Method for restraining secondary electron emission by directly depositing nano-graphene

A technology of secondary electron emission and nano-graphene, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of complex process, poor stability of electron emission suppression, etc., and achieve high process stability, The effect of reducing the secondary electron emission coefficient and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

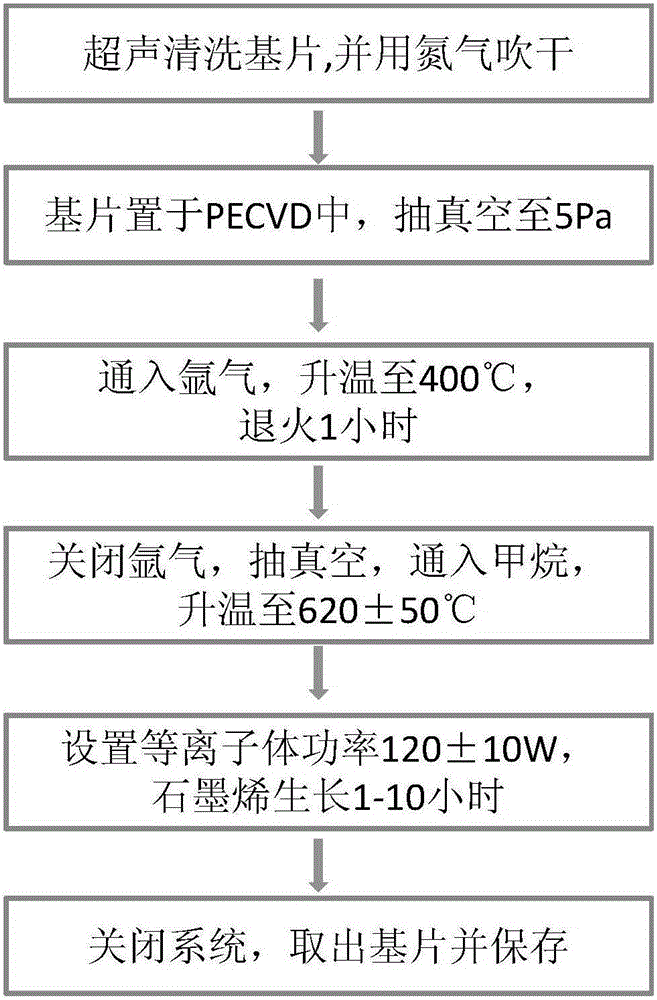

[0044] The nano-graphene film is directly grown on the silver and copper substrates by plasma-enhanced chemical vapor deposition, so as to reduce the secondary electron emission coefficient. The method specifically includes the following steps:

[0045](1) The silver and copper substrates with a length, width and thickness of 15.0mm×12.0mm×0.3mm were ultrasonically cleaned with acetone and alcohol for 30 minutes, respectively, to remove the surface adsorption of the substrate, and blow dry with nitrogen;

[0046] (2) Place the substrate in a remote plasma-enhanced chemical vapor deposition system (PECVD), turn on the mechanical pump, and evacuate to 5Pa, and then keep the vacuum mechanical pump working normally;

[0047] (3) Argon gas with a flow rate of 50 sccm is introduced, the temperature is slowly raised from room temperature to 400° C. over 20 minutes, and annealed at 400° C. for 1 hour;

[0048] (4) Turn off the argon gas, evacuate to below 5Pa, introduce 30sccm methan...

Embodiment 2

[0053] The concrete method of growing nano-graphene film on silver, copper substrate is the same as embodiment 1, and difference is that the control graphene growth time is 10 hours.

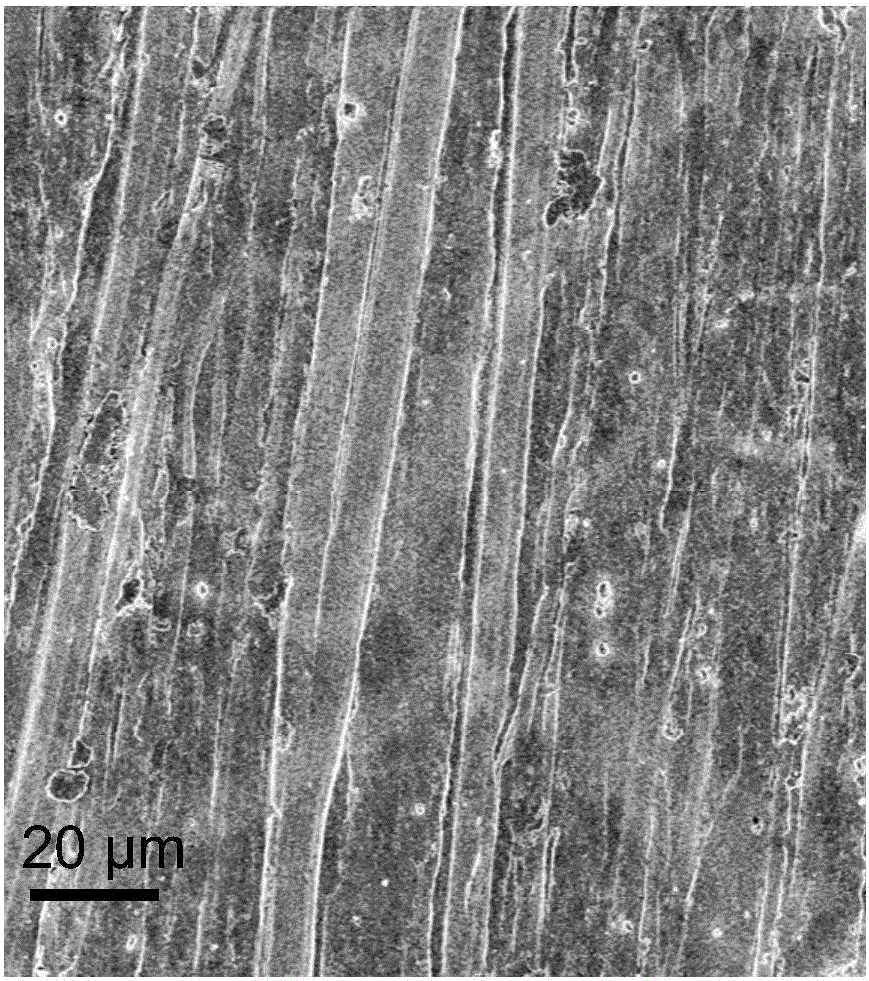

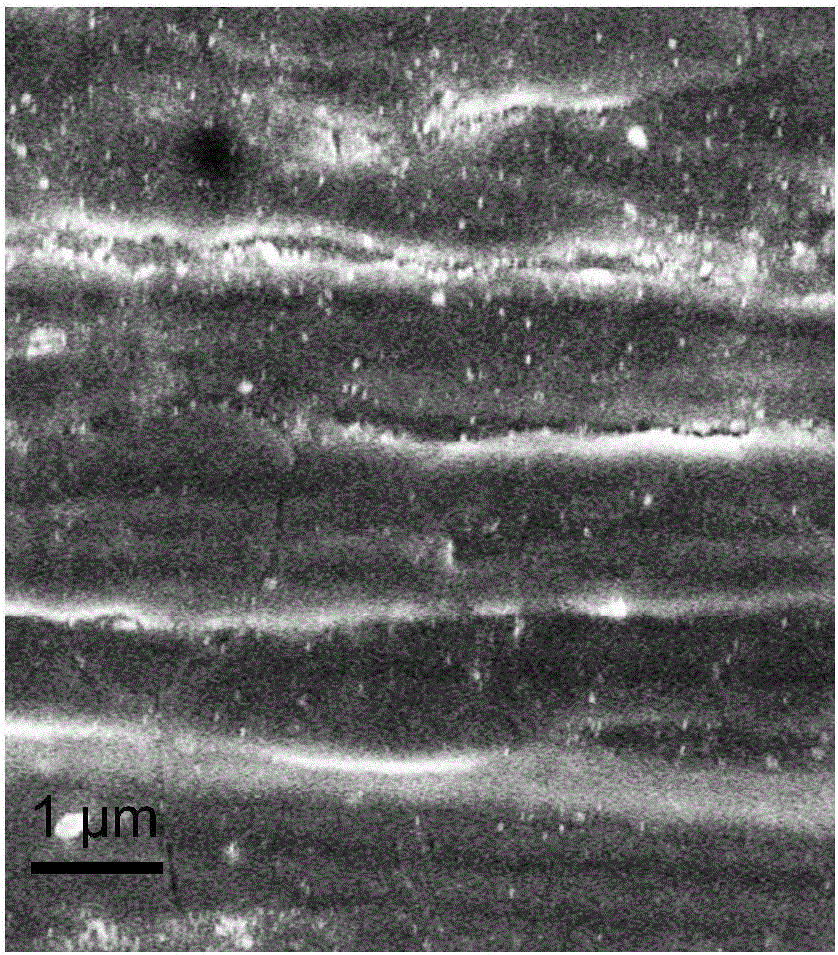

[0054] In the experiment, the secondary electron emission coefficient of the substrate is studied by the current method. The measured secondary electron emission coefficient of the metal copper substrate is 2.16-2.39, and the secondary electron emission coefficient of the silver substrate is 1.97-2.13. The natural graphite material and high orientation The secondary electron emission coefficient of pyrolytic graphite (HOPG) is about 1.28-1.32. Control the graphene growth time for 10 hours, after the nano-graphene material grows on the surface of the copper substrate, its secondary electron emission coefficient drops to 1.04, and the drop can reach 55%. When the secondary electron emission coefficient is 1, the first incident energy point is from 40eV increased to 270eV. After growing nanographe...

Embodiment 3

[0056] The specific method of growing nano-graphene film on copper substrate is the same as embodiment 1, the difference is that the control of graphene growth time is 1-10 hour change.

[0057] With different growth times, the growth thickness of graphene on the substrate surface is different, and its ability to inhibit secondary electron emission is also different. The longer the life time, the greater the thickness of the surface nano-graphene. The graphene growth time on the copper substrate corresponds to the secondary electron emission coefficient as follows: Figure 5 As shown, the experimental results show that different secondary electron emission suppression effects can be achieved by controlling the growth time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com