Green brick stacking method for pulverized fuel ash pressurizing bricks

A fly ash and adobe technology, applied in the field of adobe stacking, can solve the problems of wasted loading space, high labor intensity, and troublesome operating procedures, and achieve the effects of saving loading space, reducing labor intensity, and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

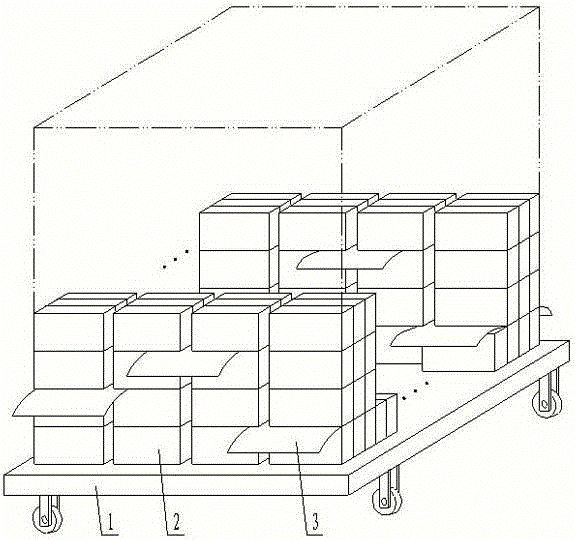

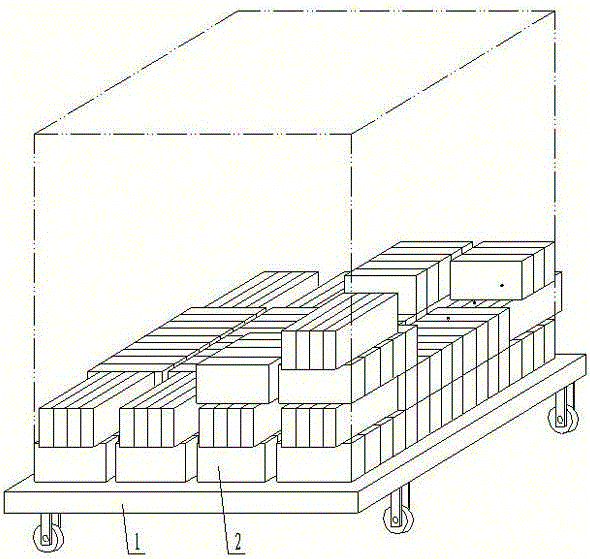

[0019] Such as figure 1 Shown: when the manipulator of the brick making machine (not shown in the figure) automatically grabs four adobes 2 at a time according to the side-standing manner and arranges them on the flatbed carrier 1 in turn until the four rows are full; in each row of adobes 2 on the release paper 3, and then control the manipulator to stack the bricks 2 on the release paper 3 in turn until the second layer of stacking is completed; then lay the release paper 3 on the second layer 2, and repeat the cycle until the second layer is completed. Ten layers of palletizing.

[0020] When there is a bump during the transfer process, the adobe 2 in the middle will not shake back and forth (or the shaking range is small) due to the obstruction of other adobes 2, only the first three to four and the last of each row of brick stacks Three to fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com