiment of the present invention can refer to Figure 4-13 description of.

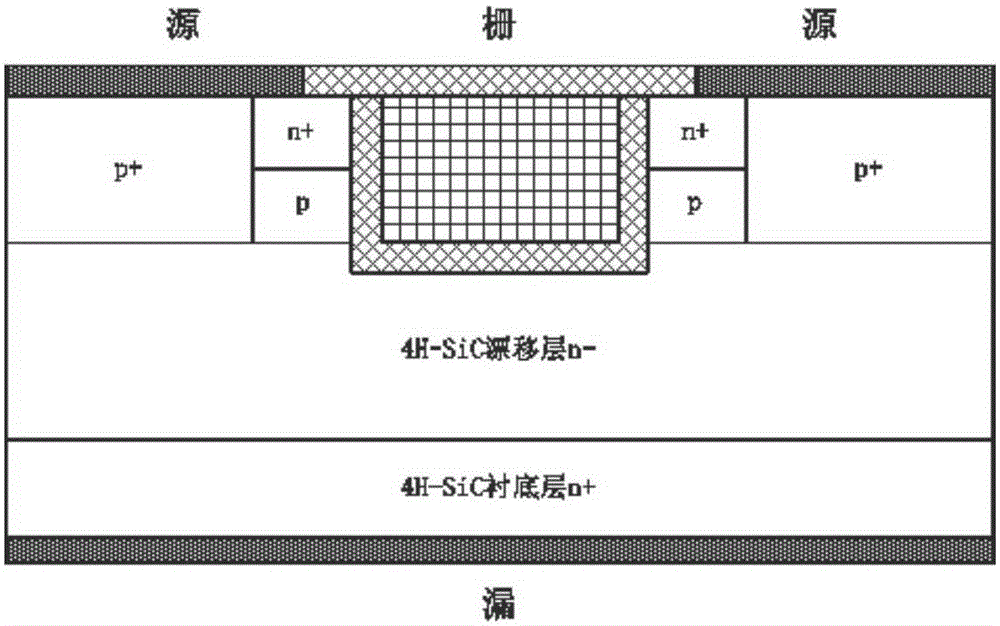

[0099] in such as Figure 4 On the n-type silicon carbide substrate 10 shown and the n-type silicon carbide drift layer 12 thereon, an ion implantation mask is formed and patterned, and p-type doped impurity aluminum is implanted into the n-type layer 12 to form a Figure 5 P+ silicon carbide regions 20 are shown with spacing.

[0100] Such as Figure 6 As shown, an n+ silicon carbide source region 14 is formed on the p+ silicon carbide region 20 and the n-type silicon carbide drift layer 12 by making a masking film and patterning it and then ion-implanting nitrogen.

[0101] Such as Figure 7 As shown, the implantation of low-dose nitrogen-doped impurities is continued to provide n-type doped regions 16 between the p+-type silicon carbide regions 20 .

[0102] Such as Figure 8 As shown, polysilicon is deposited, polysilicon is etched, an implantation mas...

Embodiment 2

[0110] The device fabrication of the embodiment of the present invention can refer to Figure 14-17 and Figure 10-13 description of,

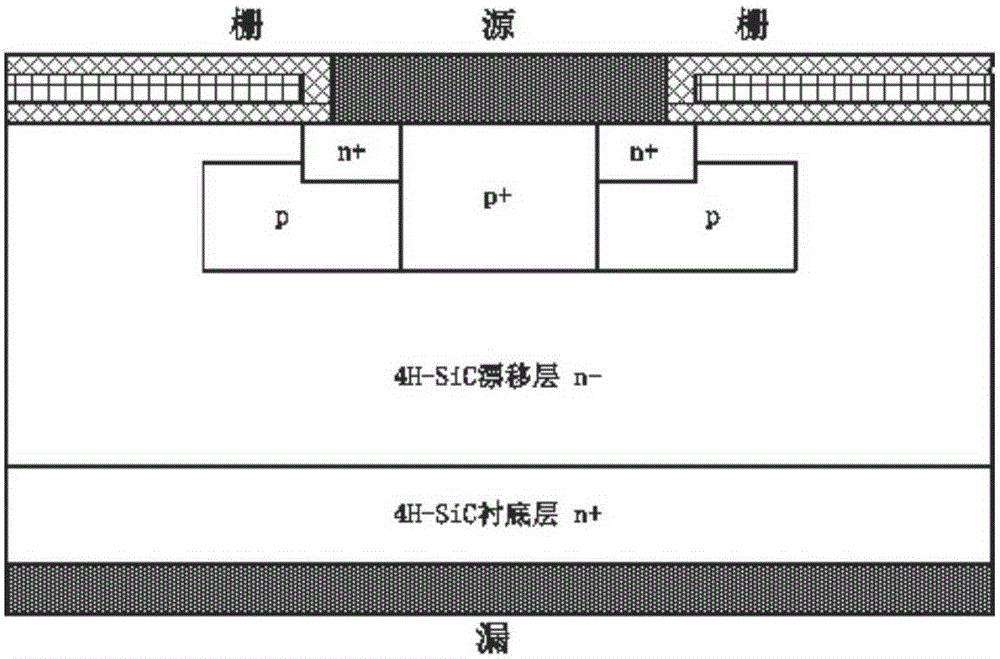

[0111] in such as Figure 14 On the n-type silicon carbide substrate 10 shown and the n-type silicon carbide drift layer 12, the n-type silicon carbide doped layer 16 and the n+ type silicon carbide doped layer 14 thereon, an ion implantation mask is formed and patterned , implanting p-type doped impurity aluminum, forming such as Figure 15 P+ silicon carbide regions 20 are shown with spacing.

[0112] Such as Figure 16 As shown, a p-type silicon carbide doped region 22 is formed on the p+ silicon carbide region 20 and the n+ type silicon carbide layer 14 by making a masking film and patterning it and implanting aluminum.

[0113] Such as Figure 17 As shown, silicon oxide is deposited, silicon oxide is etched, annealed to form an etching mask for the trench, silicon carbide is etched, and the surface of the n+ silicon carbide source r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com