New method for removing rare earth element in spent fuel

A spent fuel and organic phase technology, applied in solid separation, flotation, etc., can solve the problems of acid leaching high-level waste liquid, reducing the thermal conductivity of uranium dioxide, etc., and achieve high economic benefits, reduced risks, and low costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

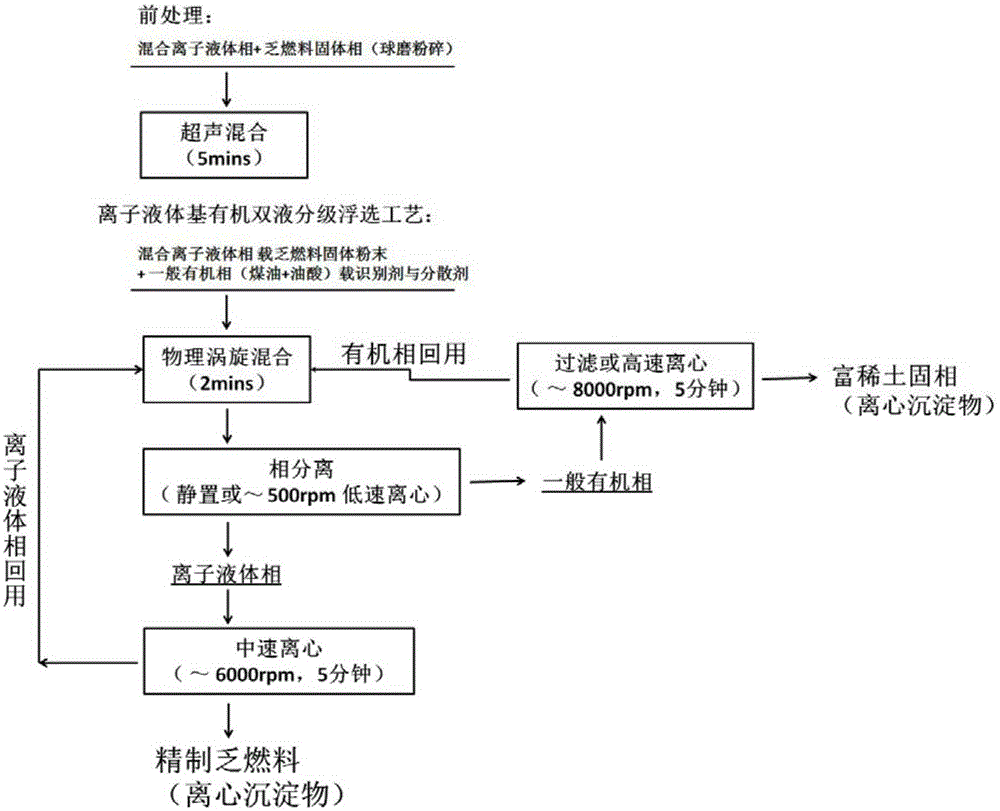

Method used

Image

Examples

Embodiment 1

[0058] Prepare the double organic phase flotation separation system containing ionic liquid of the present invention:

[0059] Select kerosene as the basic solvent phase of the first organic phase, add 100mg / mLCA-12 and PC-88a (rare earth recognition capture reagent and mixed dispersant, the ratio of the two is 1:10) to the kerosene and mix thoroughly to obtain first organic phase;

[0060] Will [C n mim][Tf 2 N] (n is 4) and [C n Py][PF 6 ] (n is 4) were thoroughly mixed at a volume ratio of 1:1 (mL:mL) to obtain a second organic phase.

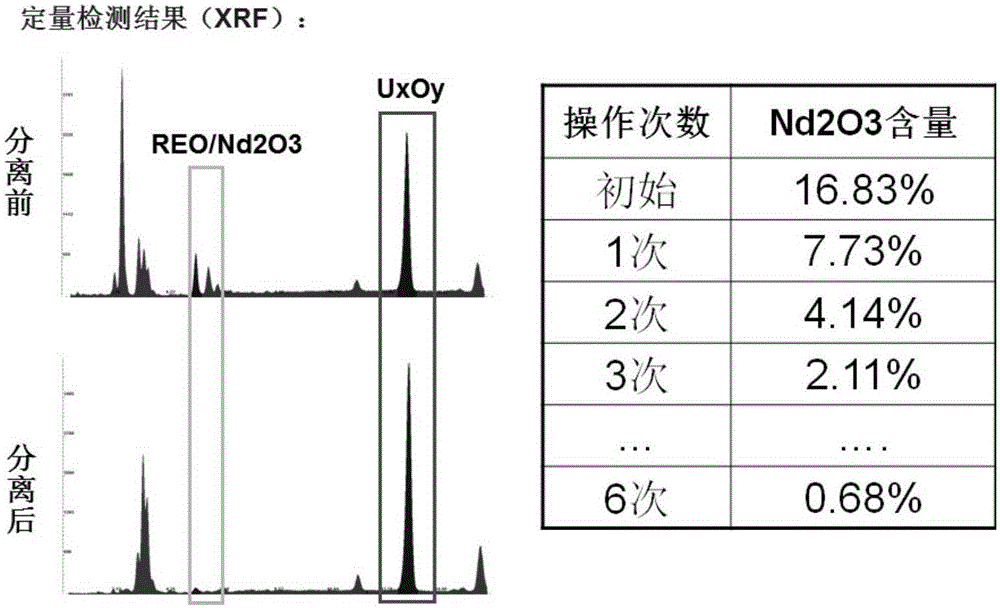

[0061] The first step: 300mg simulated spent fuel (mainly composed of U 3 o 8 , where Nd 2 o 3 The content is 16.83%wt)) into 2mL of the above-mentioned second organic phase, and ultrasonically dispersed, so that the spent fuel is uniformly dispersed in the second organic phase.

[0062] The second step: the second organic phase obtained in the first step is directly mixed with the first organic phase (4mL), or a third phase (such a...

Embodiment 2

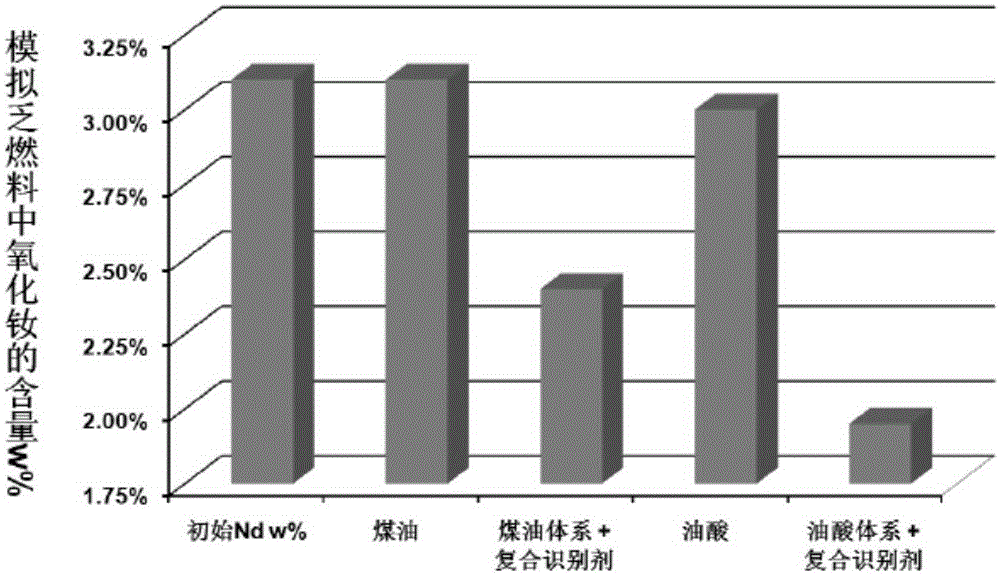

[0069] Adopt the method identical with embodiment 1, just change kerosene into monounsaturated Omega-9 fatty acid (being called for short oleic acid), the result obtained is substantially the same as that of embodiment 1, specifically see image 3 .

Embodiment 3

[0071] Using the same method of operation as in Example 1, it has been verified that U 3 o 8 All solid state separation of La 2 o 3 Effect. In the first phase, oleic acid or sulfonated kerosene was added with 125 mg / mL of P507 and CA-12, and in the second phase, 1:1 [C 4 mim][Tf 2 N] and [C 4 mim][PF 6 ]. U before separation 3 o 8 Middle La 2 o 3 The content of La 2 o 3 The content of La 2 o 3 content down to 1.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com