Method for preparing PbO, PbSO4 and PbO2 from lead plaster of waste lead storage battery through separation

A technology of waste lead storage battery and lead monoxide, which is applied in the field of recycling and utilization of lead resources of waste lead storage batteries and comprehensive utilization of lead resources in waste lead storage batteries, can solve the problems of difficulty in completely restraining, consumption of chemical reagents, and high energy consumption, and achieves the Reduce the effect of material handling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

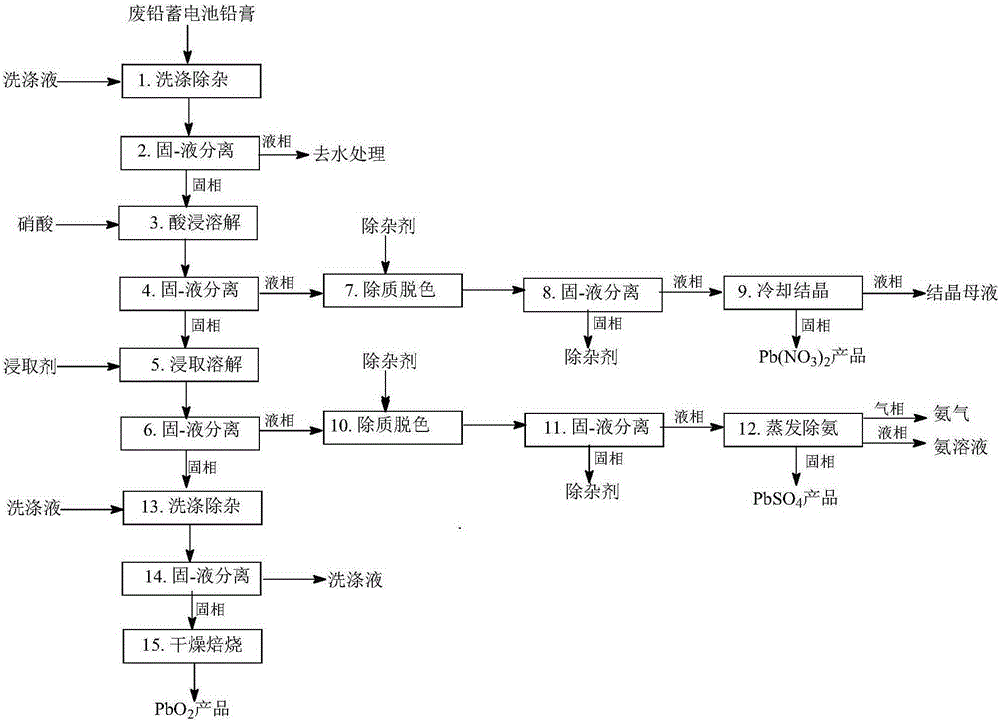

[0114] Such as figure 1 Shown, a waste lead battery lead paste separation preparation of PbO, PbSO 4 , PbO 2 The process method, especially the PbO, PbSO 4 , PbO 2 Lead paste is used as raw material, and PbO and PbSO are prepared by nitric acid dissolution, ammonia leaching, separation and refining, and solid-liquid separation coupling technology. 4 , PbO 2 product. First, nitric acid reacts with PbO to generate Pb(NO 3 ) 2 solution, further separated to obtain PbO; then, using NH 3 ·H 2 O-(NH 4 ) SO 4 Leach PbSO 4 solution, obtained by leaching the PbSO 4 The solution was further separated to obtain PbSO 4 ; Finally, the PbO obtained by solid-liquid separation 2 The solid phase material is further refined and separated to obtain PbO 2 product. Obtained PbO, PbSO 4 , PbO 2 The product is directly used as the raw material for preparing the electrode active material of the lead storage battery, so as to realize the recycling and utilization of the lead paste of...

Embodiment 2

[0131] Such as figure 1 Shown, a waste lead battery lead paste separation preparation of PbO, PbSO 4 , PbO 2 The process method, especially the PbO, PbSO 4 , PbO 2 Lead paste is used as raw material, and PbO and PbSO are prepared by nitric acid dissolution, ammonia leaching, separation and refining, and solid-liquid separation coupling technology. 4 , PbO 2 product. First, nitric acid reacts with PbO to generate Pb(NO 3 ) 2 solution, further separated to obtain PbO; then, using NH 3 .H 2 O-(NH 4 ) SO 4 Leach PbSO 4 solution, obtained by leaching the PbSO 4 The solution was further separated to obtain PbSO 4 ; Finally, the PbO obtained by solid-liquid separation 2 The solid phase material is further refined and separated to obtain PbO 2 product. Obtained PbO, PbSO 4 , PbO 2 The product is directly used as the raw material for preparing the electrode active material of the lead storage battery, so as to realize the recycling and utilization of the lead paste of...

Embodiment 3

[0148] Such as figure 1 Shown, a waste lead battery lead paste separation preparation of PbO, PbSO 4 , PbO 2 The process method, especially the PbO, PbSO 4 , PbO 2 Lead paste is used as raw material, and PbO and PbSO are prepared by nitric acid dissolution, ammonia leaching, separation and refining, and solid-liquid separation coupling technology. 4 , PbO 2 product. First, nitric acid reacts with PbO to generate Pb(NO 3 ) 2 solution, further separated to obtain PbO; then, using NH 3 .H 2 O-(NH 4 ) SO 4 Leach PbSO 4 solution, obtained by leaching the PbSO 4 The solution was further separated to obtain PbSO 4 ; Finally, the PbO obtained by solid-liquid separation 2 The solid phase material is further refined and separated to obtain PbO 2 product. Obtained PbO, PbSO 4 , PbO 2 The product is directly used as the raw material for preparing the electrode active material of the lead storage battery, so as to realize the recycling and utilization of the lead paste of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com