Novel electrode material of sodium-ion battery and application of electrode material

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance of sodium ion batteries, easy precipitation of sodium deposition, low Coulombic efficiency, etc., to promote high-speed migration, safety Good sex, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

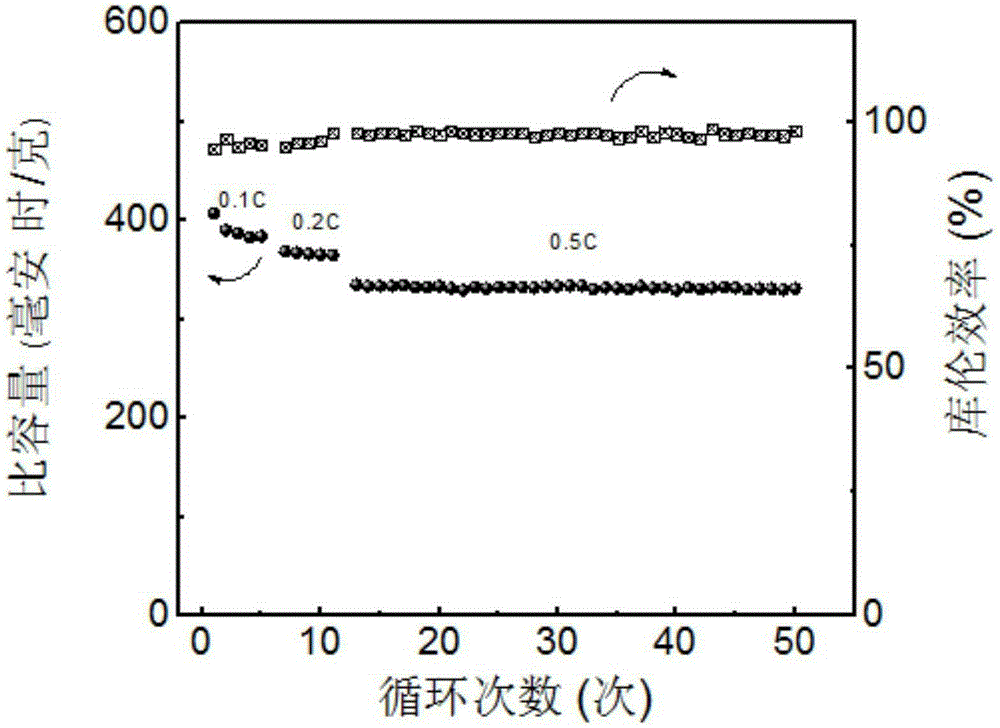

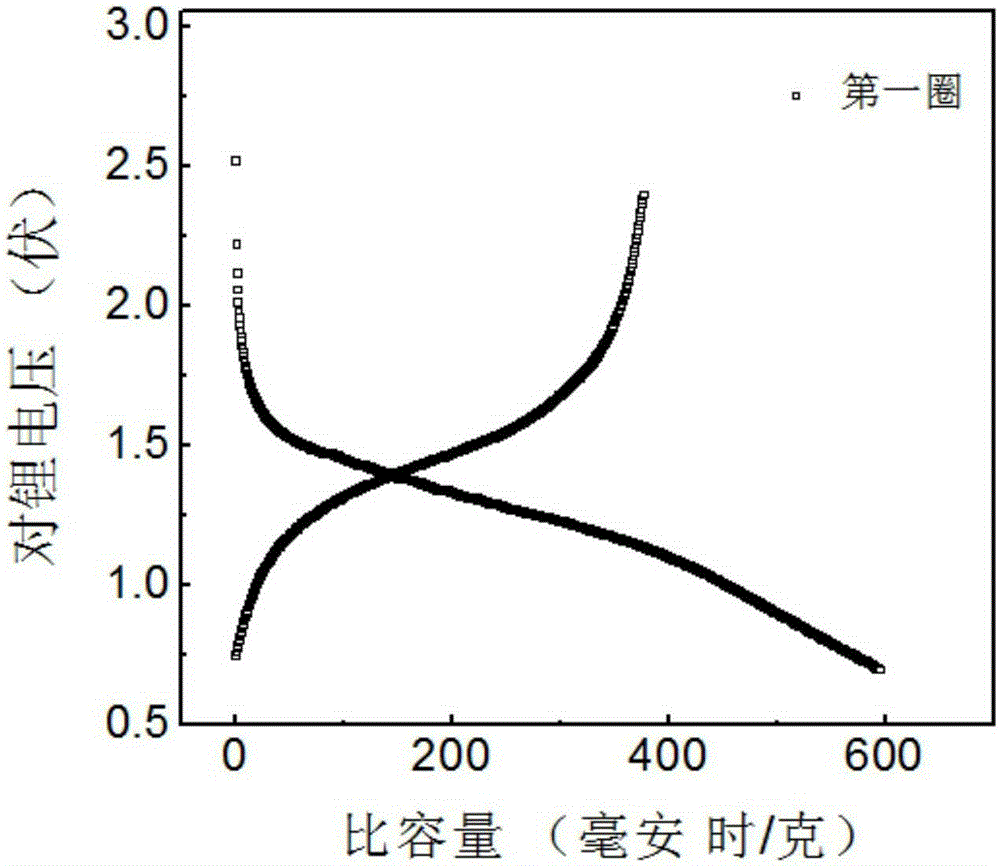

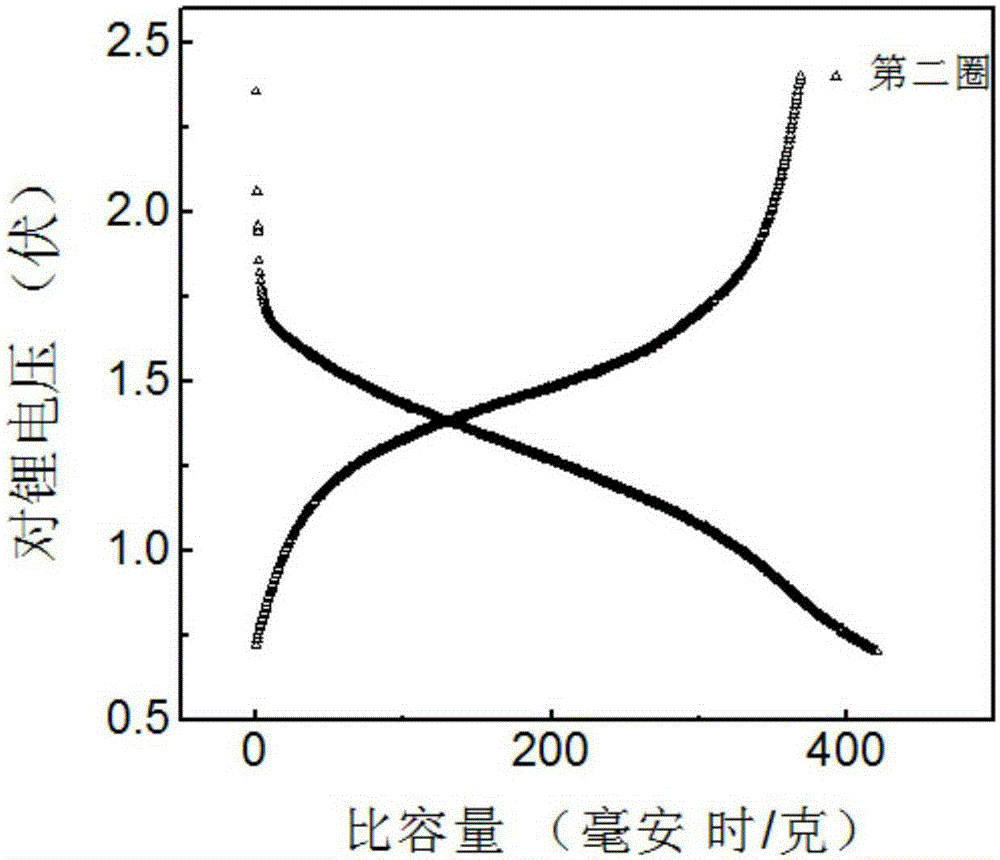

[0041] Example 1, tellurium / CMK-1 / copper telluride composite electrode and its electrochemical performance test in sodium ion battery

[0042] 1-1 Preparation of tellurium / CMK-1 / copper telluride composites

[0043] After ball milling elemental tellurium and mesoporous carbon material CMK-1 for 12h, keep at 600°C for 15h under argon atmosphere, then keep at 400°C for 6h, add copper telluride and mix ball mill for 10h, and keep at 400°C for 6h under argon atmosphere , and then stop heating and cool to room temperature to obtain a tellurium / CMK-1 / copper telluride carrier composite material, wherein the molar ratio is tellurium: CMK-1: copper telluride = 1:1:2, and the pore diameter of CMK-1 is 4nm, The specific surface area reaches 2000m 2 / g, the pore volume is 1.3cm 3 / g.

[0044] 1-2 Preparation of tellurium / CMK-1 / copper telluride composite electrode

[0045] The electrode includes the active material prepared above, a conductive additive and a binder. Wherein, the conduc...

Embodiment 2

[0066] Other conditions are identical with embodiment 1, and difference is only that active material is tellurium / single-layer graphene / copper telluride composite material, replaces CMK-1 with the single-layer graphene of equimolar amount, the specific surface area of single-layer graphene 2200m 2 / g. The sodium-tellurium battery composed of the prepared electrode and metal sodium was tested. The discharge capacity of the first cycle was 505mAh / g, and after 40 cycles, the capacity could be maintained at 373mAh / g.

[0067] 2-4a Assembly of Na-ion battery

[0068] The only difference from 1-4a is that the first-cycle discharge capacity of the tellurium electrode material obtained in Example 2 is 390mAh / g at 0.1C, and 329mAh / g at 0.5C, and the capacity retention after 50 cycles is still 310mAh / g.

[0069] 2-4b Assembly of Na-ion battery

[0070] The only difference from 1-4b is that using the tellurium electrode material obtained in Example 2, the charge-discharge curve und...

Embodiment 3

[0074] Other conditions are the same as in Example 1, except that the active material is a tellurium / double-walled carbon nanotube / copper telluride composite material, and double-walled carbon nanotubes in equimolar amounts replace CMK-1, double-walled carbon nanotubes The inner diameter is 0.7nm and the outer diameter is 1.1nm. The prepared electrode and metal sodium were used to form a sodium-tellurium battery for testing. The discharge capacity of the first cycle was 525mAh / g, and after 40 cycles, the capacity could be maintained at 380mAh / g.

[0075] 3-4a Assembly of Na-ion battery

[0076] The only difference from 1-4a is that the tellurium electrode material obtained in Example 3 is used. The measured first-cycle discharge capacity of the battery at 0.1C is 380mAh / g, and the first-cycle discharge capacity at 0.5C is 315mAh / g. After 50 cycles After cycling, the capacity can be maintained at 302mAh / g.

[0077] 3-4b Assembly of Na-ion battery

[0078] The only difference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com