Electrical steel sheet with a layer improving the electrical insulation and method for the production thereof

A technology of electrical steel sheet and electrical insulation, applied in the direction of manufacturing tools, metal material coating process, coating, etc., can solve the problems of electrical steel sheet and its coating not suitable for use, strong corrosion of electrical steel sheet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

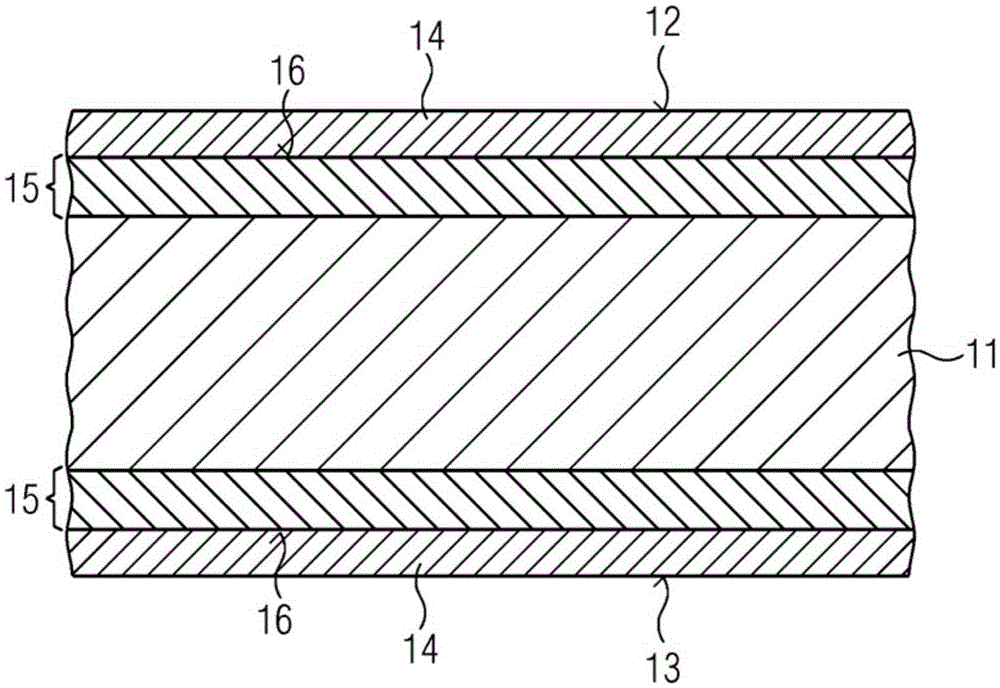

[0017] The figure shows an electrical steel sheet 11 , the upper side 12 and the lower side 13 of which are each provided with a layer 14 of tantalum oxide. This layer 14 rests on a diffusion region 15 which has a common interface 16 with the tantalum oxide layer 12 . After this interface, the concentration of tantalum in the diffusion zone is well over 50%. Towards the interior of the electrical steel sheet 11, the concentration decreases until the concentration is 0% by weight. The boundary between the actual electrical steel sheet 11 and the diffusion zone 15 is therefore not really shown. In this figure, however, regions are shown in which the concentration of tantalum in the structure of the electrical steel sheet 11 exceeds 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com