Drying method for pometia pinnata solid wood floor blanks

A drying method and technology of floor slabs, applied in the direction of static material dryers, drying gas arrangement, local mixing dryers, etc., can solve the problems of ineffective killing of wood insect pests, harmful organisms spreading, troubles for consumers and producers, etc. , to achieve the effects of small drying residual stress, uniform moisture distribution, and improved product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] To dry longan floor blanks with a length of 940mm, a width of 140mm, a thickness of 25mm, and an initial moisture content of 59%, the final moisture content of drying is required to be 8%-10%.

[0016] The specific drying process includes the following steps:

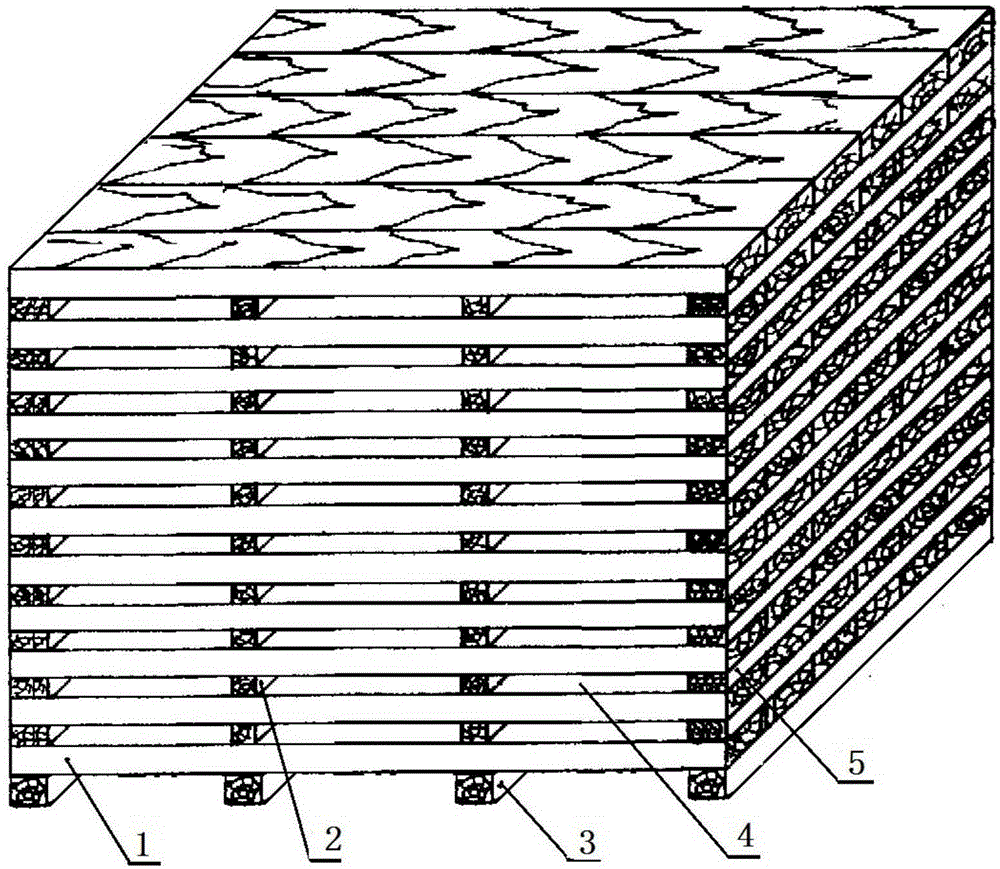

[0017] 1) First use the internal spacer 2 with a length of 1000mm and a cross-section of 15×20mm and the side spacer 5 of 15×40mm to put 1 yard of the longan floor blank into a material pile with a width of 1000mm, wherein the cross-section is 15× 40mm edge spacer bar 5 is used for the end of the material pile. The materials are stacked into a material pile with a length of 940mm, a width of 1000mm and a height of 1200mm, such as figure 1 .

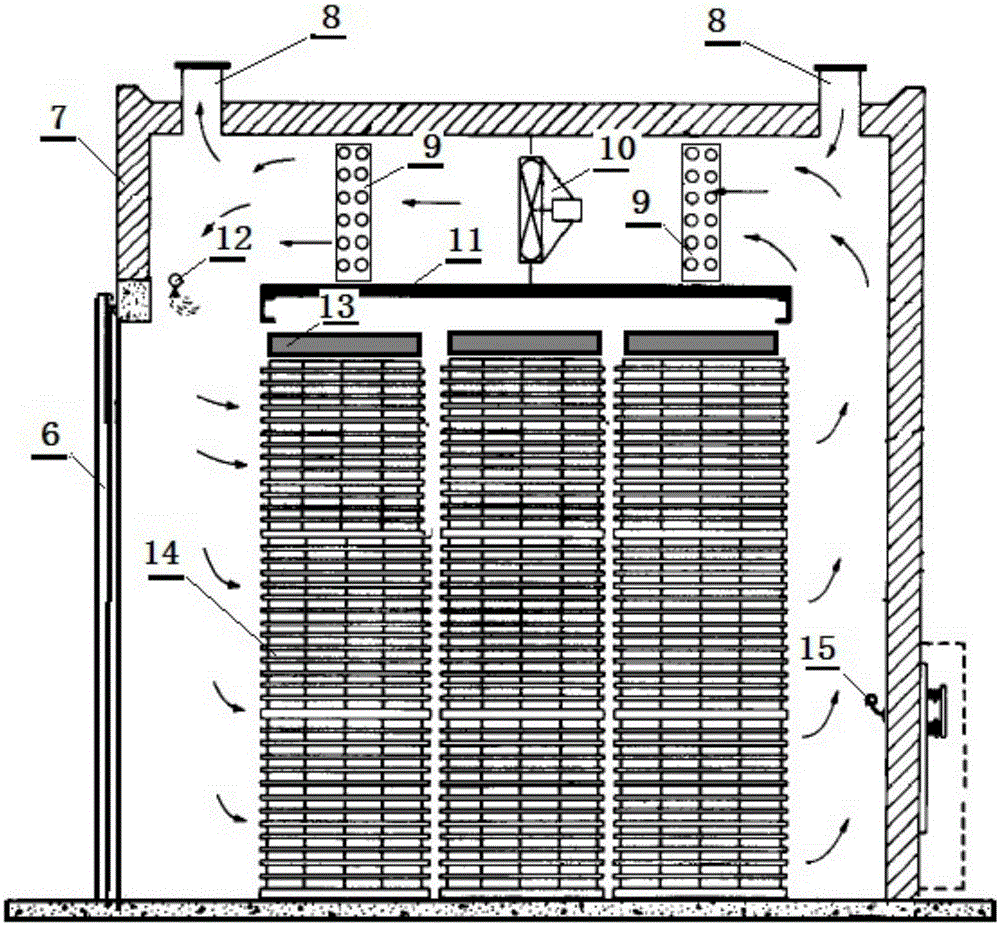

[0018] 2) place the pile of materials 14 figure 2 In the drying kiln 7 shown, and the top of the pile is used 300kg / m 2 Heap top weight 13 (as cement block, cast iron block etc.). Close the door 6, start the drying process afterwards: open the circulation fan 11, make ...

Embodiment 2

[0022] Drying the longan floor blank with a length of 1200mm, a width of 110mm, a thickness of 50mm, and a moisture content of 45% requires a final moisture content of 6-8%.

[0023] 1) First use the internal spacer 2 with a length of 1000mm and a cross-section of 15×20mm and the edge spacer 5 of 15×50mm to put 1 yard of the longan floor blank into a material pile with a width of 1000mm, wherein the cross-section is 15× 40mm edge spacer bar 5 is used for the end of the material pile. The materials are stacked into a material pile with a length of 940mm, a width of 1000mm and a height of 1200mm, such as figure 1 .

[0024] 2) place the pile of materials 14 figure 2 In the drying kiln 7 shown, and the top of the pile is used 500kg / m 2 Heap top weight 13 (as cement block, cast iron block etc.). Close the door 6, start the drying process afterwards: open the circulation fan 11, make the moist air in the drying kiln pass through the air passage in the material pile 14 with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com