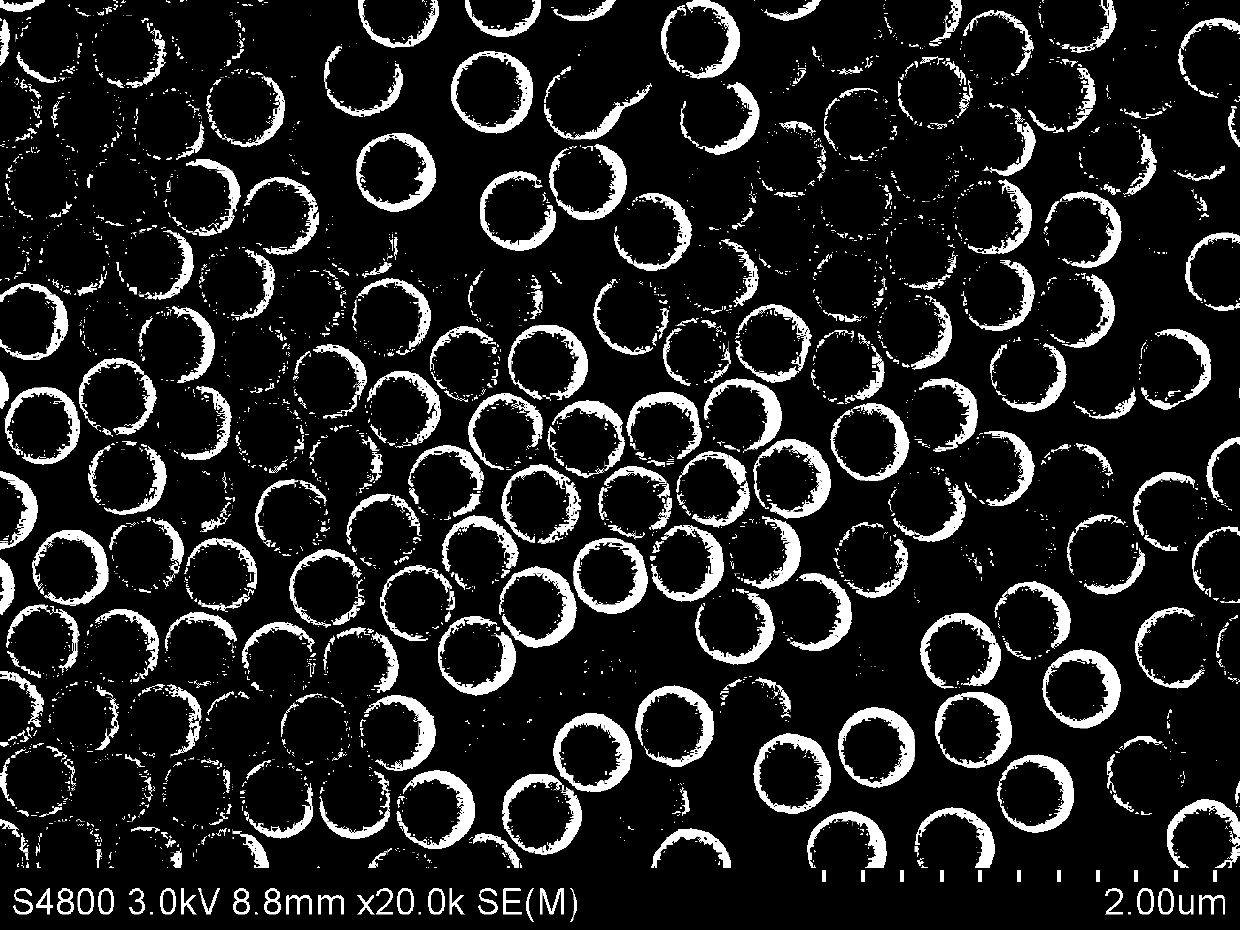

Method for constructing silver film trap structure on metal surface using ps microspheres as template

A silver film trap, metal surface technology, applied in the process, microstructure technology, microstructure device and other directions for producing decorative surface effects, can solve the problem that the size and distribution uniformity of nanopore arrays cannot be well controlled, and cannot be very well controlled. It is easy to control the size of the nanopore array structure and the uncontrollable etching process, so as to achieve the effect of easy mass production, lower secondary electron emission coefficient and strong repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Weigh PS microspheres, add them into anhydrous ethanol-water mixed solution, and obtain PS microsphere dispersion after ultrasonic dispersion for 30 minutes; then, take two metal samples and fix them in a 40×25mm weighing bottle , add the prepared PS microsphere dispersion to just submerge the sample; finally, place the whole device in an oven until the liquid evaporates to dryness, take out the sample, rinse it with distilled water and dry it at 100°C to obtain the PS microspheres loaded on the surface of samples.

[0042] In step one:

[0043] The diameter of PS microspheres is 500nm, and the mass concentration of PS microsphere dispersion is 0.01%%;

[0044] The volume ratio of absolute ethanol to deionized water in the absolute ethanol-water mixed solution is 3:7;

[0045] The size of the metal sample is 24×12×1mm, and the two samples are butted along the side of 12mm, and they are 90°, and the angle is fixed in a weighing bottle of 40×25mm;

[0046] The ...

Embodiment 2

[0053] Step 1: Weigh PS microspheres, add them into anhydrous ethanol-water mixed solution, and obtain PS microsphere dispersion after ultrasonic dispersion for 30 minutes; then, take two metal samples and fix them in a 40×25mm weighing bottle , add the prepared PS microsphere dispersion to just submerge the sample; finally, place the whole device in an oven until the liquid evaporates to dryness, take out the sample, rinse it with distilled water and dry it at 100°C to obtain the PS microspheres loaded on the surface of samples.

[0054] In step one:

[0055] The diameter of PS microspheres is 500nm, and the mass concentration of PS microsphere dispersion is 0.03%;

[0056] The volume ratio of absolute ethanol to deionized water in the absolute ethanol-water mixed solution is 7:3;

[0057] The size of the metal sample is 24×12×1mm, and the two samples are butted along the side of 12mm, and they are 90°, and the angle is fixed in a weighing bottle of 40×25mm;

[0058] The e...

Embodiment 3

[0065] Step 1: Weigh PS microspheres, add them into anhydrous ethanol-water mixed solution, and obtain PS microsphere dispersion after ultrasonic dispersion for 30 minutes; then, take two metal samples and fix them in a 40×25mm weighing bottle , add the prepared PS microsphere dispersion to just submerge the sample; finally, place the whole device in an oven until the liquid evaporates to dryness, take out the sample, rinse it with distilled water and dry it at 100°C to obtain the PS microspheres loaded on the surface of samples.

[0066] In step one:

[0067] The diameter of PS microspheres is 500nm, and the mass concentration of PS microsphere dispersion is 0.05%;

[0068] The volume ratio of absolute ethanol to deionized water in the absolute ethanol-water mixed solution is 10:0, that is, no deionized water is added, only absolute ethanol is added;

[0069] The size of the metal sample is 24×12×1mm, and the two samples are butted along the side of 12mm, and they are 90°, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com