Dual-compound wear-resisting hammer and manufacturing method thereof

A double-composite, hammer-head technology, applied in grain processing, etc., can solve the problems that it is difficult to form a metallurgical bond between the high-chromium cast iron hammer body and the carbon steel hammer handle, which affects the quality and service life of the hammer head, and the bonding force is not as good as the metallurgical bond. , achieve the effect of overcoming casting defects, reducing cleaning workload, improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

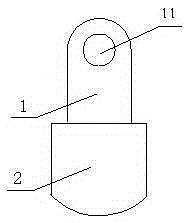

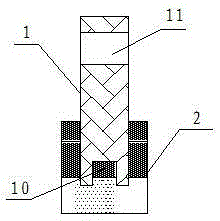

[0030] Embodiment one: see figure 1 with figure 2 , a double-composite wear-resistant hammer head, including a hammer handle 1 and a hammer body 2, one end of the hammer handle 1 is provided with a bottom slot 10, and the other end is provided with a positioning hole 11; the top of the hammer body 2 has an arc surface structure; The hammer handle 1 described above is formed by forging steel, and its material is low-alloy steel. The composition and mass percentage (%) of low-alloy steel: C: 0.3-0.9, Mn: 0.4-1.2, Si: 0.3-1.0, Cr: 0.2-1.2, Mo: 0.1-0.8, Ni: 0.5-6.0, P≤0.05, S≤0.05, and the rest is Fe; the hammer body 2 is composed of two metal liquids of high chromium white cast iron and carbon steel in sequence The hammer head is poured into the sand mold 3 and surrounded by the slot hole 10 at the bottom of the solid hammer handle 1. The hammer head is formed by composite casting. The hammer body 2 and the hammer handle 1 form a metallurgical bond. The composition and mass per...

Embodiment 2

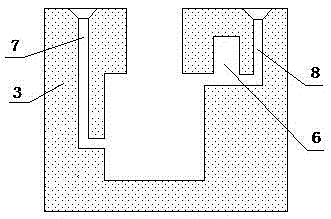

[0031] Embodiment two: see figure 1 , figure 2 , image 3 with Figure 4 , a double-composite wear-resistant hammer head, including a hammer handle 1 and a hammer body 2, one end of the hammer handle 1 is provided with a bottom slot 10, and the other end is provided with a positioning hole 11; the top of the hammer body 2 has an arc surface structure; The hammer handle 1 described above is formed by forging steel, and its material is low-alloy steel. The hammer body 2 is made of high-chromium white cast iron and carbon steel. The hammer head is formed by composite casting around the end of the groove 10 at the bottom of the hammer handle 1, and the hammer body 2 and the hammer handle 1 form a metallurgical bond.

[0032] The manufacturing method of the double-composite wear-resistant hammer head comprises the following steps:

[0033] Step 1: Make casting sand mold 3 according to the structure of the hammer head, select water glass sand to make casting sand mold 3, and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com