Systems and methods for efficient power generation using a carbon dioxide cycle working fluid

A power generation system and working technology, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of high power cost, high capital cost, low thermal efficiency, etc., and achieve the goal of reducing physical size and capital cost, and reducing construction cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

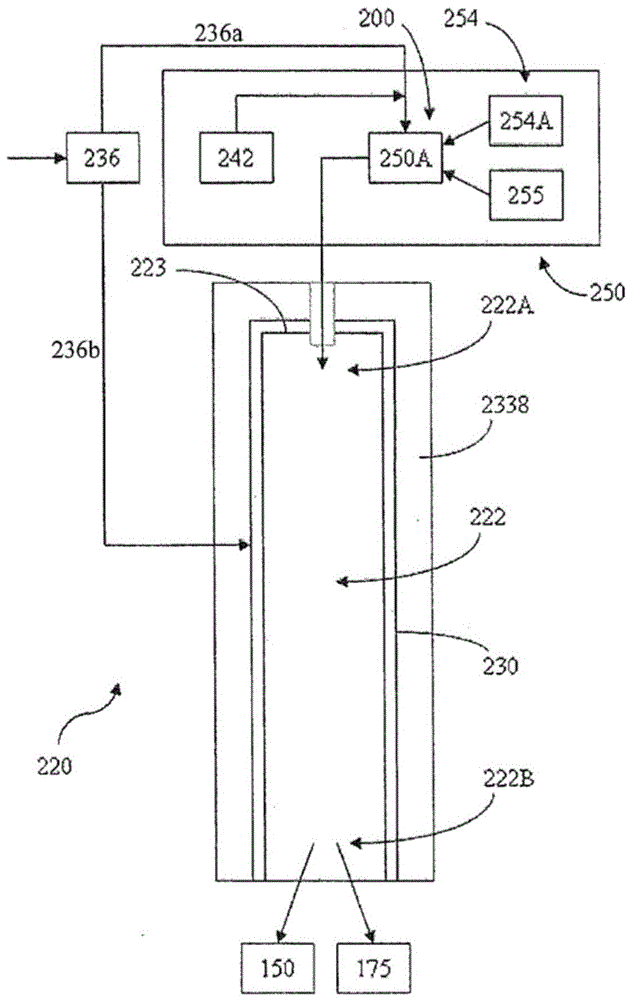

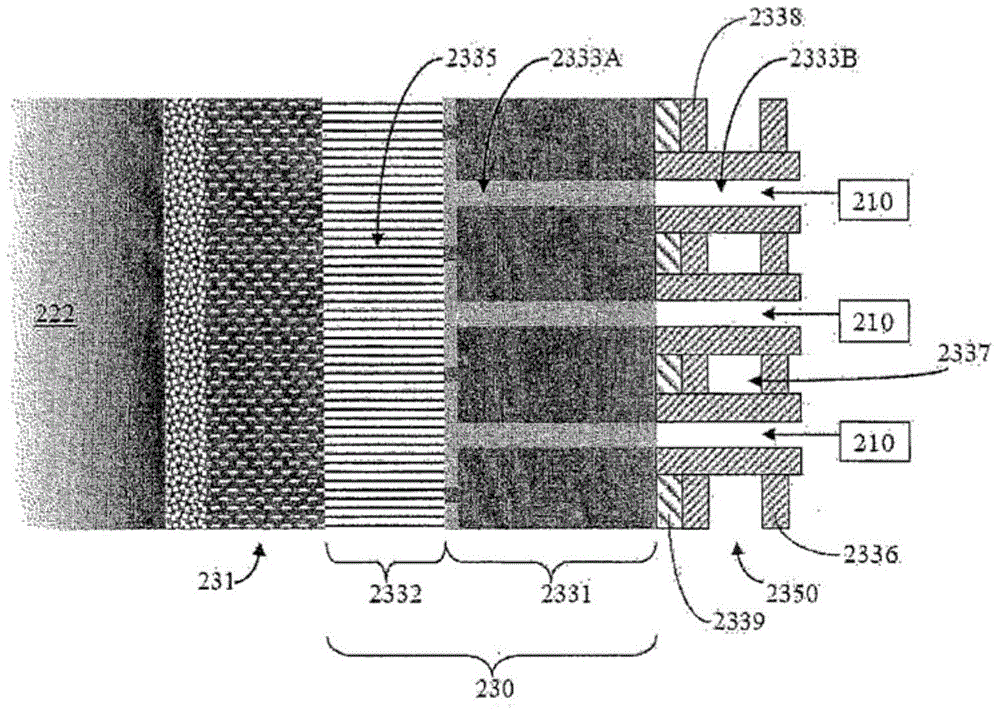

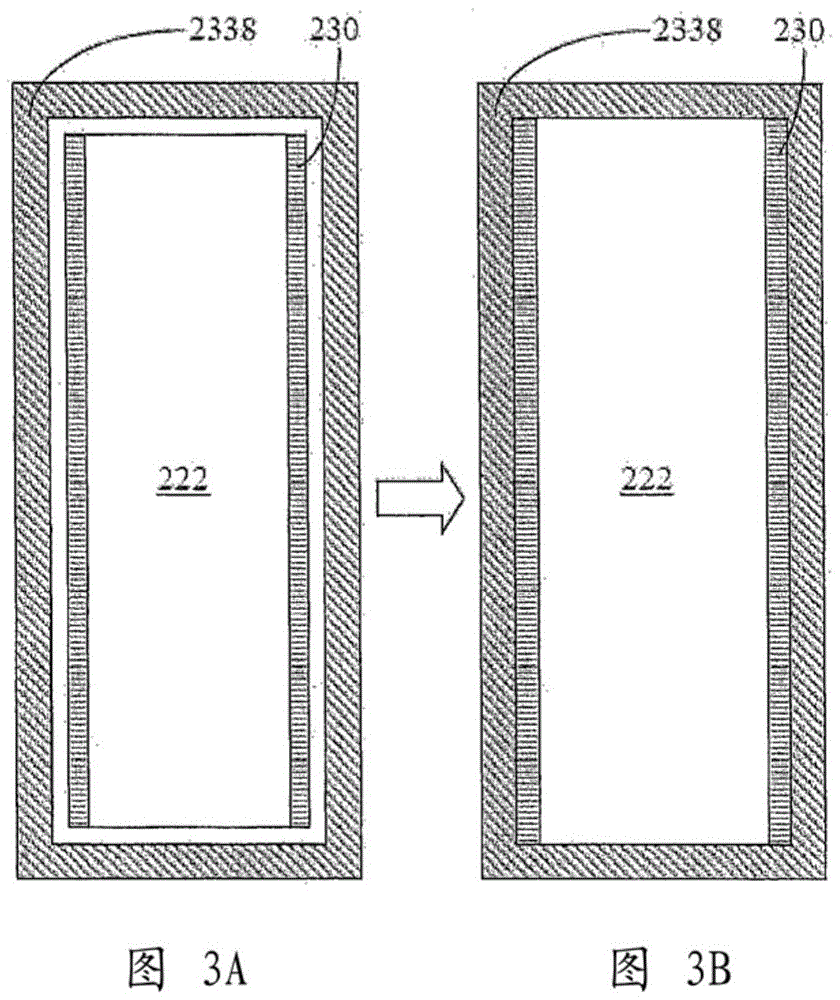

[0281] Example 1 Using recycled CO 2 Systems and methods for power generation by combustion of methane from circulating fluids

[0282] A specific embodiment of the system and method according to the present invention is in Figure 11 in the illustration. The following description uses computer simulations to describe the system for a specific cycle under specific conditions.

[0283] In this model, methane (CH 4 ) fuel stream 254 with recycled CO 2 Circulating fluid stream 236 is combined in mixer 252 at a temperature of 860° C. and a pressure of 30.3 MPa (and thus it is in a supercritical fluid state) before being introduced into evaporatively cooled combustor 220 . The air separation unit 30 is used to provide concentrated O at a temperature of 105 ° C and a pressure of 30.5 MPa 2 242. The air separation unit also generates heat (Q) which is transferred for use in the process. o 2 242 in combustor 220 with methane fuel stream 254 and CO 2 Circulating fluid 236 comb...

Embodiment 2

[0290] Example 2 Using recycled CO 2 System and method for circulating fluid power generation with pulverized coal power plant retrofit

[0291] Another specific embodiment of the system and method according to the present invention is in Figure 12 in the illustration. The following description uses mathematical simulations to describe the system for a specific cycle under specific conditions.

[0292] This model illustrates the ability to retrofit the systems and methods as described herein for conventional pulverized coal fired power plants.

[0293] O at a pressure of 30.5MPa 2 Stream 1056 together with carbonaceous fuel 1055 (e.g., coal-derived gas illustrated by partial oxidation) at a pressure of 30.5 MPa and CO at a pressure of 30.5 MPa 2 Circulating fluid stream 1053 is introduced into transpiration cooled combustor 220 . The O 2 May be received from an air separator or similar device capable of generating heat (Q) that can be transferred for use in the system, s...

Embodiment 3

[0320] Example 3 Using recycled CO 2 System and method for circulating fluid and multiple expansion steps to generate electricity with methane combustion

[0321] Figure 13 A system and method according to an embodiment of the present disclosure is shown that includes two turbines operating in series with two combustors that burn natural gas using pure oxygen as the oxidant to preheat the inlet to each turbine flow. The presence of the second expansion turbine significantly increases the pressure ratio of the overall turbine system while maintaining virtually the same heat load of the recuperator. The described embodiments also benefit from recirculating high pressure CO by feeding externally generated heat (as described herein) into recuperators at temperature levels ranging from about 150°C to 400°C. 2 Increased efficiency provided in logistics. This additional heat source is the heat of adiabatic compression of the main air compressor in the cryogenic air separation pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com