Front fuel oil purifying device of engine and application of front fuel oil purifying device

An engine and fuel technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve problems such as high cost, damage, clogging of three-way catalytic converters, etc., so as to reduce the generation of carbon deposits, reduce pollution, and reduce excessive exhaust gas. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Tin-antimony alloy adsorption catalytic element

[0035] The raw materials for preparation are solid tin and antimony, which are melted into liquid at a high temperature of 300 degrees, mixed according to the ratio through a 1200 degrees vacuum furnace, and copper accounting for 3% of the mass of tin and antimony is added at the same time. The shape of the grid is an open steel mold, and the liquid Pour on the mold and make a circular outer cylinder and a middle grid shape through cold water cooling. The diameter (outer diameter) of the circle is 26mm, such as Figure 5 , Figure 6 , the tin-antimony alloy catalytic element 5 is a structure in which a tin-antimony alloy mesh is placed horizontally in a circular outer cylinder. There are square meshes 6 on the tin-antimony alloy mesh, and the size of the mesh is 2.5×2.5; the distance between adjacent meshes is mm. The height of the circular outer cylinder is 5mm, and the thickness of the horizontal tin-ant...

Embodiment 2

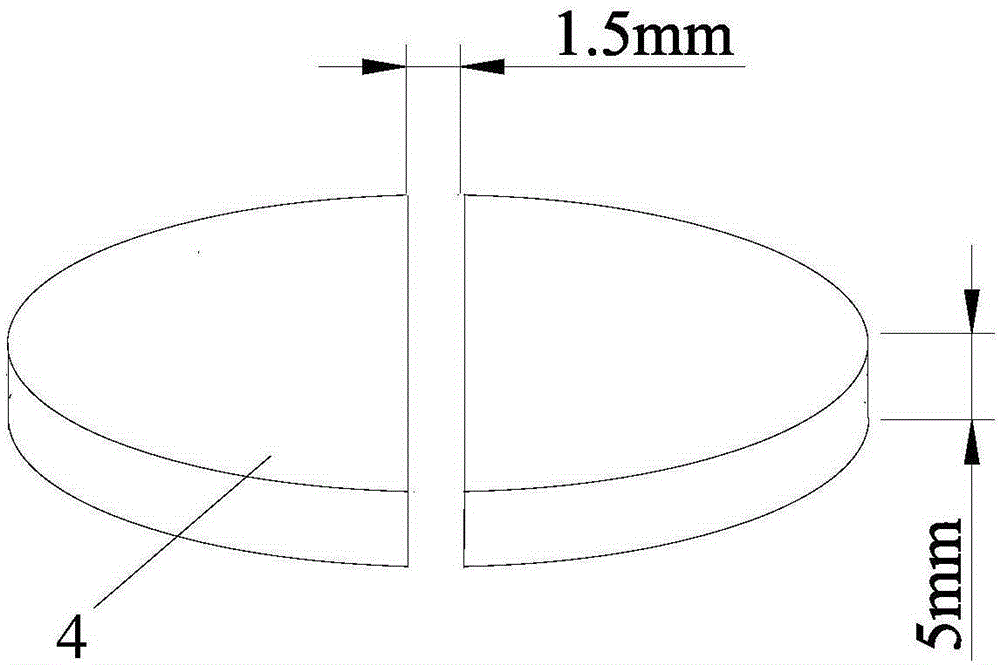

[0038]Two semicircular NdFeB magnets form a group, with a diameter of 25mm and a thickness of 5mm. The N pole and S pole face the same direction, and the distances between the centers of the two semicircles are 1.5mm, 3mm, and 4mm respectively. . Use the WT10A Gauss meter to measure the magnetic field strength between the two semicircles, which are 8800 Gauss, 7000 Gauss and 6500 Gauss respectively. Therefore, the distance between the centers of the two semicircles in the device for pre-purifying fuel oil designed by the present invention is 1.5 mm. Such as figure 1 .

Embodiment 3

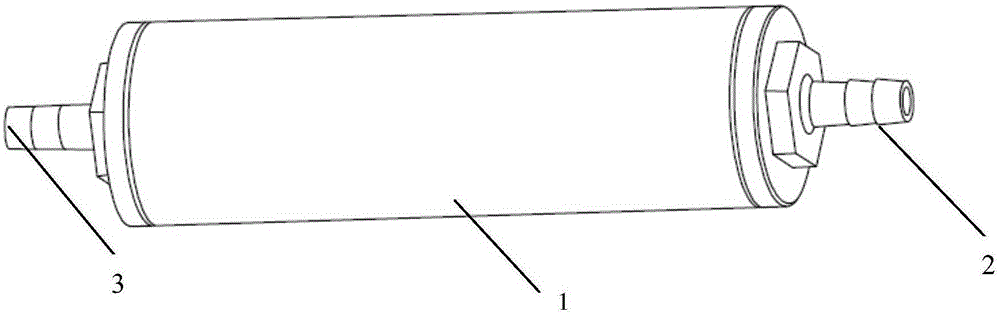

[0040] see Figure 2 to Figure 4 . A device for purifying fuel oil at the front of the engine. The shell of the device is a shell 1 in the shape of a circular tube. The two ends of the circular tube are respectively the oil inlet 2 and the oil outlet 3. In the shell of the alumina tube, 8 sets of NdFeB magnets are placed alternately. sheet and 9 tin-antimony alloy catalytic elements 5; the outer diameter of the shell is 38mm, and the length (not including the oil inlet and oil outlet) is 160mm. The NdFeB magnet sheet 4 is in the shape of a semicircle, two semicircular NdFeB magnet sheets form a group, the N pole and the S pole face the same direction, and the distance between the centers of the two semicircles is 1.5mm;

[0041] see Figure 7 There is a built-in sleeve 7 (PVC material) in the shape of a hollow tube in the shell of the fuel purification device. The inner wall of the sleeve is provided with radially opposite protrusions, and two semicircular NdFeB magnets are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com