Method for directly determining aluminum content in aluminum-niobium alloy

A niobium alloy and aluminum content technology, which is applied in the field of chemical analysis and detection of cemented carbide, can solve the problems affecting the production efficiency and profit of enterprises, and achieve the effect of reliable quality reference, reducing loss and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

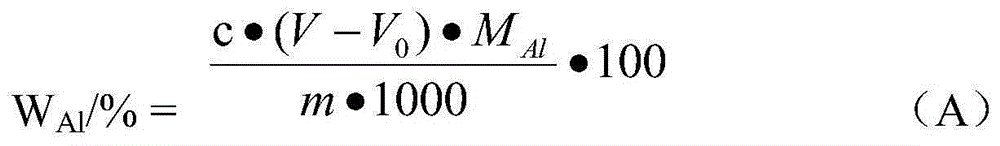

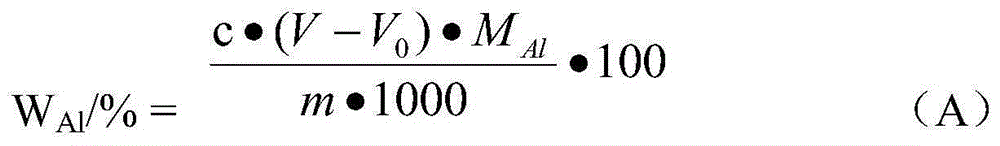

Method used

Image

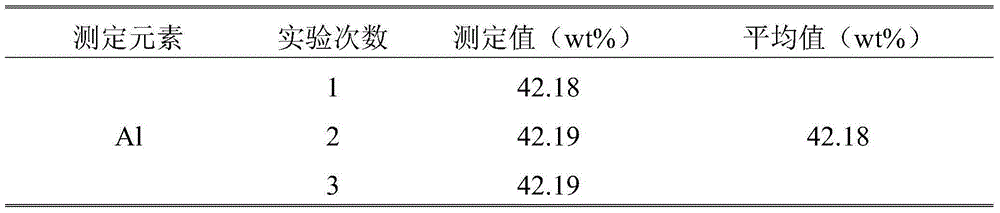

Examples

Embodiment 1

[0046] A method for directly measuring aluminum content in an aluminum-niobium alloy, the method steps are as follows:

[0047] (1) Crushing the aluminum-niobium alloy to be measured, passing through a 200-mesh stainless steel standard sieve after crushing, and then using the heap-cone quartering method to shrink and select samples to obtain a powdered aluminum-niobium alloy sample with a particle size ≥ 200 mesh; accurately weigh Add 0.1000g of a powdered aluminum-niobium alloy sample with a particle size ≥ 200 mesh into the volumetric flask, measure 10mL of sulfuric acid solution and 10mL of nitric acid solution with a measuring cylinder, mix them in the volumetric flask, put them on an electric furnace, heat and boil until the sample is dissolved Completely, take out the volumetric flask and cool it down to room temperature naturally to obtain the solution to be tested;

[0048] The sulfuric acid solution is a solution mixed with analytically pure sulfuric acid and distille...

Embodiment 2

[0075] A method for directly measuring aluminum content in an aluminum-niobium alloy, the method steps are as follows:

[0076] (1) Crushing the aluminum-niobium alloy with a measurement, passing through a 200-mesh stainless steel standard sieve after crushing, and then using the heap-cone quartering method to shrink and select samples to obtain a powdered aluminum-niobium alloy sample with a particle size ≥ 200 mesh; accurately weigh Measure 0.2000g of powdered aluminum-niobium alloy sample with particle size ≥ 200 mesh into the volumetric flask, measure 20mL of sulfuric acid solution and 20mL of nitric acid solution into the volumetric flask with a measuring cylinder, mix them, put them on an electric furnace, heat and boil until the sample Dissolve completely, take out the volumetric flask and cool it down to room temperature naturally to obtain the solution to be tested;

[0077] The sulfuric acid solution is a solution mixed with analytically pure sulfuric acid and distil...

Embodiment 3

[0103] A method for directly measuring aluminum content in an aluminum-niobium alloy, the method steps are as follows:

[0104](1) Crushing the aluminum-niobium alloy with a measurement, passing through a 200-mesh stainless steel standard sieve after crushing, and then using the heap-cone quartering method to shrink and select samples to obtain a powdered aluminum-niobium alloy sample with a particle size ≥ 200 mesh; accurately weigh Measure 0.3000g of powdered aluminum-niobium alloy sample with particle size ≥200 mesh into the volumetric flask, measure 20mL of sulfuric acid solution and 20mL of nitric acid solution with a measuring cylinder, mix them in the volumetric flask, heat and boil on the electric furnace until the sample Dissolve completely, take out the volumetric flask and cool it down to room temperature naturally to obtain the solution to be tested;

[0105] The sulfuric acid solution is a solution mixed with analytically pure sulfuric acid and distilled water at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com