Technology method for re-manufacturing individual hydraulic prop

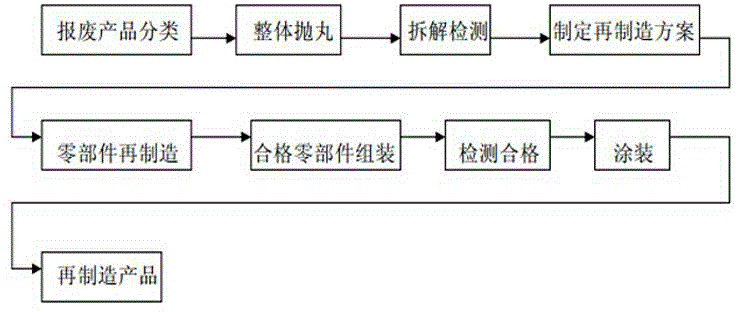

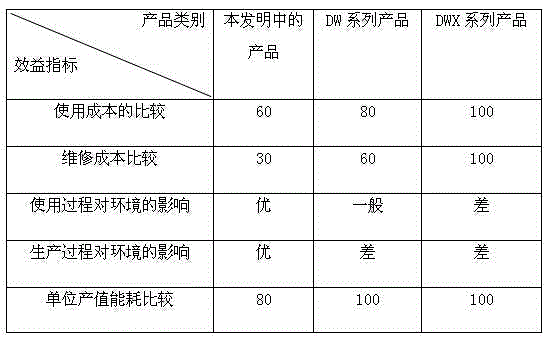

A technology of single hydraulic prop and process technology, which is applied in the direction of prop/bracket, earthwork drilling, mining equipment, etc., and can solve the problems of scrapping and waste of single hydraulic prop for mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

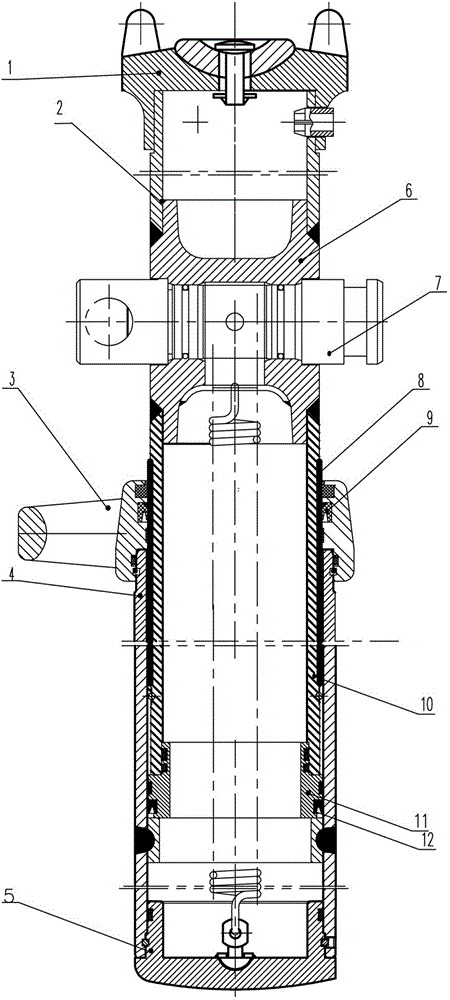

Examples

Embodiment 1

[0051] 3 cleaned live columns, injection molding process, the injection mold is a special mold for live column injection molding, the raw material for injection molding is thermoplastic polyester polyurethane elastomer particles, the hardness is 74D, and the particles are dried before injection molding: drying temperature 95 ℃ , The drying time is 3 hours, the thermoplastic polyurethane elastomer is dehumidified and dried, and the water content is 290ppm (mg / kg); the injection molding parameters are: injection molding pressure: 65kg, flow rate: 25%, temperature: 215°C. After the injection molding is completed, a 4mm injection molding layer is obtained, and the final live column diameter φ96 is obtained by lathe processing, and a qualified live column finished product is obtained.

Embodiment 2

[0053] 3 cleaned live columns, injection molding process, the injection mold is a special mold for live column injection molding, the raw material for injection molding is thermoplastic polyether polyurethane elastomer particles, the hardness is 74D, and the particles are dried before injection molding: drying temperature 90 ℃ , The drying time is 4 hours, the thermoplastic polyurethane elastomer is dehumidified and dried, and the water content is 285ppm (mg / kg); the injection molding parameters are: injection molding pressure: 70kg, flow rate 30%, temperature 230°C. After the injection molding is completed, a 4mm injection molding layer is obtained, and the final live column diameter φ96 is obtained by lathe processing, and a qualified live column finished product is obtained.

Embodiment 3

[0055] 3 cleaned live columns, injection molding process, the injection mold is a special mold for live column injection molding, the injection molding raw material is thermoplastic polyester polyurethane elastomer particles, the hardness is 95A, and the particles are dried before injection molding: drying temperature 95 ℃ , The drying time is 3 hours, the thermoplastic polyurethane elastomer is dehumidified and dried, and the water content is 290ppm (mg / kg); the injection molding parameters are: injection molding pressure: 65kg, flow rate: 25%, temperature: 215°C. After the injection molding is completed, a 4mm injection molding layer is obtained, and the final live column diameter φ96 is obtained by lathe processing, and a qualified live column finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com