An improved method for debenzylation and synthesis of d-biotin

A technology of bisbenzyl biotin and biotin, applied in the direction of organic chemistry, etc., can solve the problems of increasing sodium dosage, difficulty and seriousness of workshop production control, and achieves the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

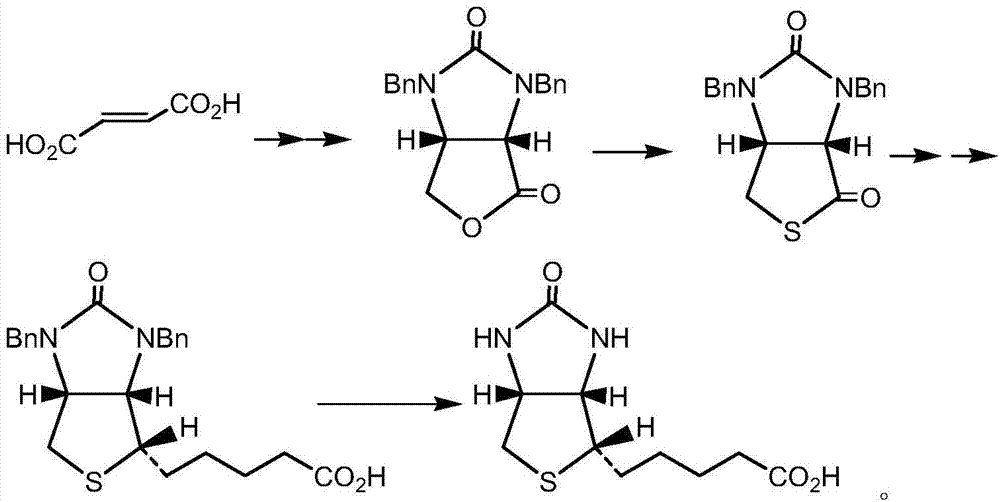

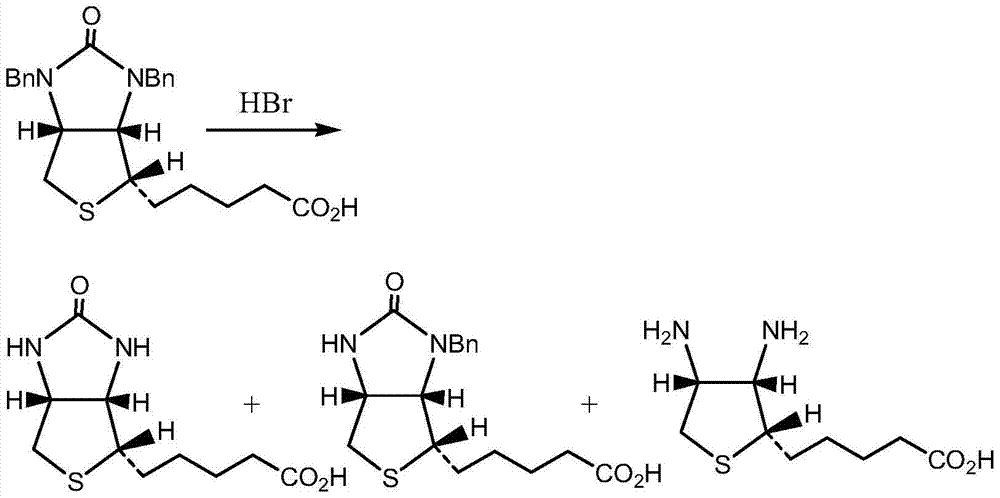

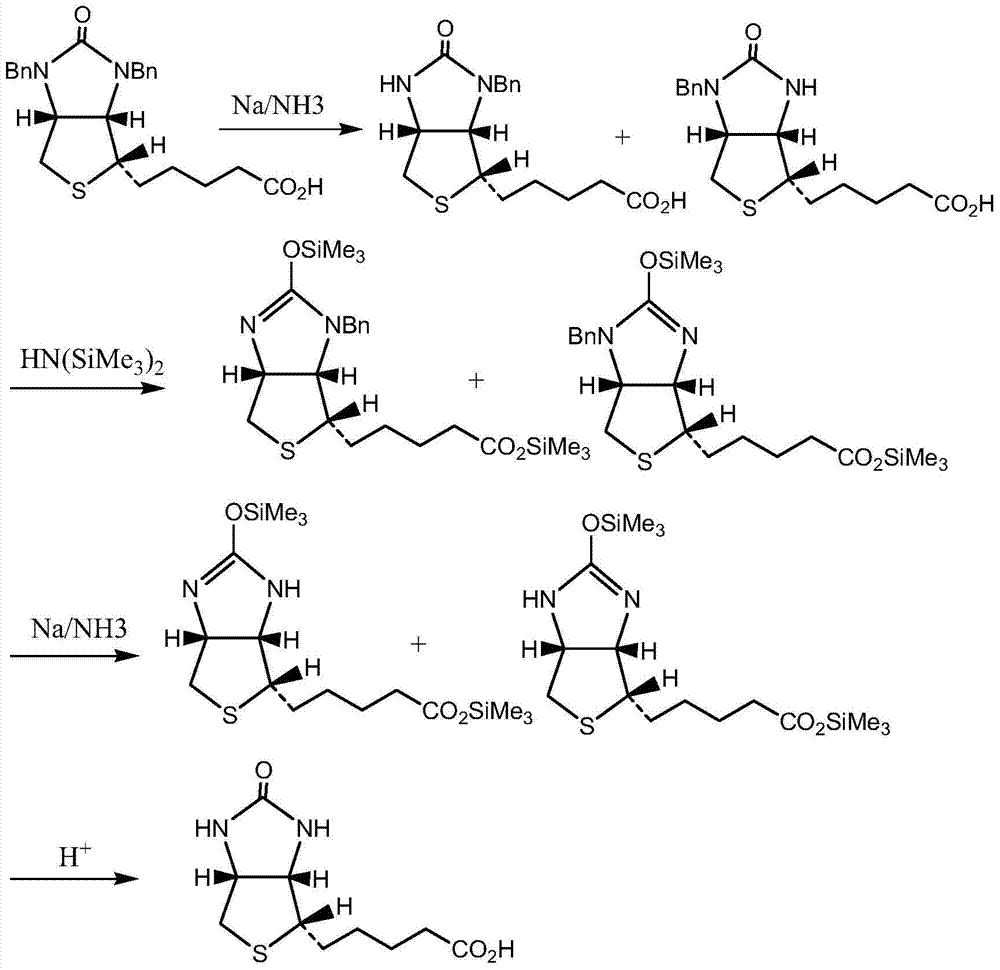

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 The normal complete debenzylation process of the present invention is divided into three steps:

[0033] (1) Preparation of monobenzyl biotin by debenzylation of metal sodium in liquid ammonia

[0034] Take 23g of bisbenzylbiotin (HPLC content 92%, 0.05mol), dissolve it in 50mL of toluene, put it in a 500mL reaction bottle, protect it with nitrogen gas, and cool it with -40°C cryogenic ethanol externally, add liquid ammonia to the reaction bottle 300g, add sodium metal 2.8g (0.12mol) in batches under stirring, after adding sodium metal for the last time, after the color of the reaction solution changes from blue to milky white, after the reaction is complete, add solid ammonium chloride 6.4g, stir for more than one hour, Remove the ice bath, heat in a water bath to volatilize and evaporate the ammonia gas, add 100 mL of water to the residue, adjust the pH value to 2-4 with hydrochloric acid, and precipitate a solid. 16.5 g was obtained by drying, and the c...

Embodiment 2

[0040] Example 2 In the first step, the amount of sodium metal is more

[0041] (1) Preparation of monobenzyl biotin and biotin mixture by debenzylation of metal sodium in liquid ammonia

[0042] Take 23g of bisbenzylbiotin (HPLC content 92%, 0.05mol), dissolve it in 50mL of toluene, put it in a 500mL reaction bottle, protect it with nitrogen gas, and cool it with -40°C cryogenic ethanol externally, add liquid ammonia to the reaction bottle 300g, add sodium metal 4.2 (0.18mol) g in batches under stirring, after adding sodium metal for the last time, after the color of the reaction solution changes from blue to milky white, after the reaction is complete, add solid ammonium chloride 9.6g, stir for more than one hour, Remove the ice bath, heat in a water bath to volatilize and evaporate the ammonia gas, add 100 mL of water to the residue, adjust the pH value to 2-4 with hydrochloric acid, and precipitate a solid. Dry to obtain 15.8 g, the content of biotin detected by HPLC is 1...

Embodiment 3

[0048] Embodiment 3 In the first step, the sodium metal consumption is less

[0049] (1) Preparation of monobenzyl biotin by debenzylation of metal sodium in liquid ammonia

[0050] Take 23g of bisbenzylbiotin (HPLC content 92%, 0.05mol), dissolve it in 50mL of toluene, put it in a 500mL reaction bottle, protect it with nitrogen gas, and cool it with -40°C cryogenic ethanol externally, add liquid ammonia to the reaction bottle 300g, add sodium metal 2.3g (0.1mol) in batches under stirring, after adding sodium metal for the last time, after the color of the reaction solution changes from blue to milky white, the reaction is complete, add solid ammonium chloride 9.6g, stir for more than one hour, Remove the ice bath, heat in a water bath to volatilize and evaporate the ammonia gas, add 100 mL of water to the residue, adjust the pH value to 2-4 with hydrochloric acid, and precipitate a solid. 16.8 g was obtained by drying, the content of dibenzyl biotin was 5.2% and the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com