Ge-doped Mg2Si-base thermoelectric film and preparation method thereof

A thermoelectric thin film, power supply technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of low efficiency, cumbersome process, poor controllability, etc., to reduce costs, simplify the preparation process, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

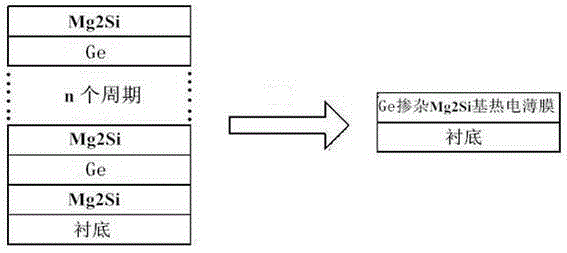

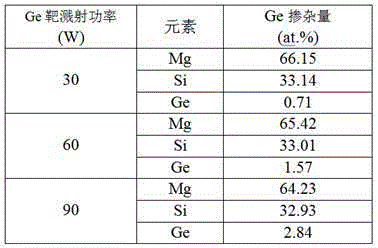

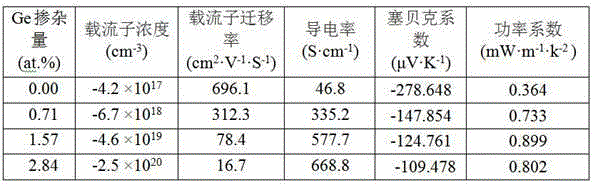

[0022] The magnetron sputtering deposition method is used to carry out double-target cyclic sputtering, in which, one target is placed on Mg 2 For the fourth target, the power supply is radio frequency power supply; for the other target position, a simple target is placed, and the power supply is DC power supply. Coating a layer of Mg on the substrate first 2 Si, followed by a thin layer of Ge, followed by a layer of Mg 2 Si; so many times, so as to prepare a thin film with a laminated structure, and finally use vacuum annealing to obtain Ge-doped Mg 2 Si-based thermoelectric thin film. Before sputtering, use acetone, alcohol and other organic solvents to ultrasonically clean the glass slides for 15 minutes each; vacuumize to 3.5×10 -4 Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 0.5Pa; Mg 2 The RF sputtering power of the Si target is 120W, the DC sputtering power of the Ge target is 30W; the cycle is 12 ti...

Embodiment 2

[0024] The magnetron sputtering deposition method is used to carry out double-target cyclic sputtering, in which, one target is placed on Mg 2 For the fourth target, the power supply is radio frequency power supply; for the other target position, a simple target is placed, and the power supply is DC power supply. Coating a layer of Mg on the substrate first 2 Si, followed by a thin layer of Ge, followed by a layer of Mg 2 Si; so many times, so as to prepare a thin film with a laminated structure, and finally use vacuum annealing to obtain Ge-doped Mg 2 Si-based thermoelectric thin film. Before sputtering, use acetone, alcohol and other organic solvents to ultrasonically clean the glass slides for 15 minutes each; vacuumize to 3.5×10 -4 Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 0.5Pa; Mg 2The RF sputtering power of the Si target is 120W, the DC sputtering power of the Ge target is 60W; the cycle is 12 tim...

Embodiment 3

[0026] The magnetron sputtering deposition method is used to carry out double-target cyclic sputtering, in which, one target is placed on Mg 2 For the fourth target, the power supply is radio frequency power supply; for the other target position, a simple target is placed, and the power supply is DC power supply. Coating a layer of Mg on the substrate first 2 Si, followed by a thin layer of Ge, followed by a layer of Mg 2 Si; so many times, so as to prepare a thin film with a laminated structure, and finally use vacuum annealing to obtain Ge-doped Mg 2 Si-based thermoelectric thin film. Before sputtering, use acetone, alcohol and other organic solvents to ultrasonically clean the glass slides for 15 minutes each; vacuumize to 3.5×10 -4 Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 0.5Pa; Mg 2 The RF sputtering power of Si target is 120W, the DC sputtering power of Ge target is 90W; the cycle is 12 times, Ge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com