Method of quenching up-conversion luminescence

A quenching and fluorophore technology, applied in the field of luminescence, can solve the problems of optical amplifier efficiency decline, affect the performance of materials and devices, reduce energy transfer, etc., and achieve the effect of good application range, unique functions and characteristics, and simple physical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

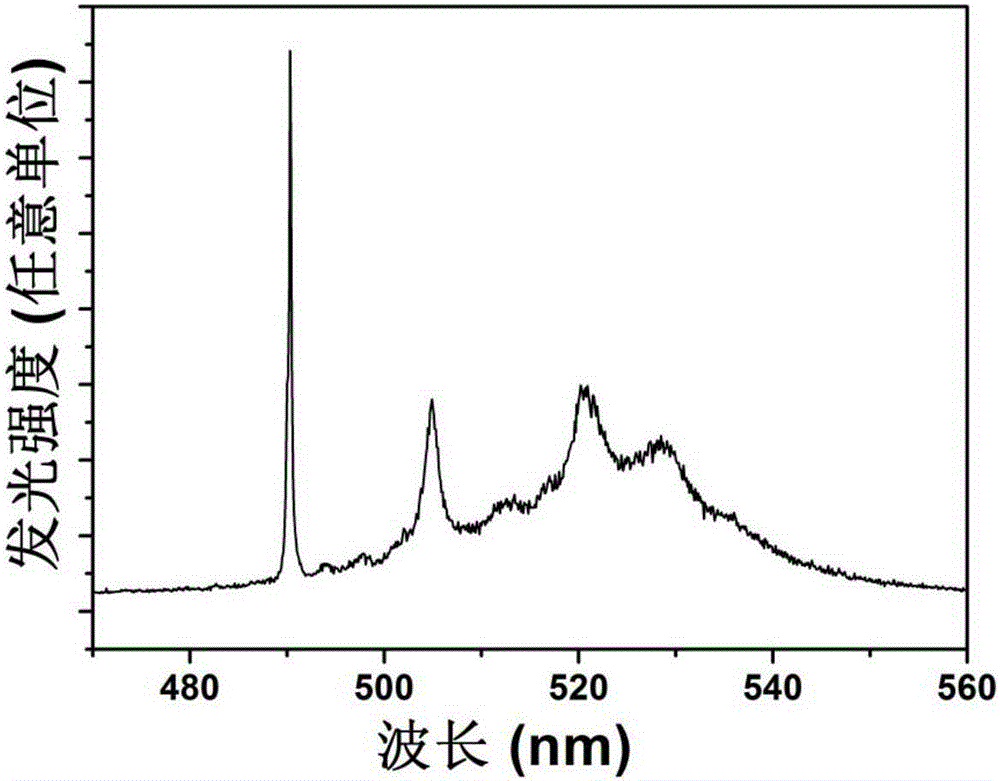

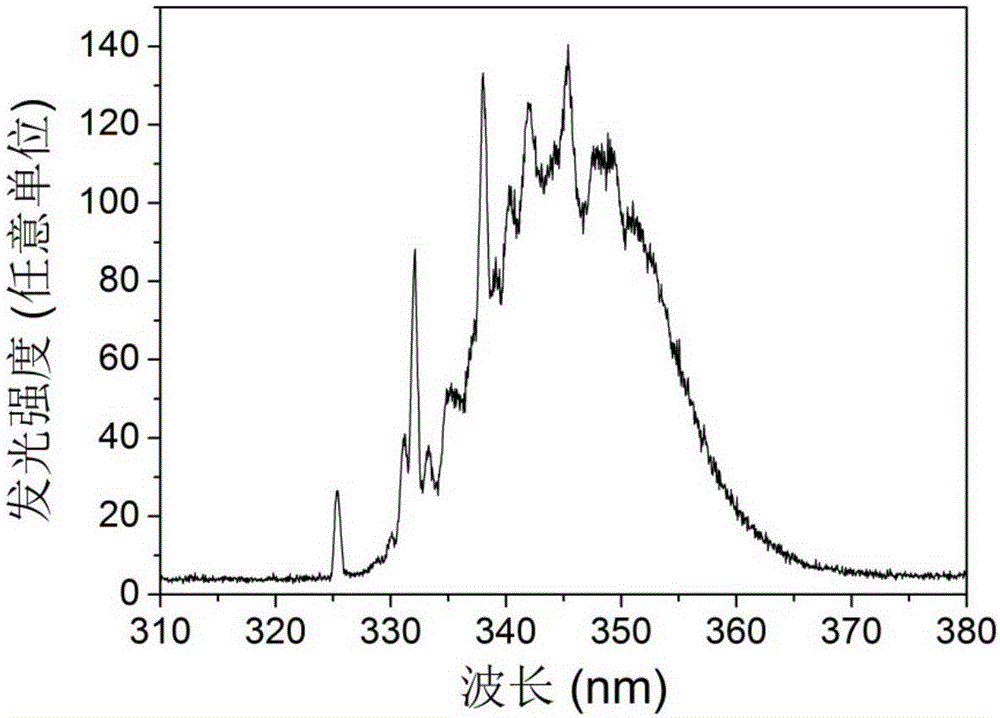

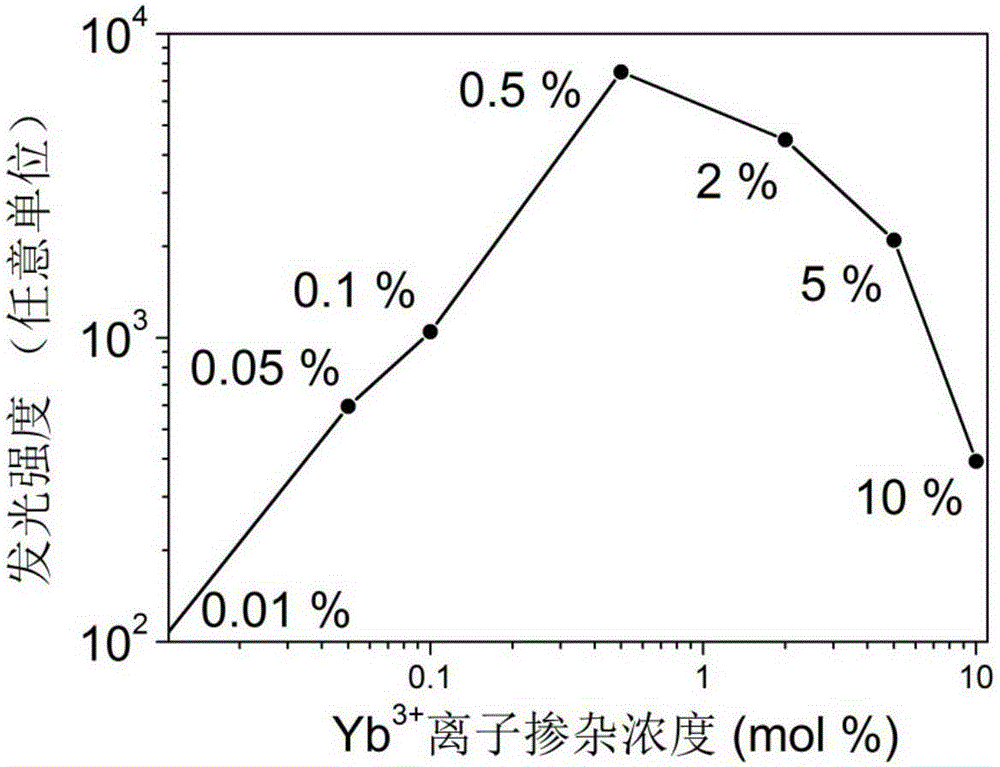

Embodiment 1

[0021] Weigh a certain amount of CaF according to the molar ratio 2 and YbF 3 , fully ground to make it evenly mixed, put it into platinum or other non-corrosive crucibles, place it in a vacuum environment at 1450 ° C for 4 hours, and take it out after naturally cooling to room temperature to obtain a white mixed crystal material. Under the excitation of 980nm near-infrared light, CaF prepared under high temperature conditions 2 :0.5mol%Yb 3+ The mixed crystal material emits bright green fluorescence; spectral analysis shows that the green fluorescence comes from Yb 3+ Cooperative luminescence of ion pairs. As the test temperature decreases, the green cooperation glow becomes stronger and stronger, figure 1 It is the emission spectrum measured at a low temperature of 100K. At a low temperature of 13K, the sample emits ultraviolet cooperative luminescence in the ultraviolet spectral region; spectral analysis shows that the ultraviolet fluorescence comes from Yb 3+ Coopera...

Embodiment 2

[0023] Preparation of Yb by Co-precipitation 3+ (2mol%) and Y 3+ (0,0.5,1,2mol%) co-doped CaF 2 powder. The raw material used in the experiment was Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , Y(NO 3 ) 3 and NH 4 HF 2 . First prepare 0.5mol / L of Yb(NO 3 ) 3 , 0.01mol / L of Y (NO 3 ) 3 , 0.5mol / L Ca(NO 3 ) 2 standard aqueous solution. A certain amount of Yb(NO 3 ) 3 , Y(NO 3 ) 3 and Ca(NO 3 ) 2 The solution was put into a beaker and stirred for 30min, then the solution was added dropwise to NH 4 HF 2 Aqueous solution (15mol / L) was stirred for 1 hour to make it mix uniformly. The stirred mixture was filtered with filter paper, the resulting precipitate was washed with deionized water, dried at 95°C for 12 hours, and calcined at 1200°C for 2 hours to obtain a series of different Y 3+ Doped mole fraction of CaF 2 :Yb 3+ ,Y 3+ sample.

[0024] XRD studies show that the material matrix prepared by the above method is CaF 2 , with a cubic crystal structure. The XRD diff...

Embodiment 3

[0027] Preparation of Yb by Co-precipitation 3+ (1mol%) and Pb 2+ (0,0.3,0.5,0.8,1,2,3,4,6mol%) co-doped CaF 2 powder. The raw material used in the experiment was Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , Pb(NO 3 ) 2 and NH 4 HF 2 . First prepare 0.5mol / L of Yb(NO 3 ) 3 , 0.01mol / L of Pb(NO 3 ) 2 , 0.5mol / L Ca(NO 3 ) 2 standard aqueous solution. A certain amount of Yb(NO 3 ) 3 , Pb(NO 3 ) 2 and Ca(NO 3 ) 2 The solution was put into a beaker and stirred for 30min, then the solution was added dropwise to NH 4 HF 2 Aqueous solution (15mol / L) was stirred for 1 hour to make it mix uniformly. The stirred mixture was filtered with filter paper, the resulting precipitate was washed with deionized water, dried at 95°C for 12 hours, and calcined at 1200°C for 2 hours to obtain a series of different Pb 2+ Doped mole fraction of CaF 2 :Yb 3+ ,Pb 2+ sample.

[0028] Under 980nm light excitation, we measured the CaF 2 :0.5%Pb 2+ and CaF 2 :1%Yb 3+ ,x%Pb 2+ (x=0, 0.3, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com